Magnets by Applications

Magnetic materials from Honsen Magnetics have different applications in different industries. Neodymium iron boron magnets, also known as neodymium magnets, are the strongest type of permanent magnets available. They are widely used in electric motors, wind turbines, hard disk drives, loudspeakers and magnetic resonance imaging machines. Ferrite magnets, which are composed of iron oxide and ceramic materials. They are cost-effective and have good resistance to demagnetization. Due to their low cost and high magnetic stability, ferrite magnets find applications in motors, loudspeakers, magnetic separators, and magnetic resonance imaging (MRI) equipment. SMCo magnets or Samarium Cobalt magnets are known for their high corrosion resistance and high temperature stability. These magnets are commonly used in aerospace applications, industrial motors, sensors and magnetic couplings. In addition to the various magnet types, magnetic assemblies play a vital role in many applications. Magnetic components include products such as magnetic chucks, magnetic encoders and magnetic lifting systems. These components use magnets to create specific functions or enhance the performance of machines and equipment. Magnetic components are essential components in many electronic devices. They include items such as magnetic coils, transformers, and inductors. These components are used in power supplies, electric vehicles, telecommunications systems and other electronic equipment to control and manipulate magnetic fields.-

Magnetic Name Badge Automatic Production

Product Name:Magnetic Name Badge

Material: Neodymium Magnet+Steel Plate+Plastic

Dimension: Standard or customized

Color: Standard or customized

Shape: Rectangular, Round or customized

The Magnetic Name Badge belongs to a new type of badge. The Magnetic Name Badge uses magnetic principle to avoid damaging clothes and stimulating skin when wearing ordinary badge products. It is fixed on both sides of clothes by the principle of opposite attraction or magnetic blocks, which is firm and safe. Through the rapid replacement of labels, the service life of products is greatly extended.

-

Sintered NdFeB Block / Cube / Bar Magnets Overview

Description: Permanent Block Magnet, NdFeB Magnet, Rare Earth Magnet, Neo Magnet

Grade: N52, 35M, 38M, 50M, 38H, 45H, 48H, 38SH, 40SH, 42SH, 48SH, 30UH, 33UH, 35UH, 45UH, 30EH, 35EH, 38EH, 42EH etc

Applications: EPS, Pump Motor, Starter Motor , Roof Motor, ABS sensor, Ignition Coil, Loudspeakers etc Industrial Motor, Linear Motor, Compressor Motor, Wind turbine, Rail Transit Traction Motor etc.

