Alnico Magnets possess a hard and brittle nature, making them prone to chipping and cracking. To machine this material, specialized machining techniques are necessary. Magnetizing fields of approximately 3kOe (kilo Oersted) are required for Alnico magnets. Due to their relatively low coercivities, precautions must be taken to avoid adverse repelling fields that could result in partial demagnetization. It is advisable to store magnetized magnets with "keepers" to minimize the risk of partial demagnetization. In case of partial demagnetization, Alnico magnets can be easily re-magnetized. Cast Alnico allows for the creation of intricate and complex shapes, which is not feasible with other magnetic materials. An example of this is an Alnico rotor with a protected steel sleeve and epoxy potting. Alnico magnets are primarily composed of aluminum, nickel, cobalt, copper, iron, and sometimes titanium. Among the range of magnetic materials available, Alnico magnets exhibit high magnetic flux density, corrosion resistance, and excellent temperature stability, with a maximum working temperature of 600℃. Alnico magnets find wide applications in sensors, meters, electronics, instruments, medical devices, educational tools, automotive, aviation, and various other fields.

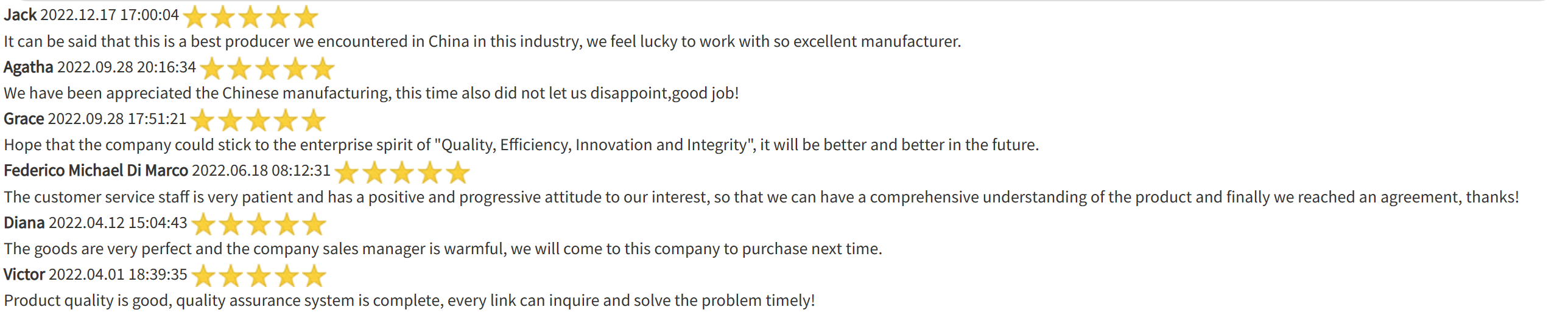

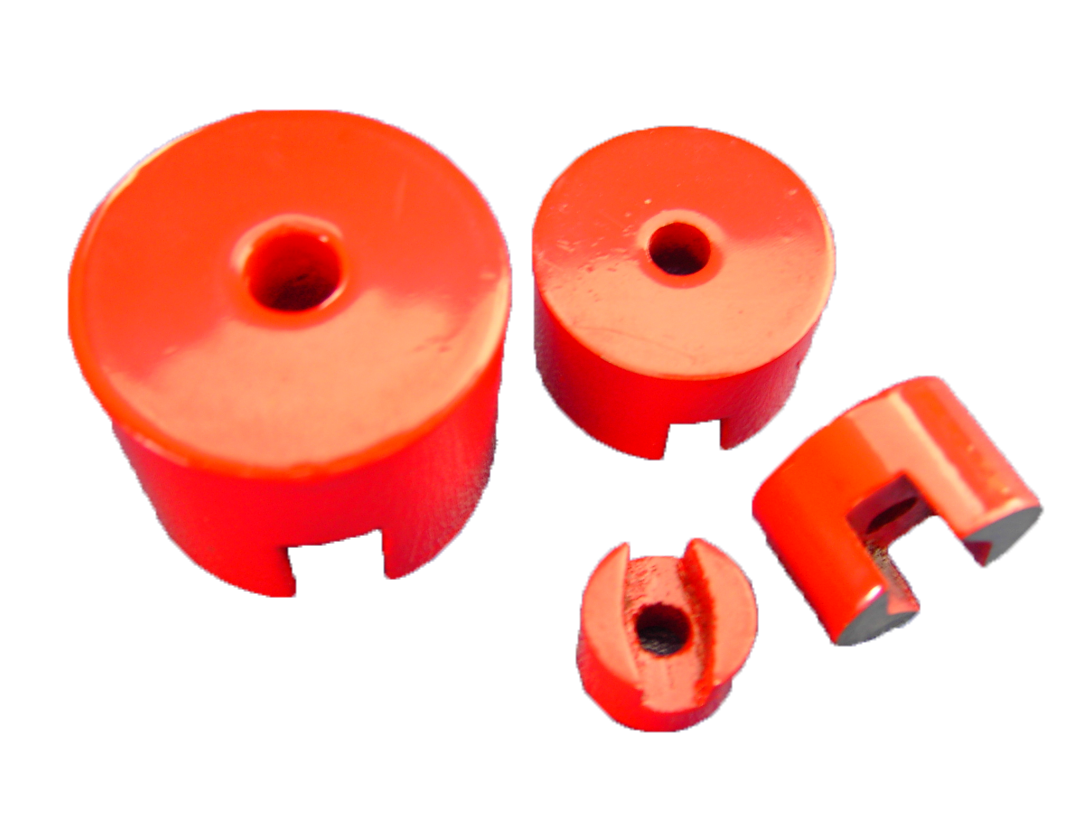

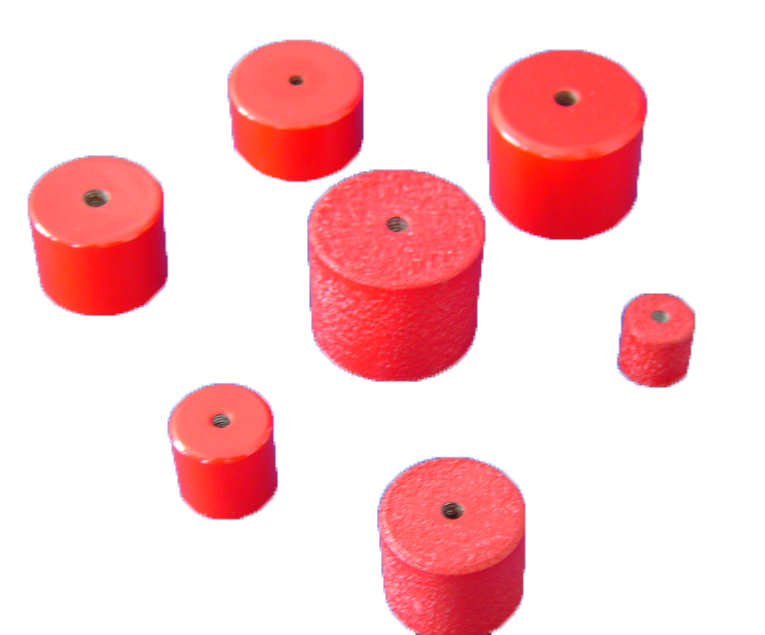

The magnetic cores of deep pot magnets are made of neodymium (NdFeB), samarium-cobalt (SmCo), or Alnico (AlNiCo), which is an alloy of aluminum, iron, copper, nickel, and cobalt. The choice of material affects the adhesive force and temperature resistance of the magnets.

Neodymium magnets are known for their exceptional strength.

Alnico magnets have a good adhesive force but cannot match the strength of neodymium pot magnets.

Samarium cobalt systems fall in between these two magnet systems in terms of their power development.

However, when it comes to temperature resistance, the situation is reversed. Alnico systems can endure the highest levels of heat, while neodymium systems generate the least amount of heat.

The magnets have the following maximum operating temperatures:

NdFeB 80°C / SmCo 250°C / AlNiCo 450°C.

