Magnets by Applications

Magnetic materials from Honsen Magnetics have different applications in different industries. Neodymium iron boron magnets, also known as neodymium magnets, are the strongest type of permanent magnets available. They are widely used in electric motors, wind turbines, hard disk drives, loudspeakers and magnetic resonance imaging machines. Ferrite magnets, which are composed of iron oxide and ceramic materials. They are cost-effective and have good resistance to demagnetization. Due to their low cost and high magnetic stability, ferrite magnets find applications in motors, loudspeakers, magnetic separators, and magnetic resonance imaging (MRI) equipment. SMCo magnets or Samarium Cobalt magnets are known for their high corrosion resistance and high temperature stability. These magnets are commonly used in aerospace applications, industrial motors, sensors and magnetic couplings. In addition to the various magnet types, magnetic assemblies play a vital role in many applications. Magnetic components include products such as magnetic chucks, magnetic encoders and magnetic lifting systems. These components use magnets to create specific functions or enhance the performance of machines and equipment. Magnetic components are essential components in many electronic devices. They include items such as magnetic coils, transformers, and inductors. These components are used in power supplies, electric vehicles, telecommunications systems and other electronic equipment to control and manipulate magnetic fields.-

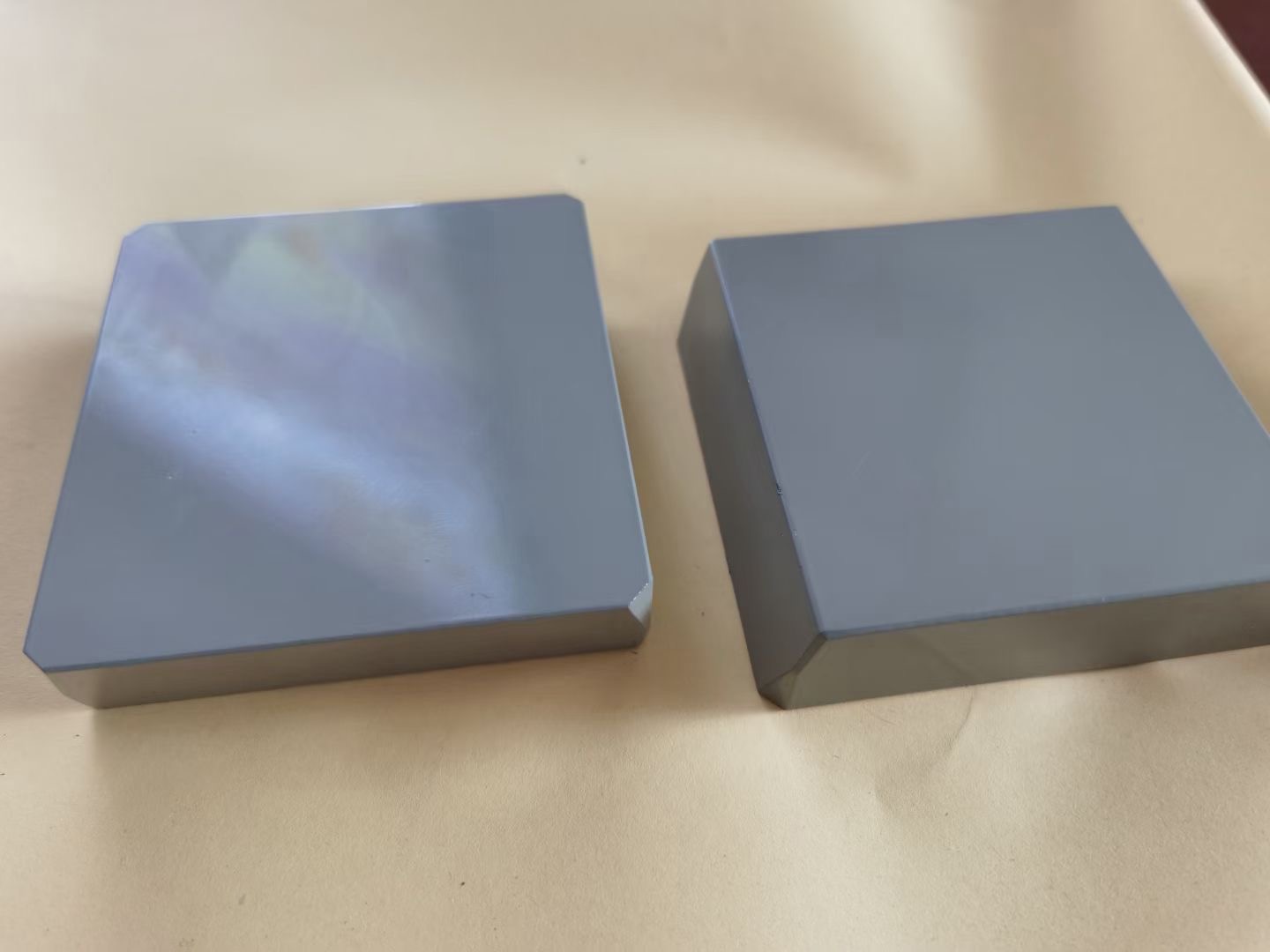

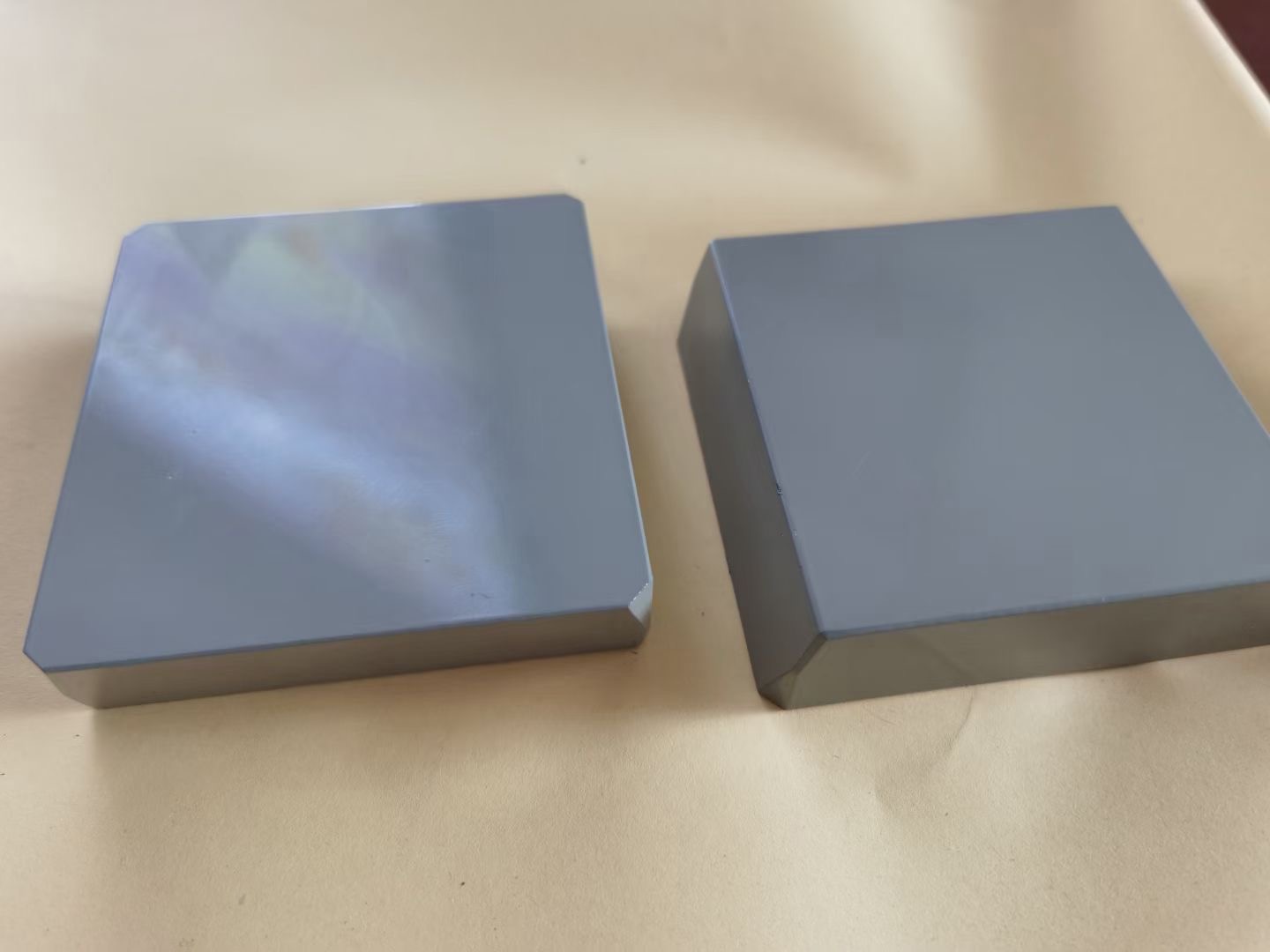

Super Strong N50 Sintered Neodymium Magnet Block Square

Specifications (1”=25.4mm; 1lbs=0.453kg)

