Industries & Applications

-

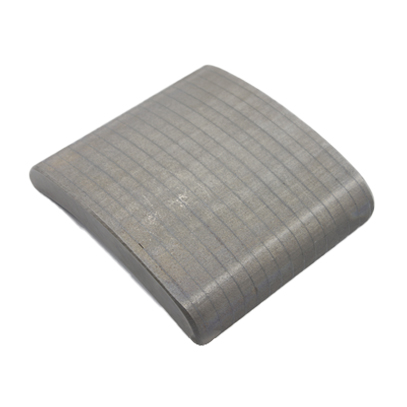

NdFeB Bonded Compressed Ring Magnets with Epoxy Coating

Material: Fast-quenched NdFeB magnetic powder and binder

Grade: BNP-6, BNP-8L, BNP-8SR, BNP-8H, BNP-9, BNP-10, BNP-11, BNP-11L, BNP-12L as per your request

Shape: Block, Ring, Arc, Disc and customized

Size: Customized

Coating: Black /gray epoxy, Parylene

Magnetization direction: Radial, face multipole magnetization, etc

-

N42SH F60x10.53×4.0mm Neodymium Block Magnet

Bar magnets, cube magnets and block magnets are the most common magnet shapes in daily installation and fixed applications. They have perfectly flat surfaces at right angles (90 °). These magnets are square, cube or rectangular in shape and are widely used in holding and mounting applications, and can be combined with other hardware (such as channels) to increase their holding force.

Keywords: Bar Magnet, Cube Magnet, Block Magnet, Rectangular Magnet

Grade: N42SH or customized

Dimension: F60x10.53×4.0mm

Coating: NiCuNi or customized

-

N38SH Flat Block Rare Earth Permanent Neodymium Magnet

Material: Neodymium Magnet

Shape: Neodymium Block Magnet, Big Square Magnet or other shapes

Grade: NdFeB, N35–N52(N, M, H, SH, UH, EH, AH) as per your request

Size: Regular or Customized

Magnetism direction: Customzied Specific Requirements

Coating: Epoxy.Black Epoxy. Nickel.Silver.etc

Working temperature: -40℃~150℃

Processing Service: Cutting, Moulding, Cutting, Punching

Lead Time: 7-30 days

* * T/T, L/C, Paypal and other payment accepted.

** Orders of any customized dimension.

** Worldwide Fast Delivery.

** Quality and price guaranteed.

-

Small Tiny Neodymium Magnet Cube Rare Earth Permanent Magnet

Cube/Block 5.0 x 5.0 x 5.0 mm N35SH Nickel (Ni+Cu+Ni) Neodymium Magnet

1.High intensity NdFeB magnet in a variety of shapes.

2.grades:N33-N52 (M,H,SH,UH,EH)

3.platings:Nickle,Zinc,Cu,etc.

NdFeB magnets are the most powerful and advanced commercialized permanent magnets available today.

Honsen Magnetics has more than 10 years of experience in this field.

We concentrate on Sintered NdFeB magnets and develop them with the help of an experienced engineer and a dedicated sales team.

* Physical advantages: This material is hard,brittle, and easily corroded, but we have many surface treatments to protect the surface, such as Nickel,Nickel-Copper-Nickel,Znic,Black&Grey epoxy coating,Aluminium coating,Tin,Silver, and so on.

It has high stability even at high temperatures; the working stability is less than 80 degrees Celsius for low Hcj and more than 200 degrees Celsius for high Hcj.

