Permanent Magnets

-

Neodymium Ring Magnets Manufacturer

Product Name: Permanent Neodymium Ring Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium ring magnet or customized

Magnetization Direction: Thickness, Length, Axially, Diametre, Radially, Multipolar

-

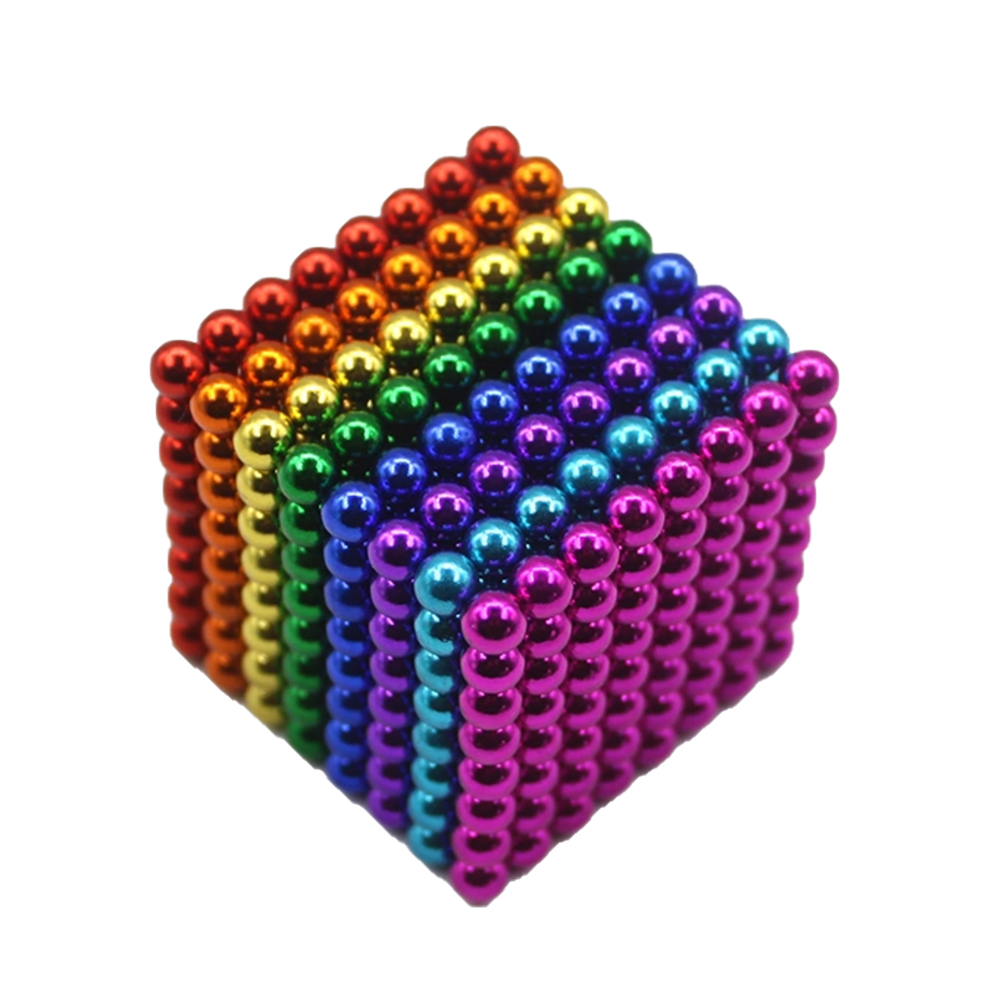

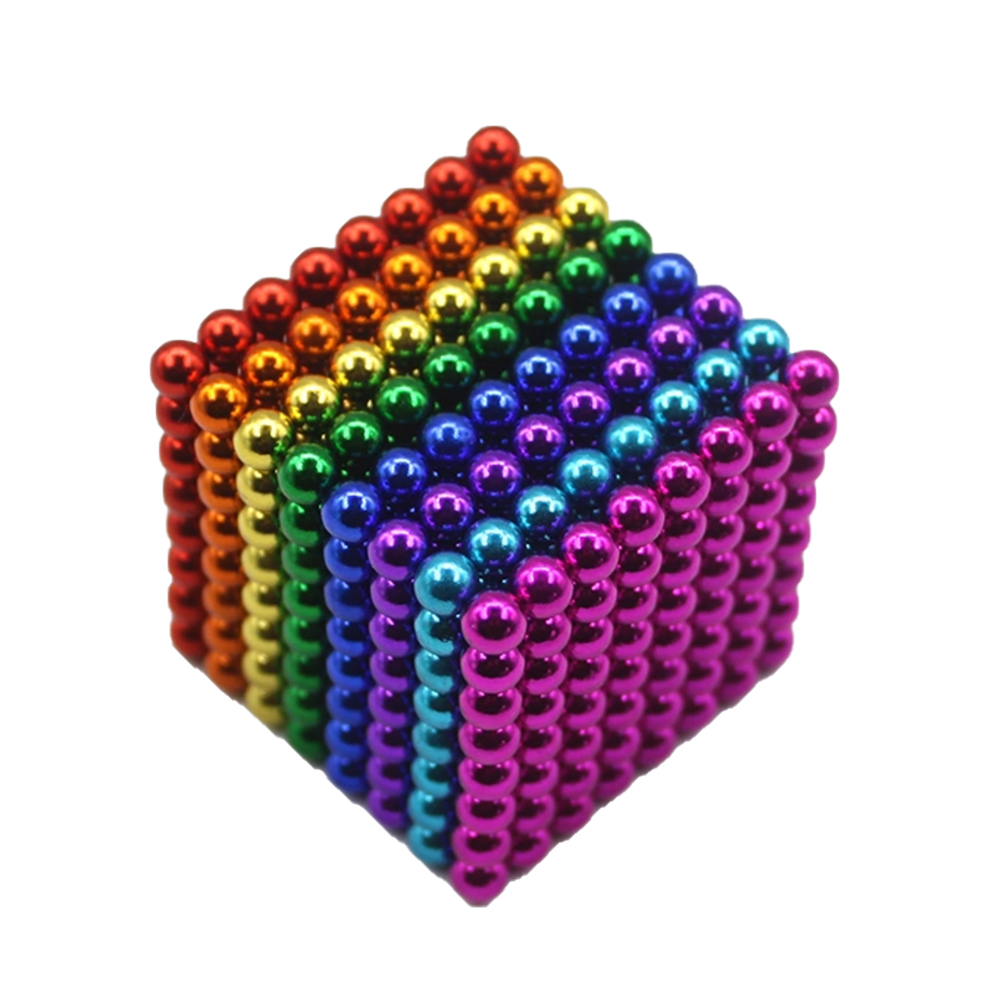

Strong NdFeB Sphere Magnets

Description: Neodymium Sphere Magnet/ Ball Magnet

Grade: N35-N52(M,H,SH,UH,EH,AH)

Shape: ball, sphere, 3mm, 5mm etc.

Coating: NiCuNi, Zn, AU, AG, Epoxy etc.

Packaging: Color Box, Tin Box, Plastic Box etc.

-

Strong Neo Magnets with 3M Adhesive

Grade: N35-N52(M,H,SH,UH,EH,AH)

Shape:Disc, Block etc.

Adhesive Type: 9448A, 200MP, 468MP, VHB, 300LSE etc

Coating: NiCuNi, Zn, AU, AG, Epoxy etc.

3M adhesive magnets is used more and more in our daily life. it is made up of neodymium magnet and high quality 3M self-adhesive tape.