Materials: NdFeB

Grade N42 or other high grade

Dimensions(mm): 2″*2″1/2″ squar magnets

Plating: Zinc plated

Br:1.28-1.34T

Hcb ≥ 923 KA/m

Hcj ≥ 955 KA/m

(BH)max:318-334KJ/M3

Curie Temp.310℃

Working temperture : 80℃

Tolerance:+0.1mm/±0.05mm

Magnetizing:Magnetized in pair, half with N on outersid face, half

with S on outerside face -

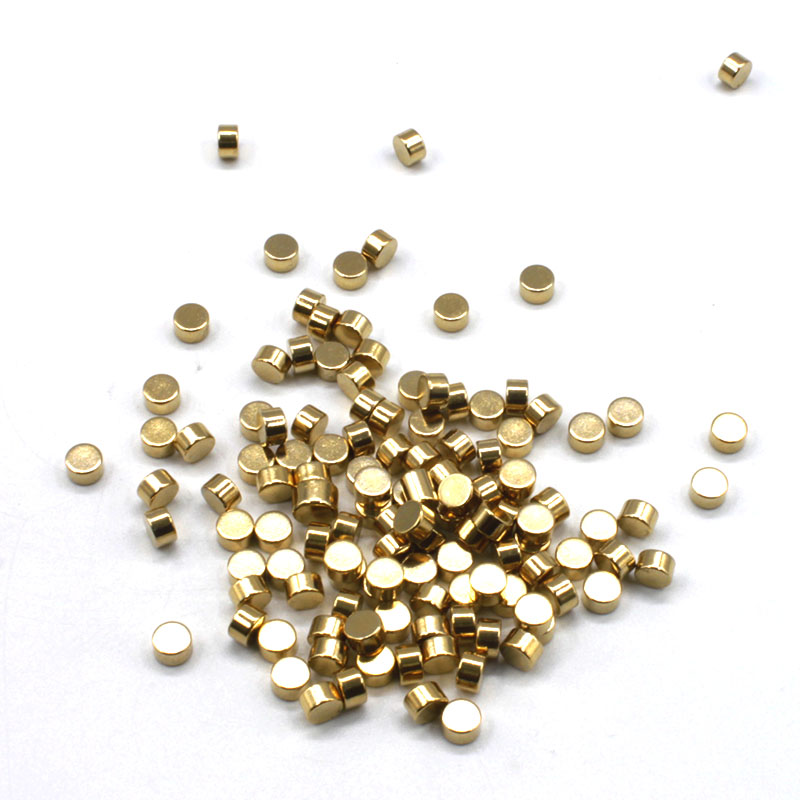

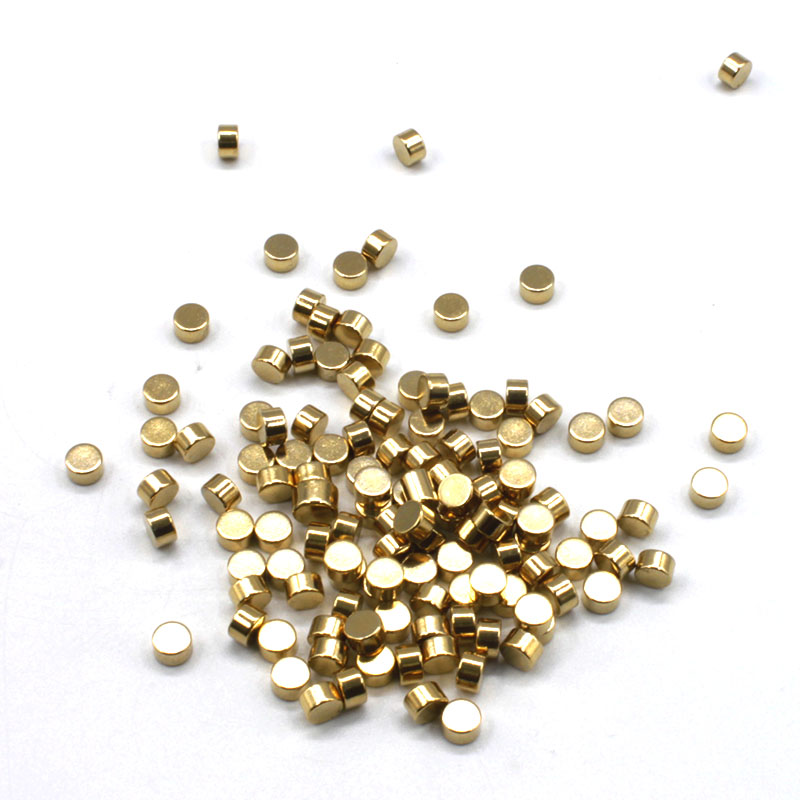

low price Gold Plated Disc Rare-Earth NdFeB Magnet

Specification:

Material Neodymium-Iron-Boron

Performance: Grade N45

Shape: disc, round, circle

Surface Gold: (can build all kinds of coatings)

45 MGOe(N45)Neodymium Rare Earth

Quadrapolar, HEXAPOLAR, OCTAPOLAR, CONCENTRIC, BIPOLAR

Penetration=4mm/0.16”

Magnet Width=4mm/0.16″

Magnet Thickness = 1.5 mm/0.06″

Pull Force = 2 N / 0.2 kgf/ 0.5 lbf

No Flux Plate attached

No plastic casing

Tolerance±0.05mm

Operating Temperature Maximum 80°C(can be customized temperature)

Engineering Service:

As custom magnet manufacturers, engineering is at the heart of

our business

Valued Service:

Internation exhibitions every year in USA and Germany for visiting

and meeting -

cheap Black Epoxy Coated Round Disc NIB Nd-Fe-B Magnets

Black Epoxy Coated Round Disc NIB Nd-Fe-B Magnets Parameter:

Material Grade N48

Plating/Coating:

Black epoxy coating

Specification:

D28 x 3 mm

Magnetism Direction:

Axial

Shape:

round, disc

Telerance:

+0.05mm to +0.1mm

Max working Temp:

≤80°C

Used widely use in toys, hardware, electronics, motors,instruments, medical instruments and other applications Packing Polybag Packing →Box Packing → Sealed Carton→Plywood Case/Plywoo Pallet -

