Automotive

As automotive technology continues to advance at an unprecedented rate, Honsen Magnetics is a leading manufacturer of magnets specifically designed for automotive applications. With a strong commitment to innovation, quality and customer satisfaction, Honsen Magnetics has revolutionized the automotive industry by providing reliable, efficient and high-performance magnets that enhance every aspect of automotive systems. Honsen Magnetics' range of automotive magnets are engineered to withstand the harshest conditions and provide exceptional performance. These magnets are used in a variety of automotive applications, from electric drivetrains to power steering systems, providing essential functionality and reliability. The car magnets offered by Honsen Magnetics are meticulously crafted using the highest quality materials and state-of-the-art manufacturing processes. These magnets have superior magnetic properties to ensure optimum efficiency and durability. Additionally, they are designed to withstand extreme temperatures, vibrations and other challenging conditions commonly found in the automotive industry. As a trusted and reputable magnet supplier, Honsen Magnetics prides itself on its dedication to customer satisfaction. The company's experienced team of engineers and technicians work closely with automakers to understand their specific requirements and develop custom magnet solutions that meet their unique needs.-

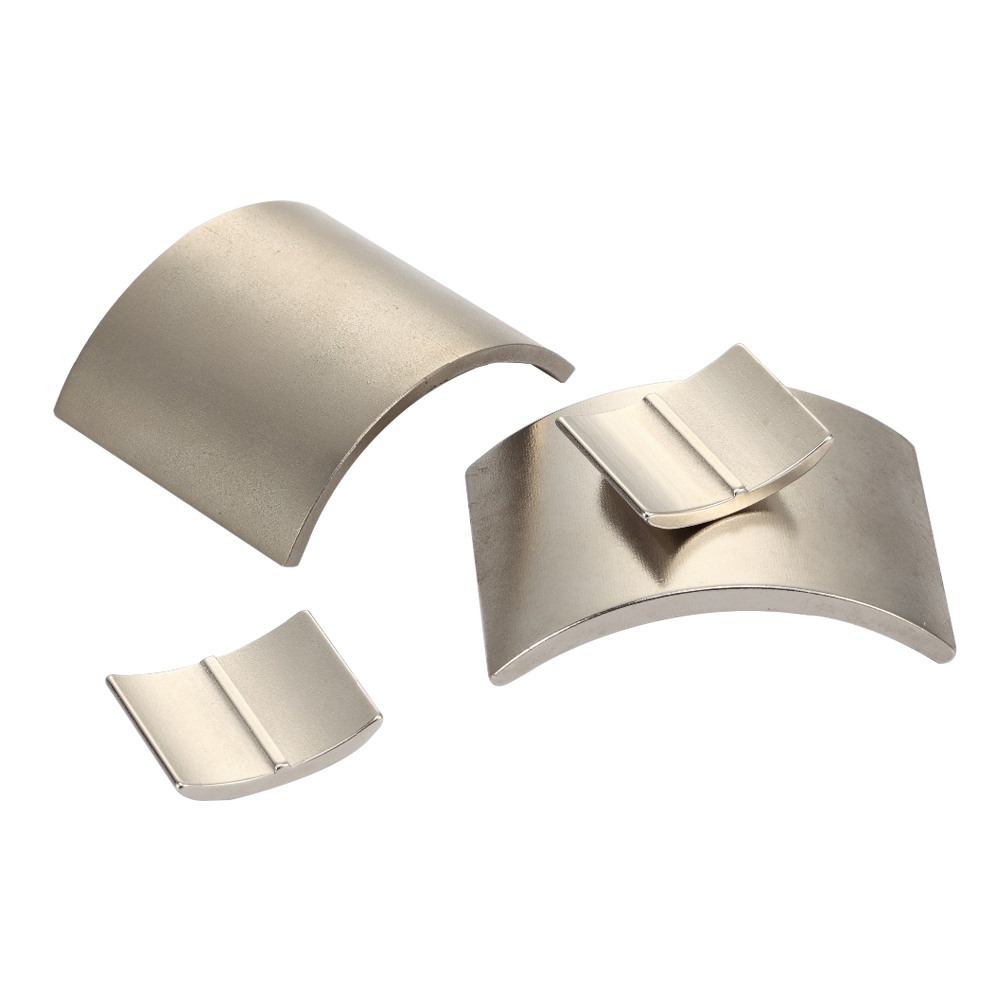

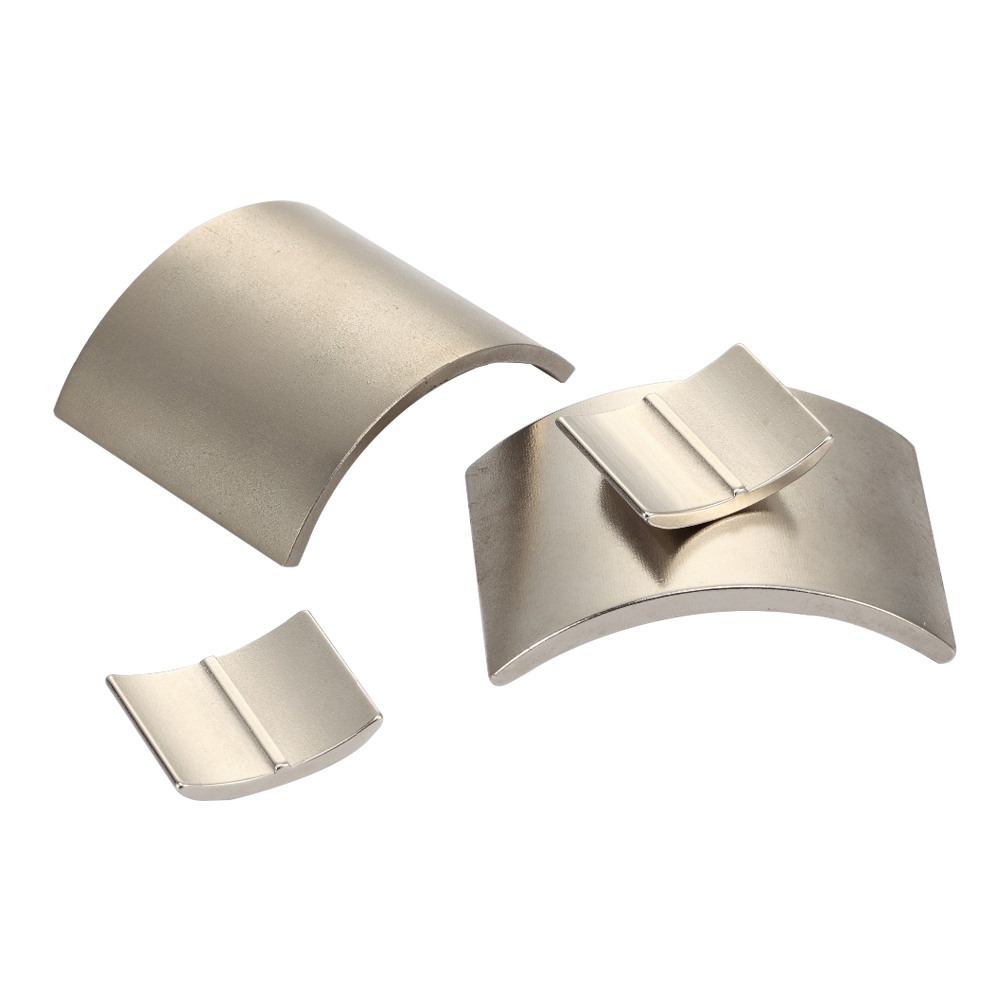

Neodymium (Rare Earth) Arc/Segment Magnet for Motors

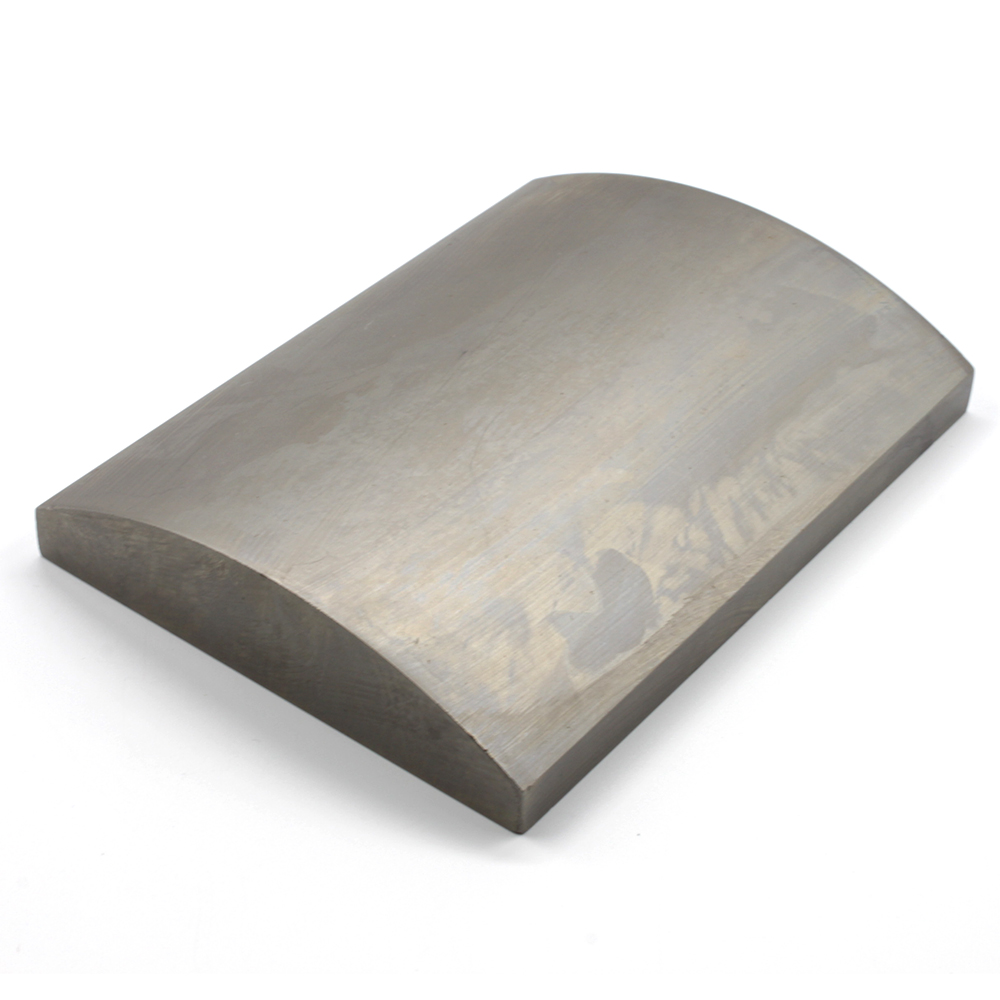

Product Name: Neodymium Arc/Segment/Tile Magnet

Material: Neodymium Iron Boron

Dimension: Customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Magnetization Direction: As per your request