-

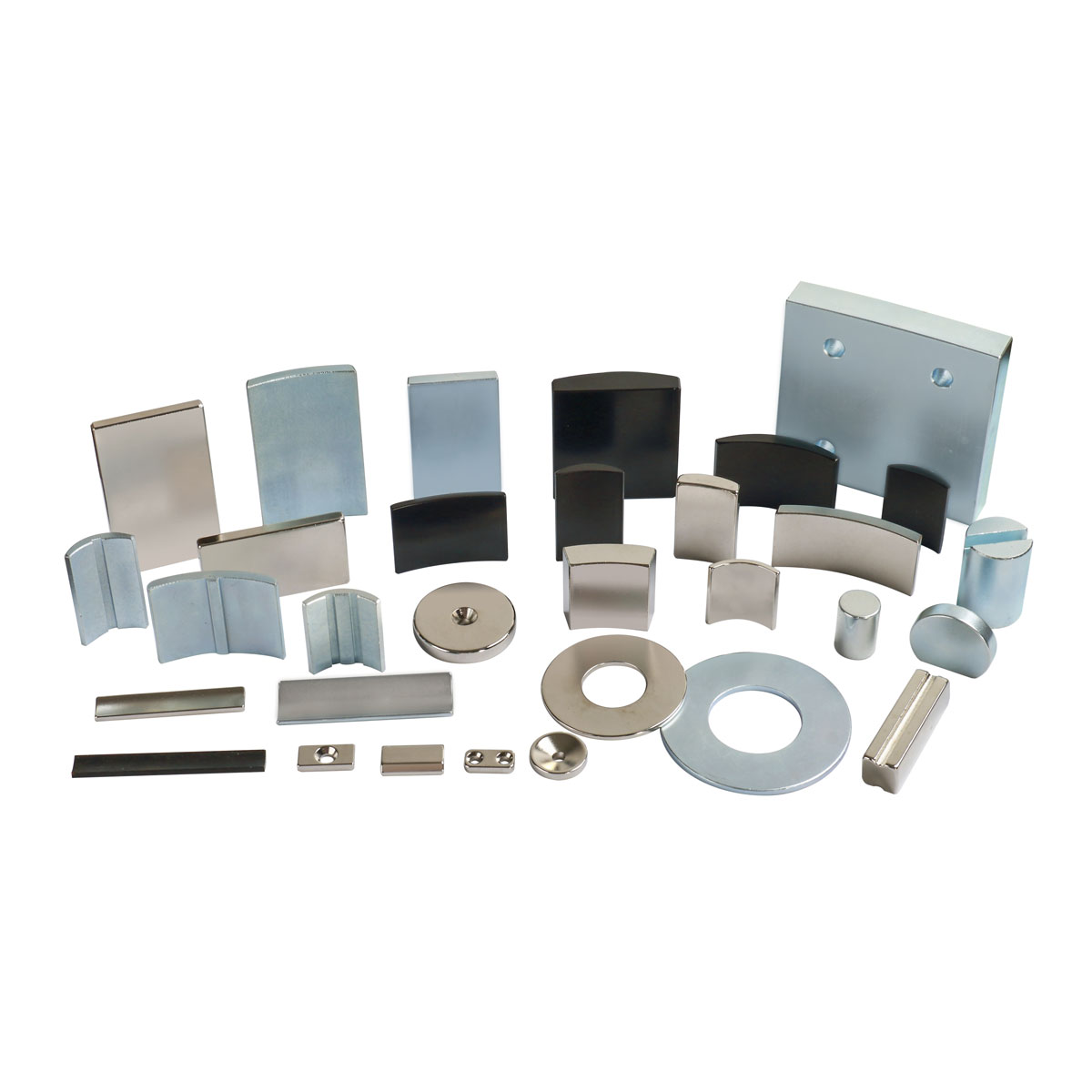

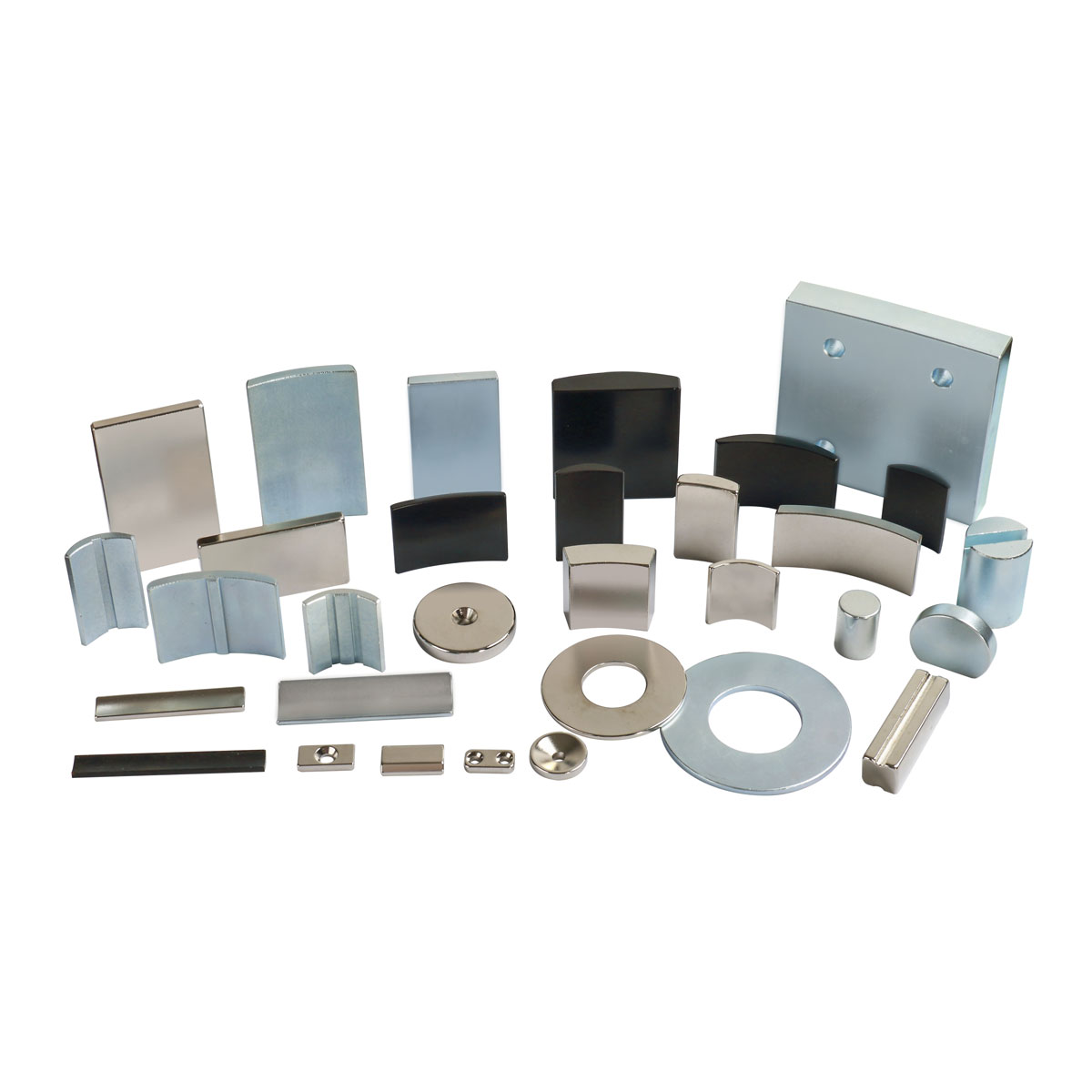

Custom Neodymium Iron Boron Magnets

Product Name: NdFeB Customized Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: As per your request

Lead time: 7-15 days

-

Coatings & Platings Options of Permanent Magnets

Surface Treatment: Cr3+Zn, Color Zinc, NiCuNi, Black Nickel, Aluminium, Black Epoxy, NiCu+Epoxy, Aluminium+Epoxy, Phosphating, Passivation, Au, AG etc.

Coating Thickness: 5-40μm

Working Temperature: ≤250 ℃

PCT: ≥96-480h

SST: ≥12-720h

Please contact our expert for coating options!