-

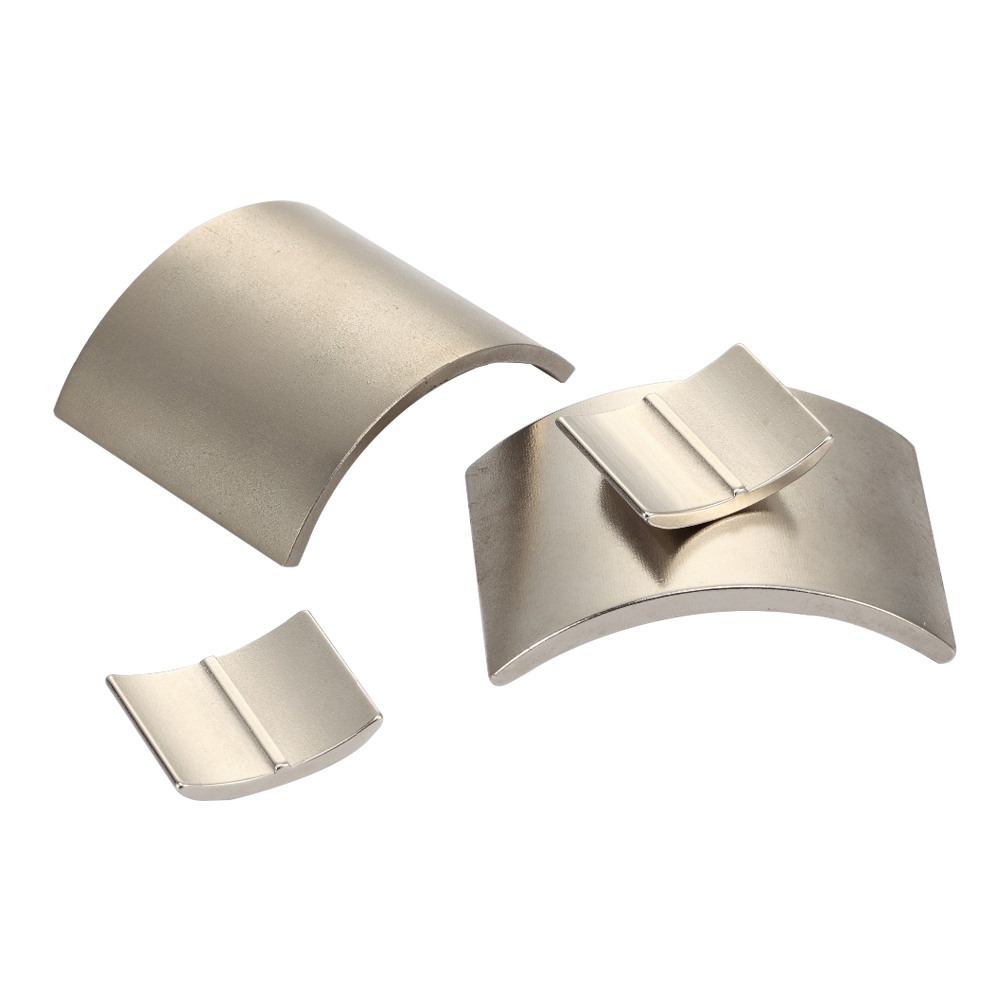

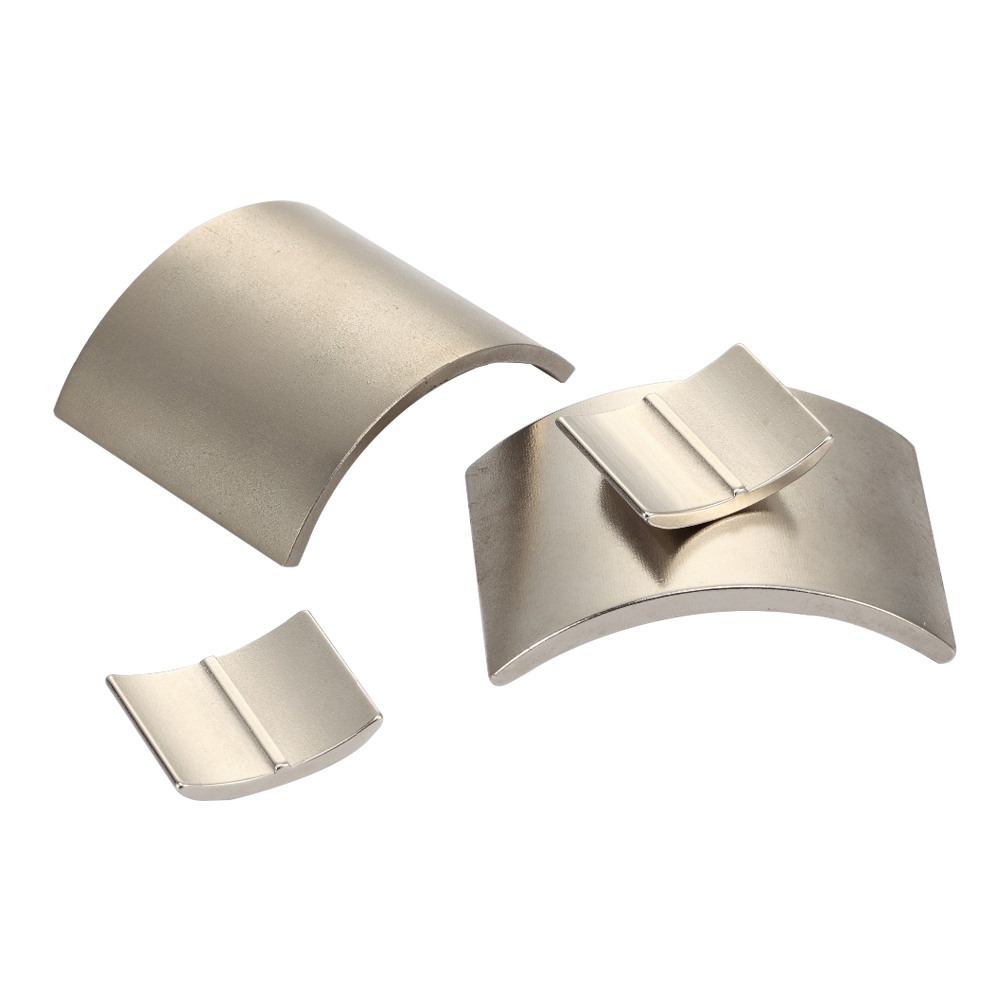

Neodymium (Rare Earth) Arc/Segment Magnet for Motors

Product Name: Neodymium Arc/Segment/Tile Magnet

Material: Neodymium Iron Boron

Dimension: Customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Magnetization Direction: As per your request

