Neodymium Iron Boron Block Magnet

Magnetic output: very high strength cost ratio

Anti demagnetization: very high

Relative cost: medium

High-temperature resistance: poor (despite high-temperature rating)

Corrosion resistance: poor

Surface treatment: electroplating can be carried out in a series of surface treatments

Physical properties: very hard and fragile

Machinability: extremely difficult to drill or cut

Application: widely used in many industries

Description: neodymium magnet is more called rare earth magnet (or super magnet). They are permanent magnets made of alloys of various materials such as iron, boron, and neodymium. They are widely used in various industries from electronics to automobiles. These magnets can be bonded or sintered. The latter is more popular because of its better performance.

Neodymium magnets are very strong. We have a variety of neodymium magnets in stock. If you are looking for a specific shape or size, please check out our collection. Our experts will help you.

| Product Name | N42SH F60x10.53x4.0mm Neodymium Block Magnet | |

|

Material

|

Neodymium-Iron-Boron

|

|

| Neodymium magnets are a member of the Rare Earth magnet family and are the most powerful permanent magnets in the world. They are also referred to as NdFeB magnets, or NIB, because they are composed mainly of Neodymium (Nd), Iron (Fe) and Boron (B). They are a relatively new invention and have only recently become affordable for everyday use. | ||

|

Magnet Shape

|

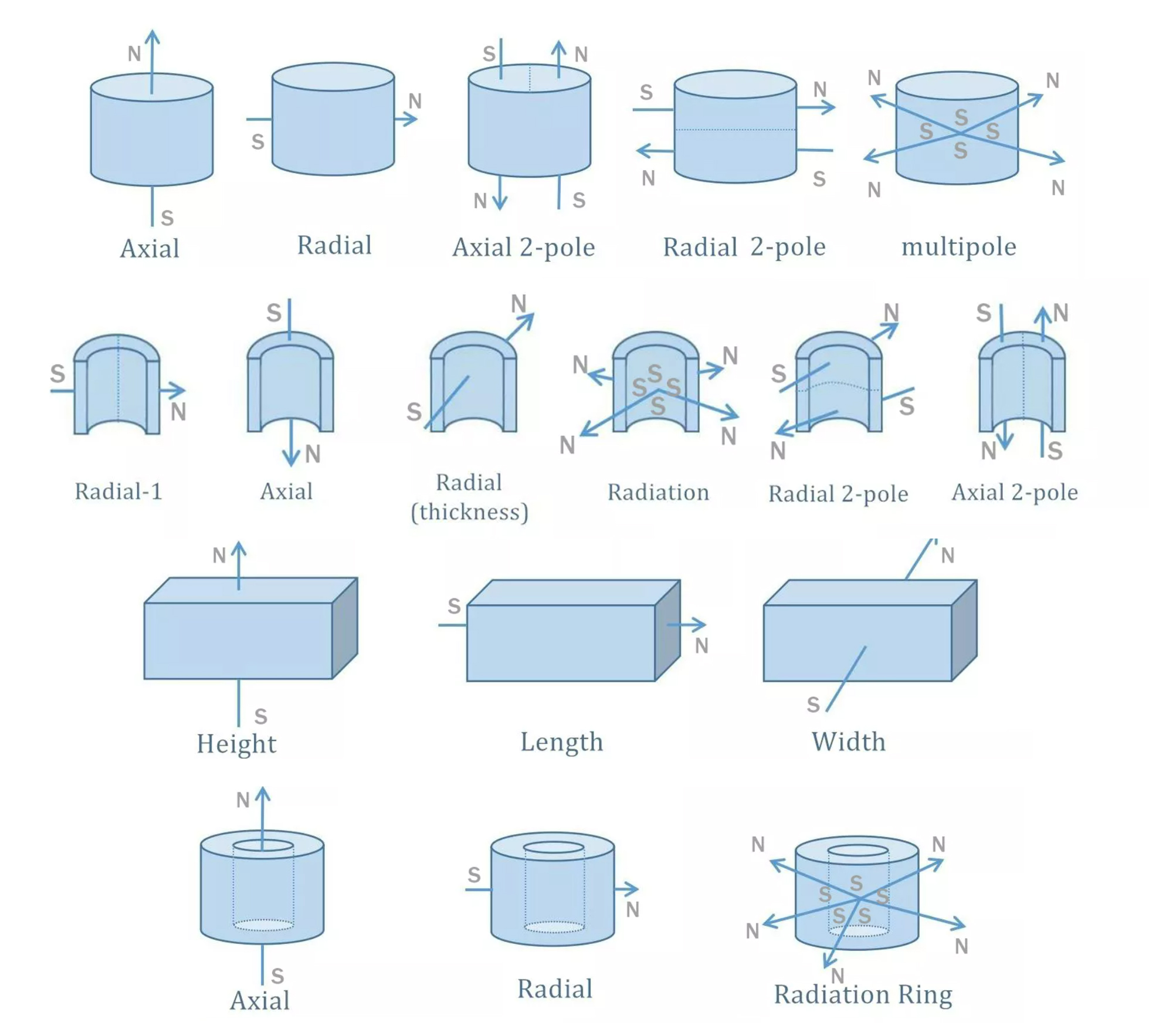

Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid and Irregular shapes and more. Customized shapes are available