The temperature coefficients of Br are -0.09–0.13% and Hcj are -0.5–0.8%/degree C. -

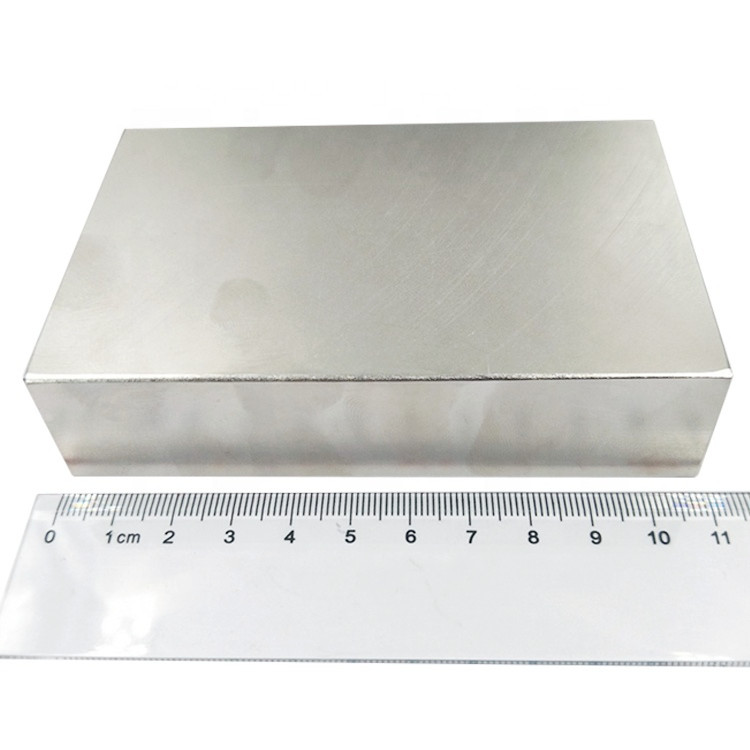

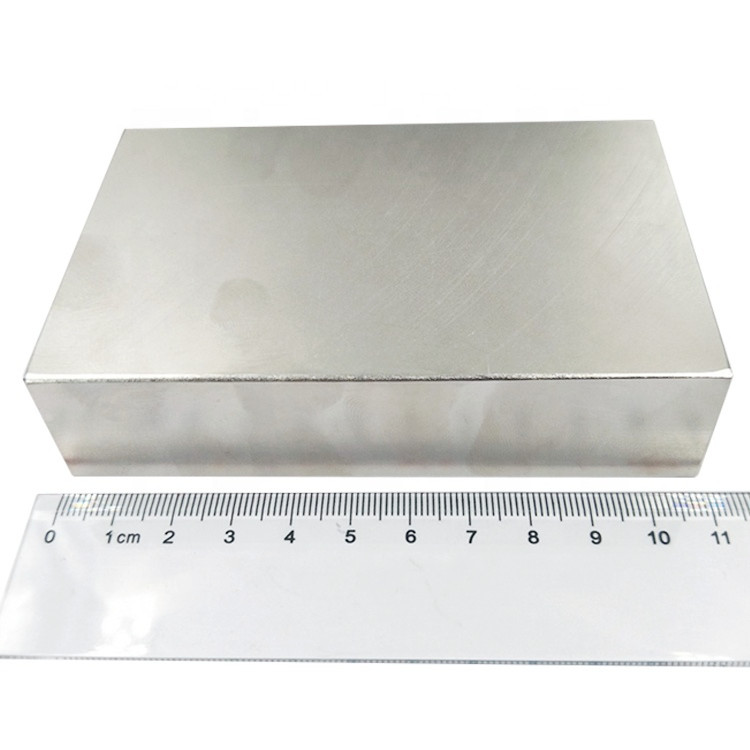

Large Permanent Neodymium Block Magnet Manufacturer N35-N52 F110x74x25mm

Material: Neodymium Magnet

Shape: Neodymium Block Magnet, Big Square Magnet or other shapes

Grade: NdFeB, N35–N52(N, M, H, SH, UH, EH, AH) as per your request

Size: 110x74x25 mm or Customized

Magnetism direction: Customzied Specific Requirements

Coating: Epoxy.Black Epoxy. Nickel.Silver.etc

Samples and Trial Orders Are Most Welcome !