-

Countersunk Magnets

Product Name: Neodymium Magnet with Countersunk/Countersink Hole

Material: Rare Earth Magnets/NdFeB/ Neodymium Iron Boron

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Customized -

Neodymium Ring Magnets Manufacturer

Product Name: Permanent Neodymium Ring Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium ring magnet or customized

Magnetization Direction: Thickness, Length, Axially, Diametre, Radially, Multipolar

-

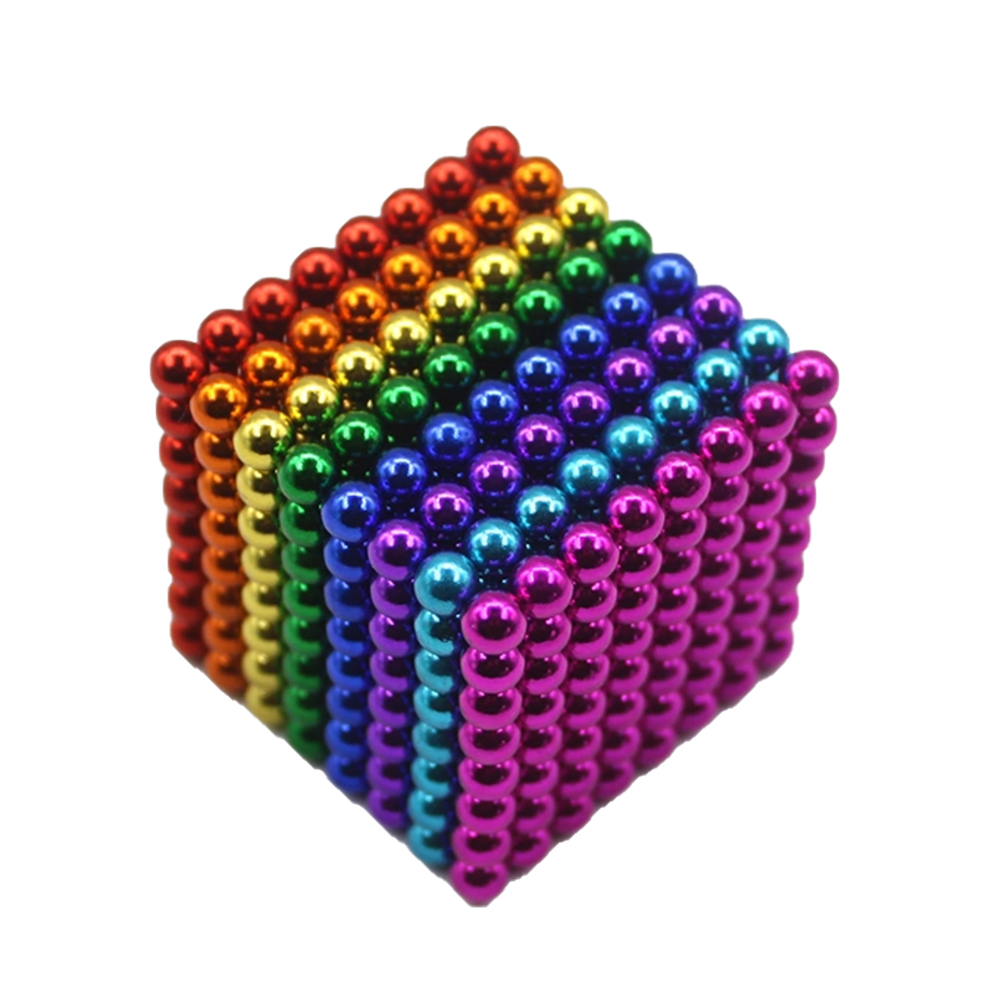

Strong NdFeB Sphere Magnets

Description: Neodymium Sphere Magnet/ Ball Magnet

Grade: N35-N52(M,H,SH,UH,EH,AH)

Shape: ball, sphere, 3mm, 5mm etc.

Coating: NiCuNi, Zn, AU, AG, Epoxy etc.

Packaging: Color Box, Tin Box, Plastic Box etc.

-

Strong Neo Magnets with 3M Adhesive

Grade: N35-N52(M,H,SH,UH,EH,AH)

Shape:Disc, Block etc.