-

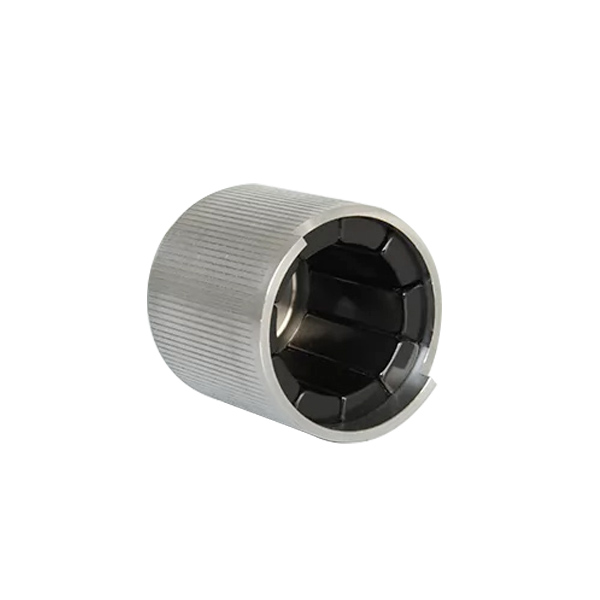

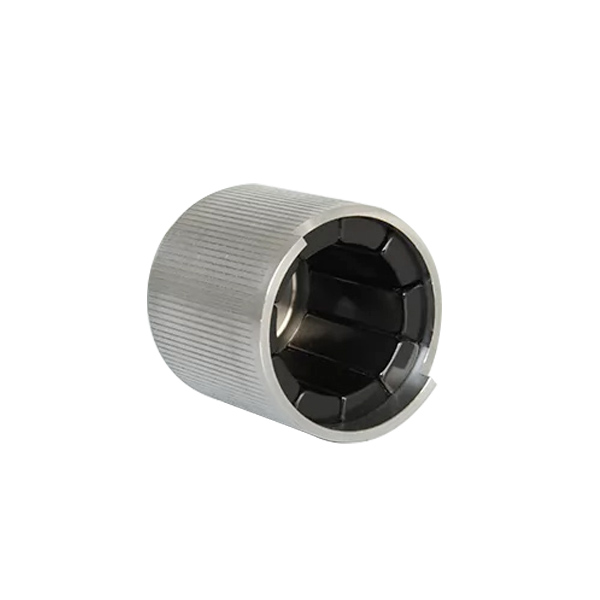

Magnetic Rotor Assemblies for High-Speed Electric Motors

Magnetic rotor, or permanent magnet rotor is the non stationary part of a motor. The rotor is the moving part in an electric motor, generator and more. Magnetic rotors are designed with multiple poles. Each pole alternates in polarity (north & south). Opposite poles rotate about a central point or axis (basically, a shaft is located in the middle). This is the principal design for rotors. Rare-earth permanent magnetic motor has a series of advantages, such as small size, light weight, high efficiency and good characteristics. Its applications are very extensive and extend all over fields of aviation, space, defense, equipment manufacturing, industrial and agricultural production and daily life.

-

Permanent Magnetic Couplings for Drive Pump & magnetic mixers

Magnetic couplings are non-contact couplings that use a magnetic field to transfer torque, force or movement from one rotating member to another. The transfer takes place through a non-magnetic containment barrier without any physical connection. The couplings are opposing pairs of discs or rotors embedded with magnets.