-

N52 Rare Earth Permanent Neodymium Iron Boron Cube Block Magnet

Grade: N35-N52 (N,M,H,SH,UH,EH,AH)

Dimension: To be Customized

Coating: To be Customized

MOQ: 1000pcs

Lead time: 7-30days

Packaging: Foam protecter box ,inner box ,then into the standard export carton

Transportation: Ocean,Land,Air,by train

HS Code: 8505111000

-

Powerful Rare Earth Permanent Neodymium Block Magnet

- Product Name: Neodymium block magnet

- Shape: Block

- Application: Industrial Magnet

- Processing Service: Cutting, Moulding, Cutting, Punching

- Grade: N35-N52( M, H, SH, UH, EH, AH series ), N35-N52 (M.H.SH.UH.EH.AH)

- Delivery Time: 7-30 days

- Material: Permanent Neodymium magnet

- Working temperature: -40℃~80℃

- Size: Customized Magnet Size

-

Neodymium Cylinder/Bar/Rod Magnets

Product Name: Neodymium Cylinder Magnet

Material: Neodymium Iron Boron

Dimension: Customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Magnetization Direction: As per your request

-

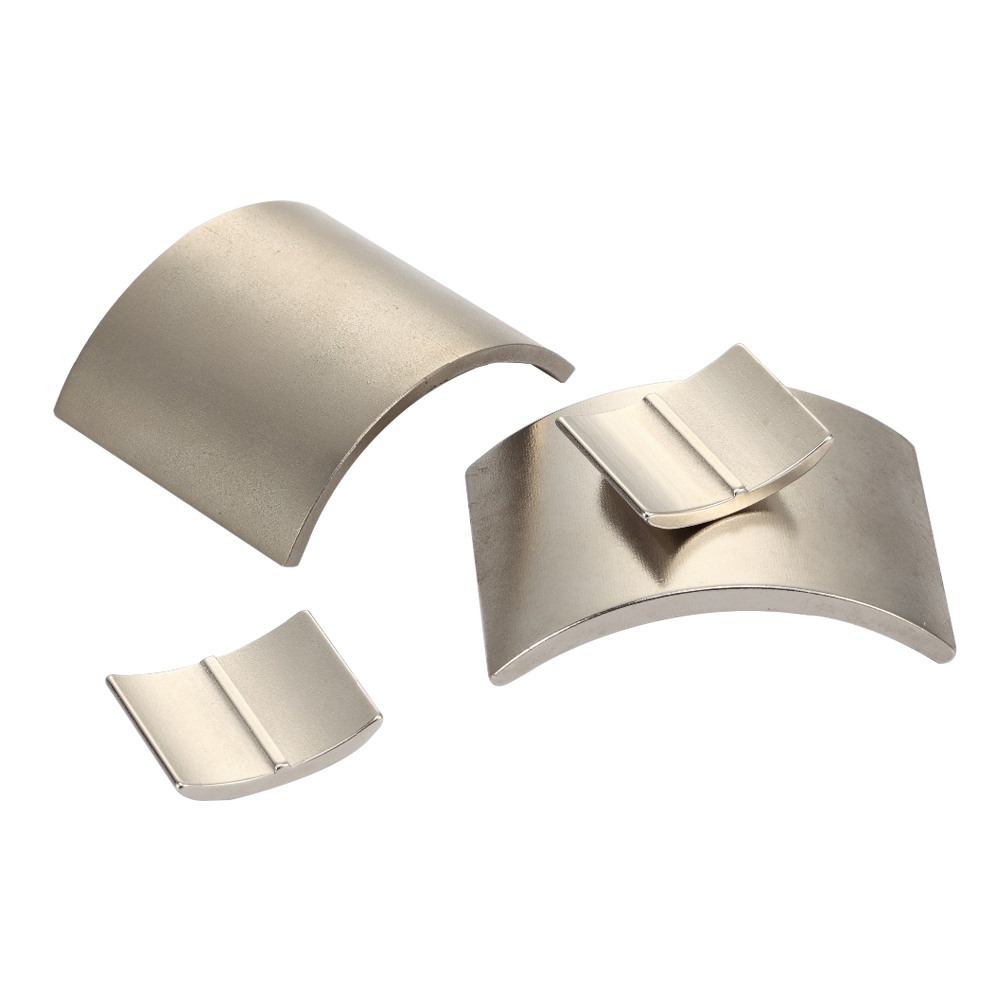

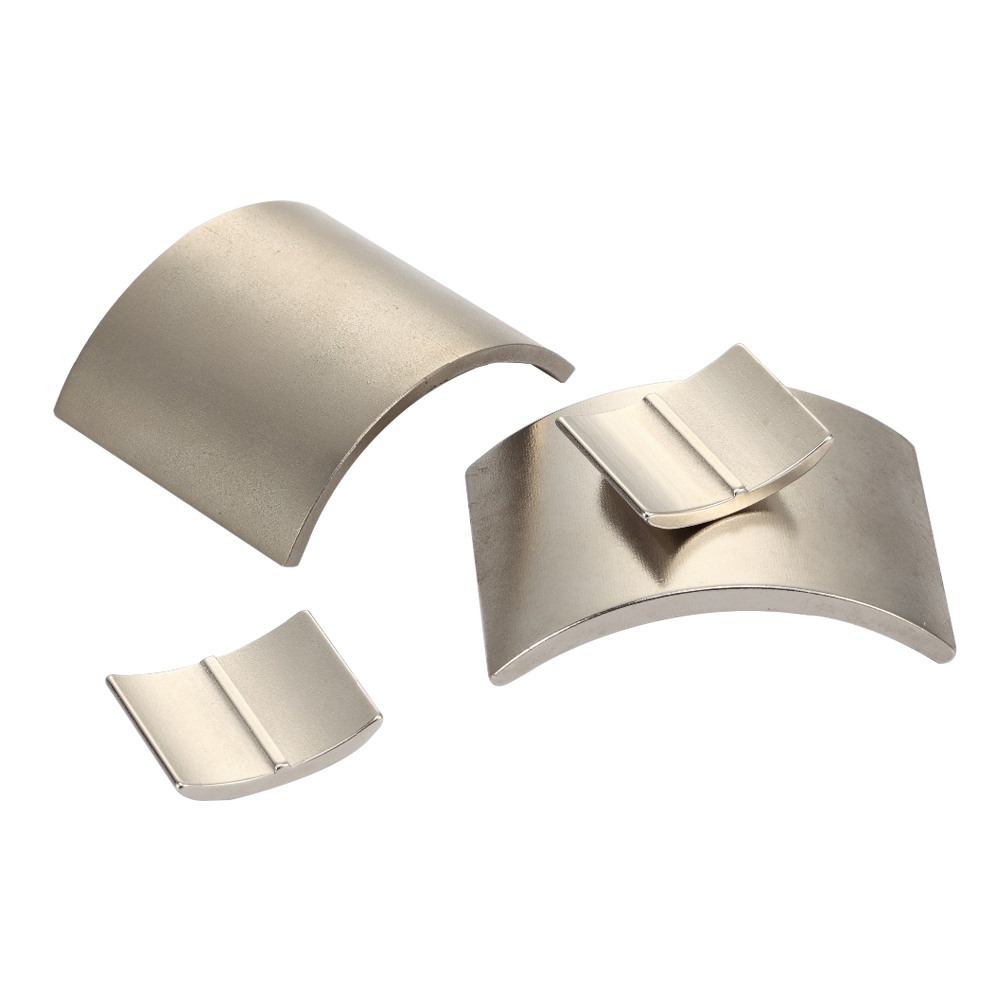

Neodymium (Rare Earth) Arc/Segment Magnet for Motors

Product Name: Neodymium Arc/Segment/Tile Magnet

Material: Neodymium Iron Boron

Dimension: Customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Magnetization Direction: As per your request