|

|

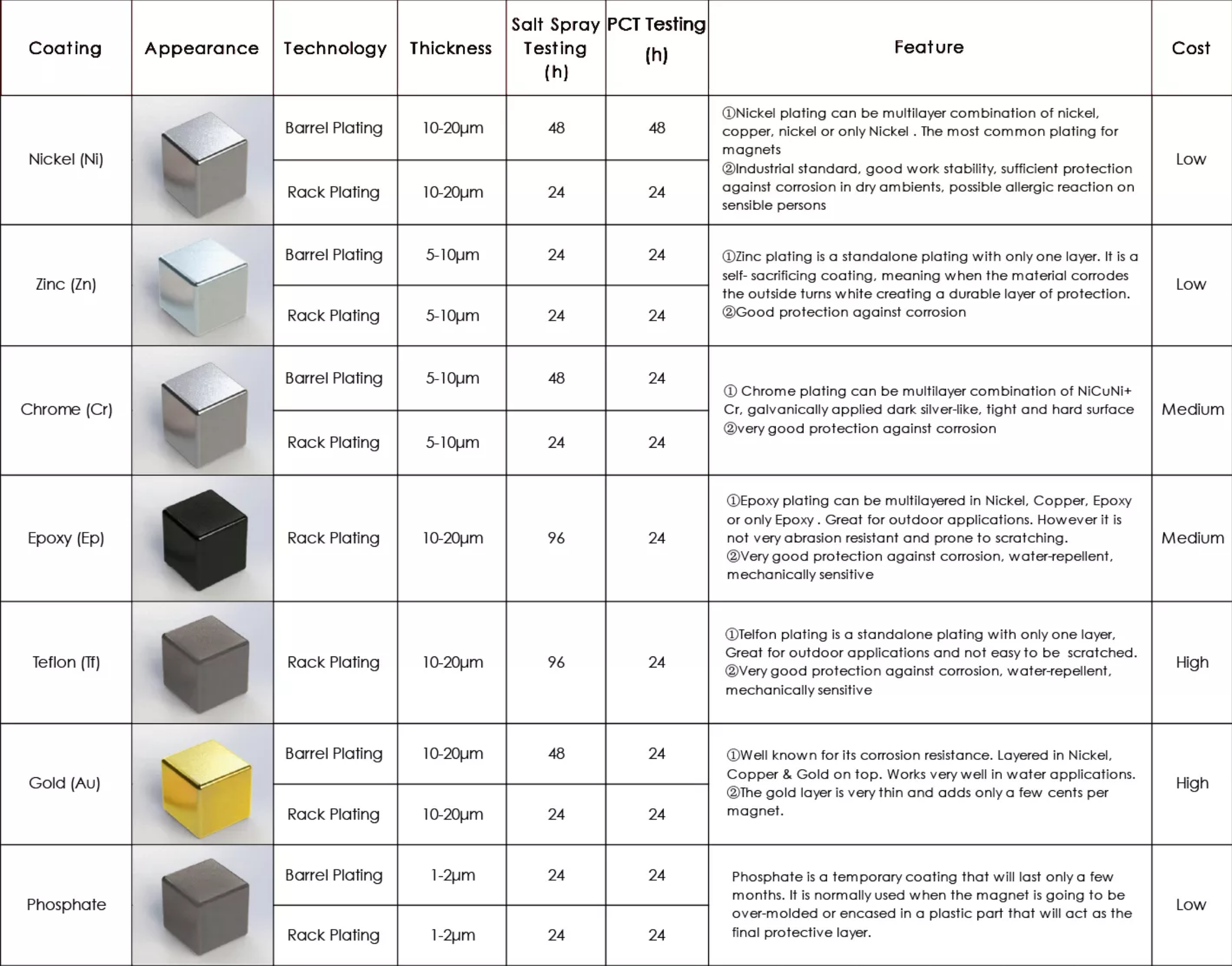

| Magnet coating |

Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper, epoxy, silver and gold.

|

|

| Features |

The most powerful permanent magnet, offers a great return for cost & performance, have the highest field/surface strength(Br), high coercivity(Hc), can be easily formed into various shapes and sizes. Be reactive with moisture and oxygen, usually supplied by plating (Nickel, Zinc, Passivatation, Epoxy coating, etc.).

|

|

|

Applications

|

Sensors, motors, filter automobiles, magnetics holders, loudspeakers, wind generators, medical equipments, etc.

|

|

| Grade & Working Temperature |

Grade

|

Temperature

|

|

N28-N48

|

80°

|

|

|

N50-N55

|

60°

|

|

|

N30M-N52M

|

100°

|

|

|

N28H-N50H

|

120°

|

|

|

N28SH-N48SH

|

150°

|

|

|

N28UH-N42UH

|

180°

|

|

|

N28EH-N38EH

|

200°

|

|

|

N28AH-N33AH

|

200°

|

|

Neodymium magnets can be formed into many shapes and types:

-Arc / Segment / Tile / Curved magnets -Eye Bolt magnets

-Block magnets -Magnetic Hooks / Hook magnets

-Hexagon magnets -Ring magnets

-Countersunk and counterbore magnets -Rod Magnets

-Cube magnets -Adhesive Magnet

-Disc Magnets -Sphere magnets neodymium

-Ellipse & Convex Magnets -Other Magnetic Assemblies

If the magnet is clamped between two mild steel (ferromagnetic) plates, the magnetic circuit is good (there are some leaks on both sides). But if you have two NdFeB Neodymium Magnets, which are arranged side by side in an N-S arrangement (they will be very strongly attracted in this way), you have a better magnetic circuit, with potentially higher magnetic pull, almost no air gap leakage, and the magnet will be close to its maximum possible performance (assuming that the steel will not be magnetically saturated). Further considering this idea, considering the checkerboard effect (-N-S-N-S -, etc.) between two low-carbon steel plates, we can get a maximum tension system, which is only limited by the ability of the steel to carry all the magnetic flux.

Neodymium magnetic blocks are typically used in numerous applications including motors, medical equipment, sensors, holding applications, electronics and automotive. Smaller sizes can also be used simple attaching or holding displays in retail or exhibitions, simple DIY and workshop mounting or holding applications. Their high strength relative to size makes them a very versatile magnet option.