With a history of more than ten years, Honsen Magnetics is a pioneer in the production and distribution of permanent magnets, magnetic components and magnetic goods. Our skilled team has a decade of expertise overseeing an integrated production process covering machining, assembly, welding and injection molding. This solid foundation enables us to offer a wide range of products, which have gained attention in the European and American markets. Our unwavering commitment to superior quality and affordable prices has strengthened our position as a reliable partner, fostering lasting relationships and a large satisfied client base. Honsen Magnetics isn't just about magnets; it's about magnets. It's about changing industries and shaping magnetic excellence.

- More than 10 years experiences in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a strong R&D team can provide perfect OEM&ODM service

- With 2 production plants, 3000 tons/year for magnets and 4mil pcs/month for magnetic products

- FEA simulation to calculate and optimize magnetic circuits

- Have the certificate of ISO 9001, IATF 16949, ISO14001, ISO45001, REACH and RoHs

- We only export qualified products to customers -

- Fast shipping & worldwide delivery

- Offer all kinds of payment methods

Our focus remains steadfast in providing our valued customers with avant-garde support and cutting-edge, competitive products that expand our market presence. Driven by revolutionary advances in permanent magnets and components, we are committed to driving growth and penetrating untapped markets through technological breakthroughs. Led by a chief engineer, our skilled R&D department leverages in-house capabilities, cultivates customer contacts, and anticipates changing market dynamics. Self-governing teams diligently oversee undertakings across the globe, ensuring that our research enterprise progresses steadily.

Quality management is the cornerstone of our organizational spirit. We firmly believe that quality is the vitality and guiding light of an enterprise. Beyond mere documentation, our quality management system permeates our practice. This strategic integration ensures that our products consistently meet and exceed customer expectations, reflecting our unwavering commitment to excellence.

Honsen Magnetics embodies enduring brilliance, including customer satisfaction and a commitment to safety. Parallel to this pursuit is our dedication to the personal growth of our employees. By nurturing their journey, we promote the sustainable growth of our company.