-

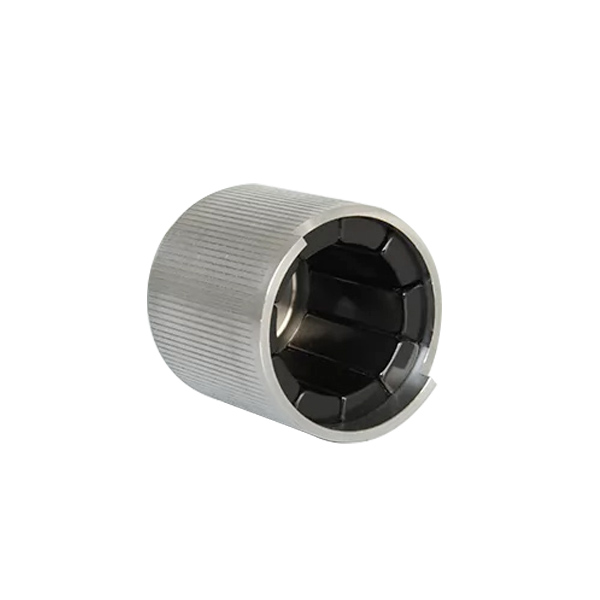

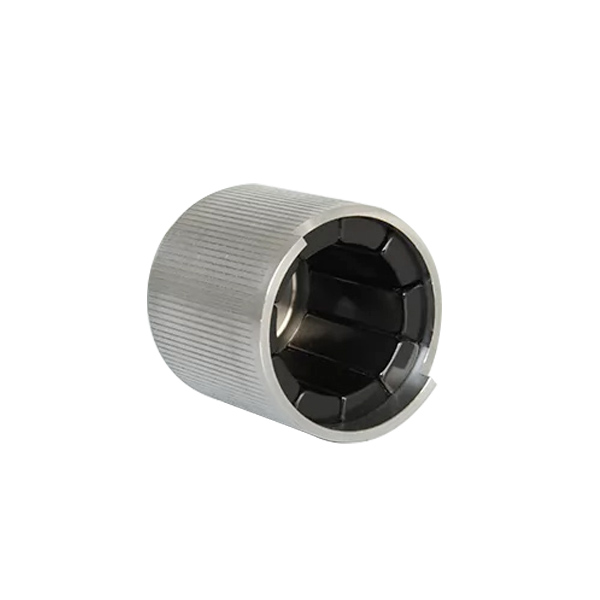

Magnetic Rotor Assemblies for High-Speed Electric Motors

Magnetic rotor, or permanent magnet rotor is the non stationary part of a motor. The rotor is the moving part in an electric motor, generator and more. Magnetic rotors are designed with multiple poles. Each pole alternates in polarity (north & south). Opposite poles rotate about a central point or axis (basically, a shaft is located in the middle). This is the principal design for rotors. Rare-earth permanent magnetic motor has a series of advantages, such as small size, light weight, high efficiency and good characteristics. Its applications are very extensive and extend all over fields of aviation, space, defense, equipment manufacturing, industrial and agricultural production and daily life.

-

Permanent Magnetic Couplings for Drive Pump & magnetic mixers

Magnetic couplings are non-contact couplings that use a magnetic field to transfer torque, force or movement from one rotating member to another. The transfer takes place through a non-magnetic containment barrier without any physical connection. The couplings are opposing pairs of discs or rotors embedded with magnets.