Adhesive Type: 9448A, 200MP, 468MP, VHB, 300LSE etc

Coating: NiCuNi, Zn, AU, AG, Epoxy etc.

3M adhesive magnets is used more and more in our daily life. it is made up of neodymium magnet and high quality 3M self-adhesive tape.

-

Custom Neodymium Iron Boron Magnets

Product Name: NdFeB Customized Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: As per your request

Lead time: 7-15 days

-

Neodymium Channel Magnet Assemblies

Product Name: Channel Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Rectangular, Round base or customized

Application: Sign and Banner Holders – License Plate Mounts – Door Latches - Cable Supports -

Rubber Coated Magnets with Countersunk & Thread

Rubber coated magnet is to wrap a layer of rubber on the outer surface of the magnet, which is usually wrapped with sintered NdFeB magnets inside, magnetic conducting iron sheet and rubber shell outside. The durable rubber shell can ensure the hard, brittle and corrosive magnets to avoid damage and corrosion. It is suitable for indoor and outdoor magnetic fixation applications, such as for vehicle surfaces.

-

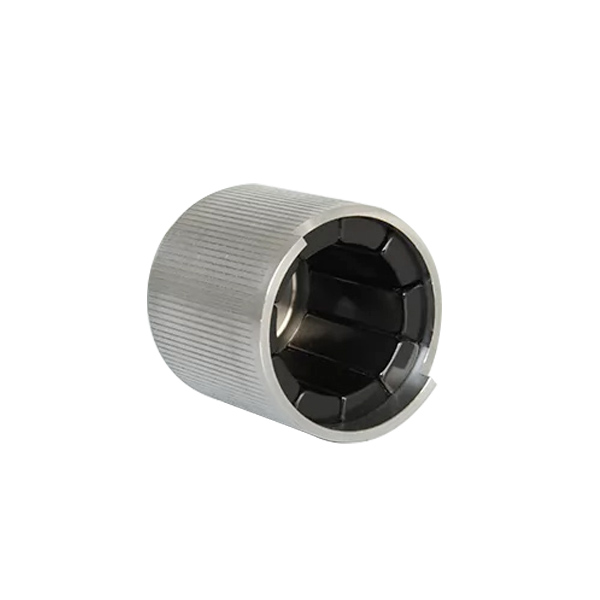

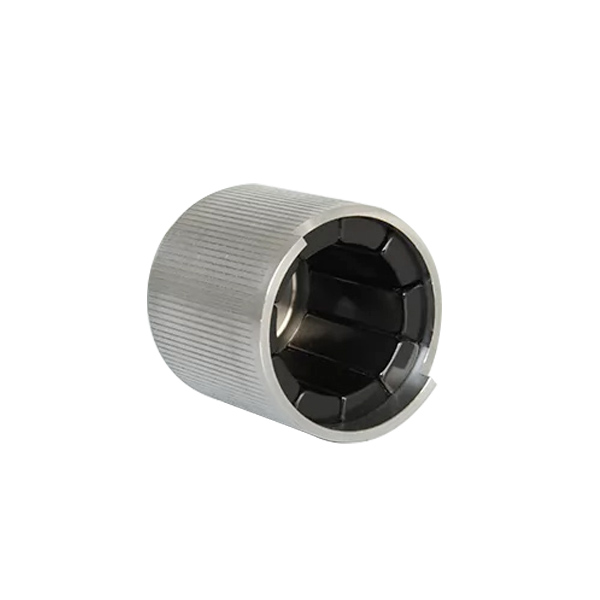

Magnetic Rotor Assemblies for High-Speed Electric Motors

Magnetic rotor, or permanent magnet rotor is the non stationary part of a motor. The rotor is the moving part in an electric motor, generator and more. Magnetic rotors are designed with multiple poles. Each pole alternates in polarity (north & south). Opposite poles rotate about a central point or axis (basically, a shaft is located in the middle). This is the principal design for rotors. Rare-earth permanent magnetic motor has a series of advantages, such as small size, light weight, high efficiency and good characteristics. Its applications are very extensive and extend all over fields of aviation, space, defense, equipment manufacturing, industrial and agricultural production and daily life.

-

Permanent Magnetic Couplings for Drive Pump & magnetic mixers

Magnetic couplings are non-contact couplings that use a magnetic field to transfer torque, force or movement from one rotating member to another. The transfer takes place through a non-magnetic containment barrier without any physical connection. The couplings are opposing pairs of discs or rotors embedded with magnets.