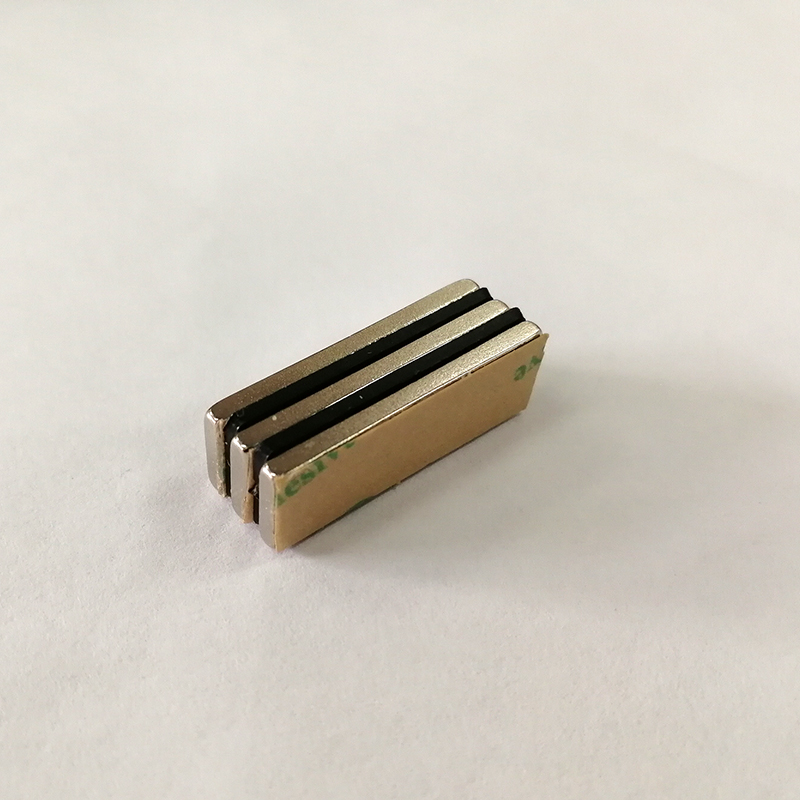

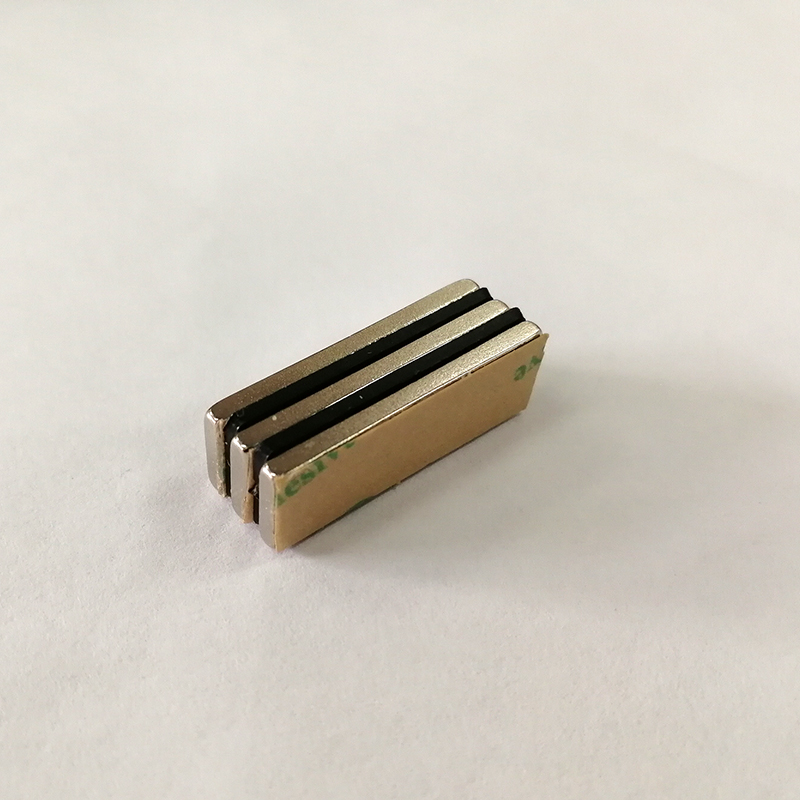

Block Magnets for Magnetic Bead Separation Stand in stock

Shape:

Customized (Block, Disc, Cylinder, Bar, Ring, Countersunk,Segment, Hook,Trapezoid, irregular shapes, etc)

Performance:

N52/Customized (N33 N35 N38 N40 N42 N45 N48 N50 N52……)

Coating:

Ni-Cu-Ni,Nickel Customized(Zn,Ni-Cu-Ni,Ni,Gold,Silver,Copper.Epoxy,Chrome,etc)

Magnetization:

Thickness Magnetized, Axially Magnetized,Diametrally Magnetized, Multi-poles magnetized,Radial Magnetized.(Customzied specific requirements magnetized)

Grade: Max. Operating Temperatures:

N35-N525 80℃(176°F)

N30M-N52M 100℃(212°F)

N30H-N52H 120℃(248°F)

N30SH-N52SH 150℃(302°F)

N28UH-N45UH 180℃(356°F)

N28EH-N42EH 200℃(392°F)

N30AH-N38AH 240℃(472°F) -

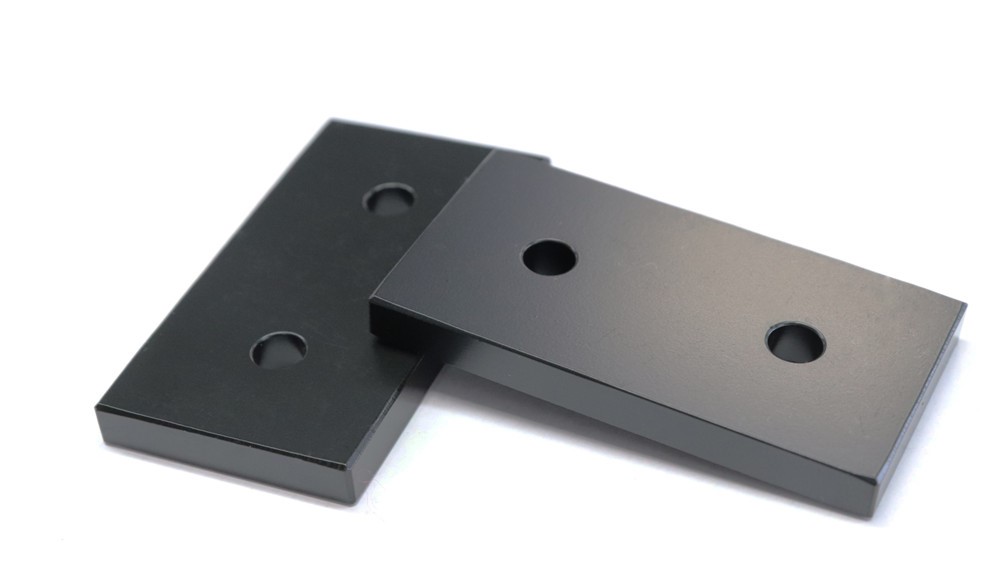

China magnetic material block suppliers

The magnetic material block is incredibly versatile and easy to use. It’s designed to work with a wide range of materials, including wood, plastic, metal, and more. Simply attach the block to your chosen surface and watch as it forms a strong and stable bond.

-

Single-side strong magnetic halbach array magnet

Halbach array magnets are a type of magnetic assembly that provides a strong and focused magnetic field. These magnets consist of a series of permanent magnets that are arranged in a specific pattern to generate a unidirectional magnetic field with a high degree of homogeneity.