-

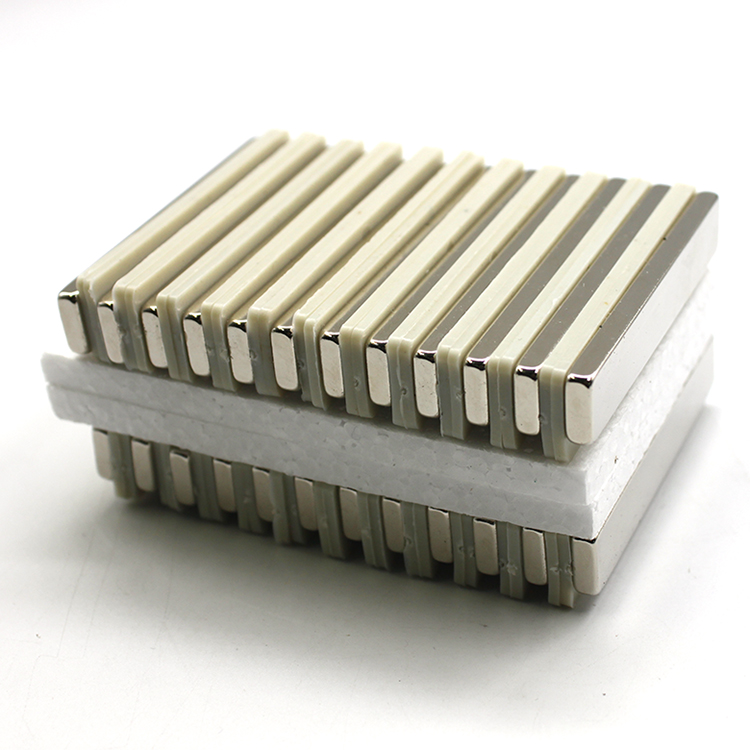

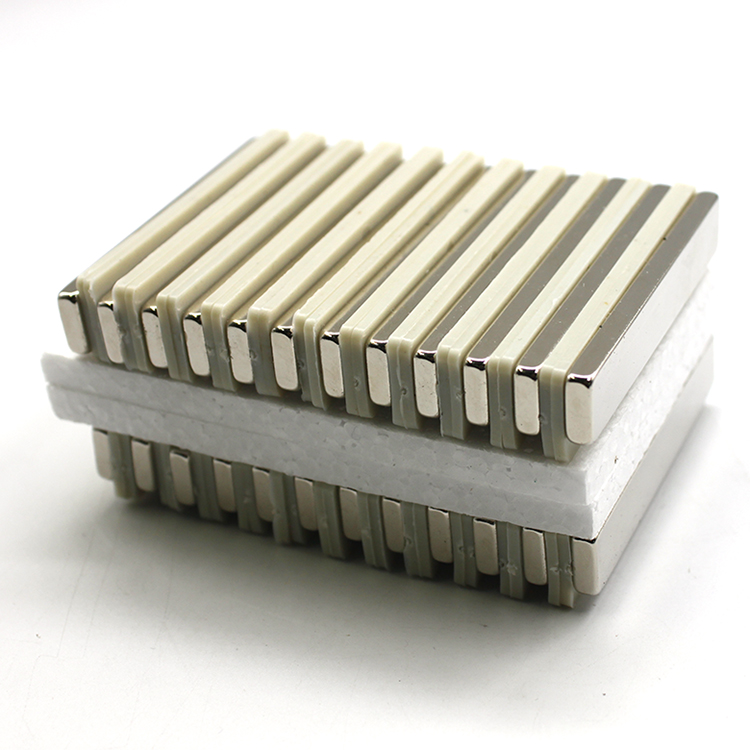

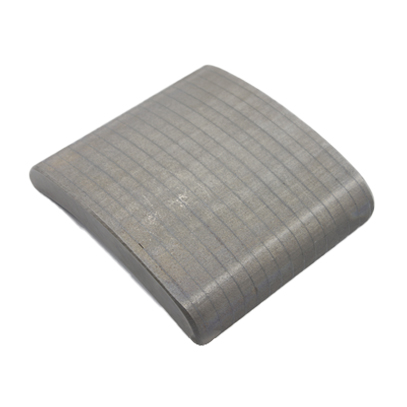

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.