-

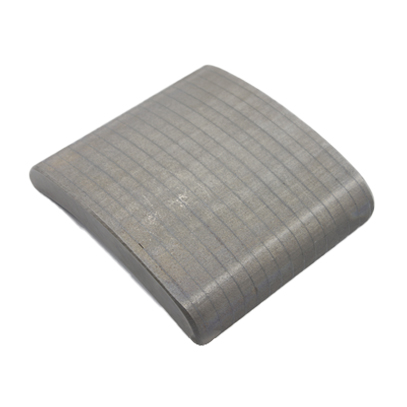

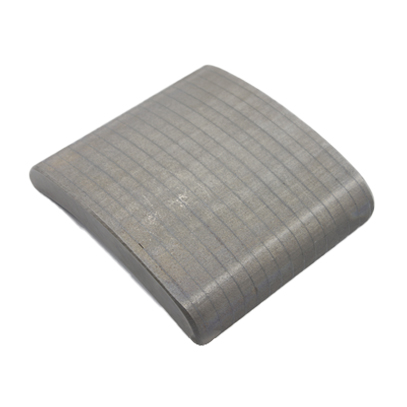

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

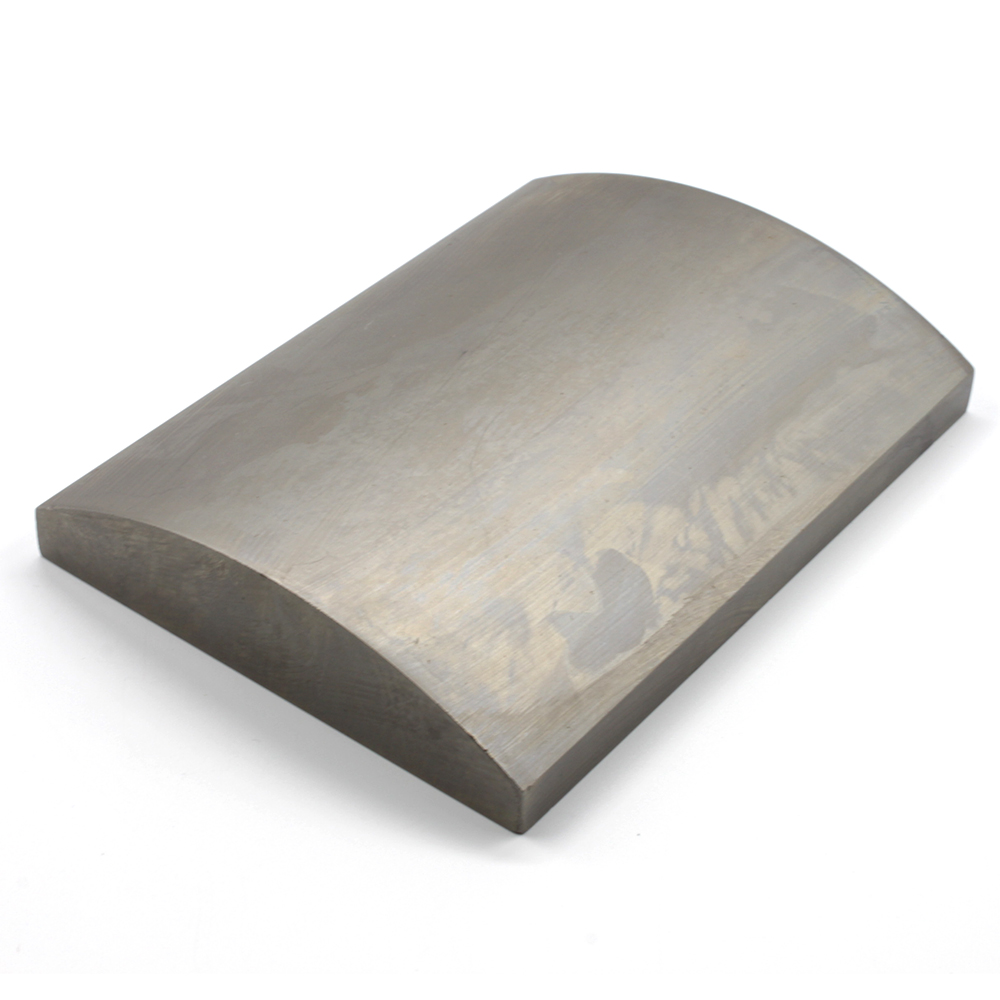

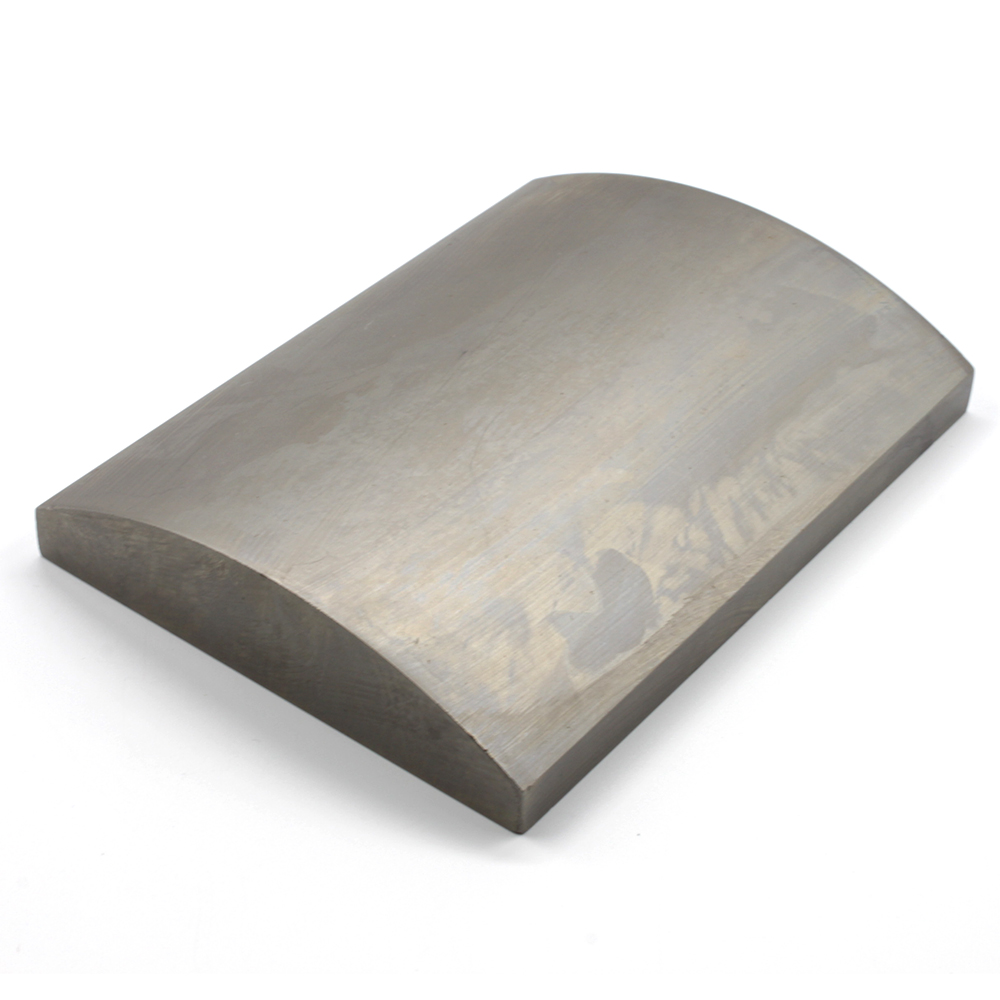

N38H Neodymium Magnets for Linear Motors

Product Name: Linear Motor Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium block magnet or customized -

Halbach Array Magnetic System

Halbach array is a magnet structure, which is an approximate ideal structure in engineering. The goal is to generate the strongest magnetic field with the smallest number of magnets. In 1979, when Klaus Halbach, an American scholar, conducted electron acceleration experiments, he found this special permanent magnet structure, gradually improved this structure, and finally formed the so-called “Halbach” magnet.

-

Rare Earth Magnetic Rod & Applications

Magnetic rods are mainly used to filter iron pins in raw materials; Filter all kinds of fine powder and liquid, iron impurities in semi liquid and other magnetic substances. At present, it is widely used in chemical industry, food, waste recycling, carbon black and other fields.

-

Permanent Magnets used in Automotive Industry

There are many different uses for permanent magnets in automotive applications, including efficiency. The automotive industry is focused on two kinds of efficiency: fuel-efficiency and efficiency on the production line. Magnets help with both.

-

Servo Motor Magnets Manufacturer

The N pole and S pole of the magnet are arranged alternately. One N pole and one s pole are called a pair of poles, and the motors can have any pair of poles. Magnets are used including aluminum nickel cobalt permanent magnets, ferrite permanent magnets and rare earth permanent magnets (including samarium cobalt permanent magnets and neodymium iron boron permanent magnets). The magnetization direction is divided into parallel magnetization and radial magnetization.

-

Wind Power Generation Magnets

Wind energy has become one of the most feasible clean energy sources on earth. For many years, most of our electricity came from coal, oil and other fossil fuels. However, creating energy from these resources causes serious damages to our environment and pollute the air, land and water. This recognition has made many people to turn to green energy as a solution.