-

Super Strong Rubber Flexible Magnetic Sheet Roll

- Type: Flexible Magnet

- Composite: Rubber Magnet

- Shape: Sheet / Roll

- Application: Industrial Magnet

- Dimension: Customized Magnet Size

- Material: Soft Ferrite Rubber Magnet

- UV: Gloss / matt

- Laminated: Self adhesive / PVC / art paper / PP / PET or as your requirement

-

High Quality Multipole Radial bonded neodymium ring magnet

NdFeB bonded compression magnets are a type of magnet that is made by compressing and bonding NdFeB magnetic powder with a polymer binder. Unlike traditional NdFeB magnets, which are made from a sintering process, bonded magnets can be formed into complex shapes and sizes, making them ideal for a wide range of applications.

-

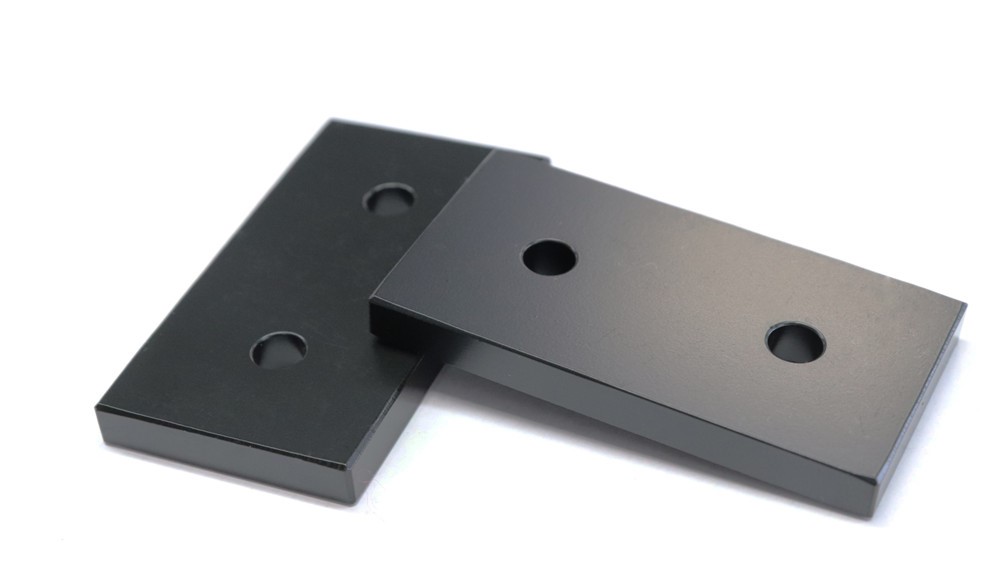

Customized NdFeB bonded compression magnets with holes

NdFeB bonded compression magnets are a useful magnet option for a variety of applications. Their ability to be produced in complex shapes and sizes, resistance to corrosion and demagnetization, and flexibility in magnetization direction make them a versatile and reliable choice. However, their lower magnetic energy product and higher production cost may make them less suitable for certain applications.

-

Customized NdFeB bonded compression magnets for Motors and generators

NdFeB bonded compression magnets are widely used in various applications, including motors and generators. These magnets are made by compressing a mixture of NdFeB powder and a high-performance polymer binder under high pressure, resulting in a strong, compact, and efficient magnet with excellent magnetic properties and dimensional stability.

-

Customized ring NdFeB bonded compression magnets for bearings

Ring NdFeB bonded compression magnets are an essential component in various industries, including aerospace, automotive, medical, and energy. These magnets offer exceptional performance in demanding applications, providing high magnetic strength, energy product, and superior dimensional stability. They are available in various sizes and shapes, including cylindrical, annular, and multi-pole ring magnets, providing designers and engineers with flexibility and versatility to create customized solutions for their applications.

-

High-Performance Injection Bonded Ferrite Magnets

Injection-molded ferrite magnets are a type of permanent ferrite magnet that is manufactured through the injection molding process. These magnets are created using a combination of ferrite powders and resin binders, such as PA6, PA12, or PPS, which are then injected into a mold to form a finished magnet with complex shapes and precise dimensions.