-

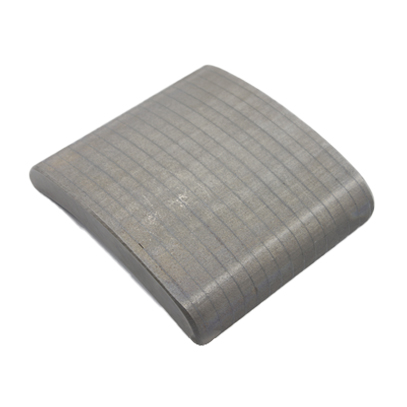

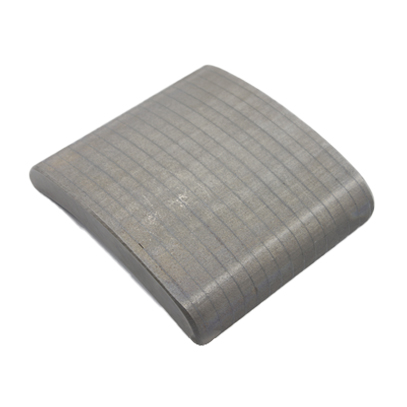

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

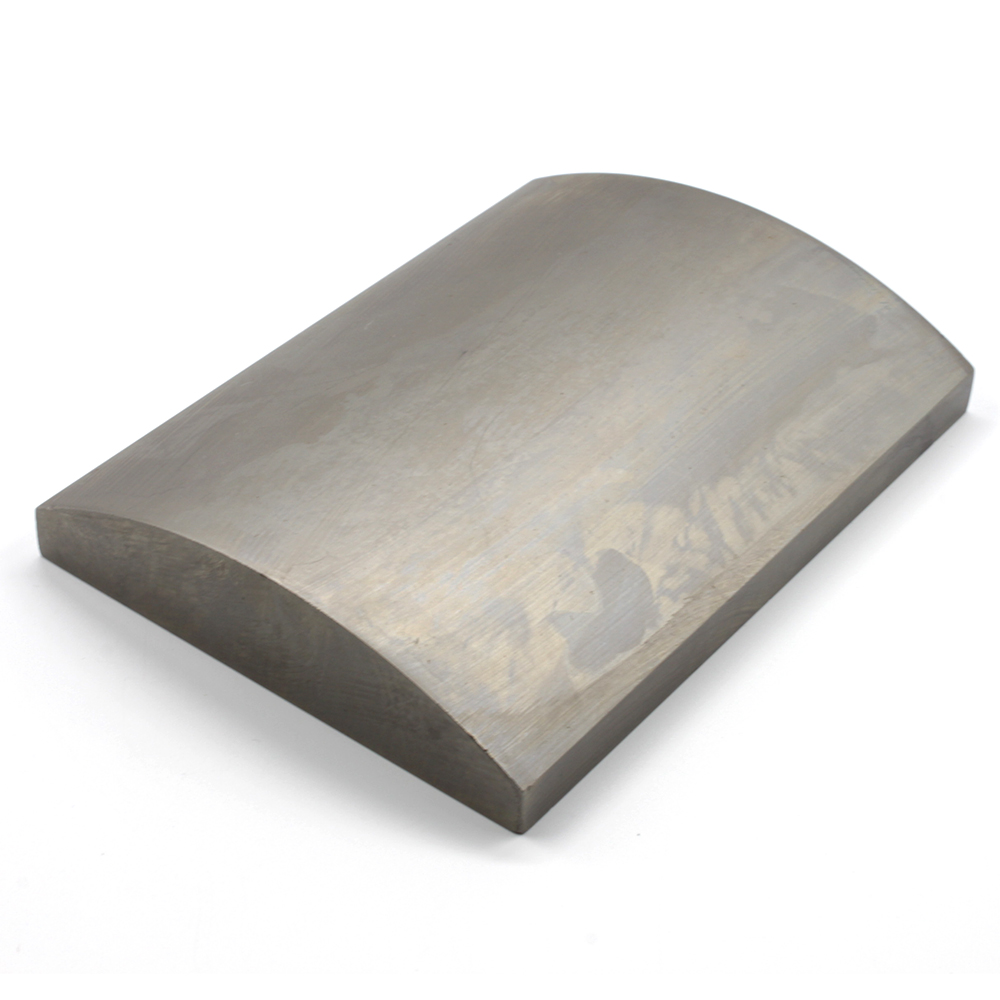

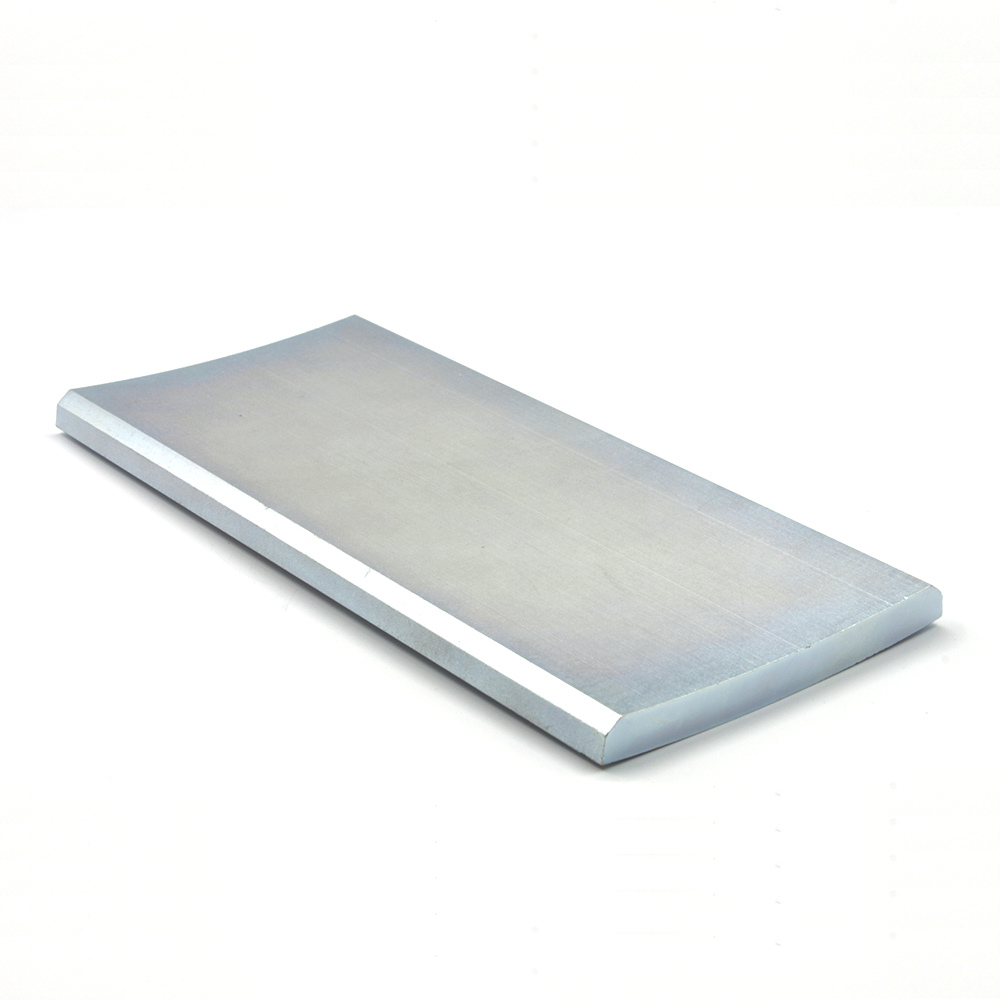

N38H Neodymium Magnets for Linear Motors

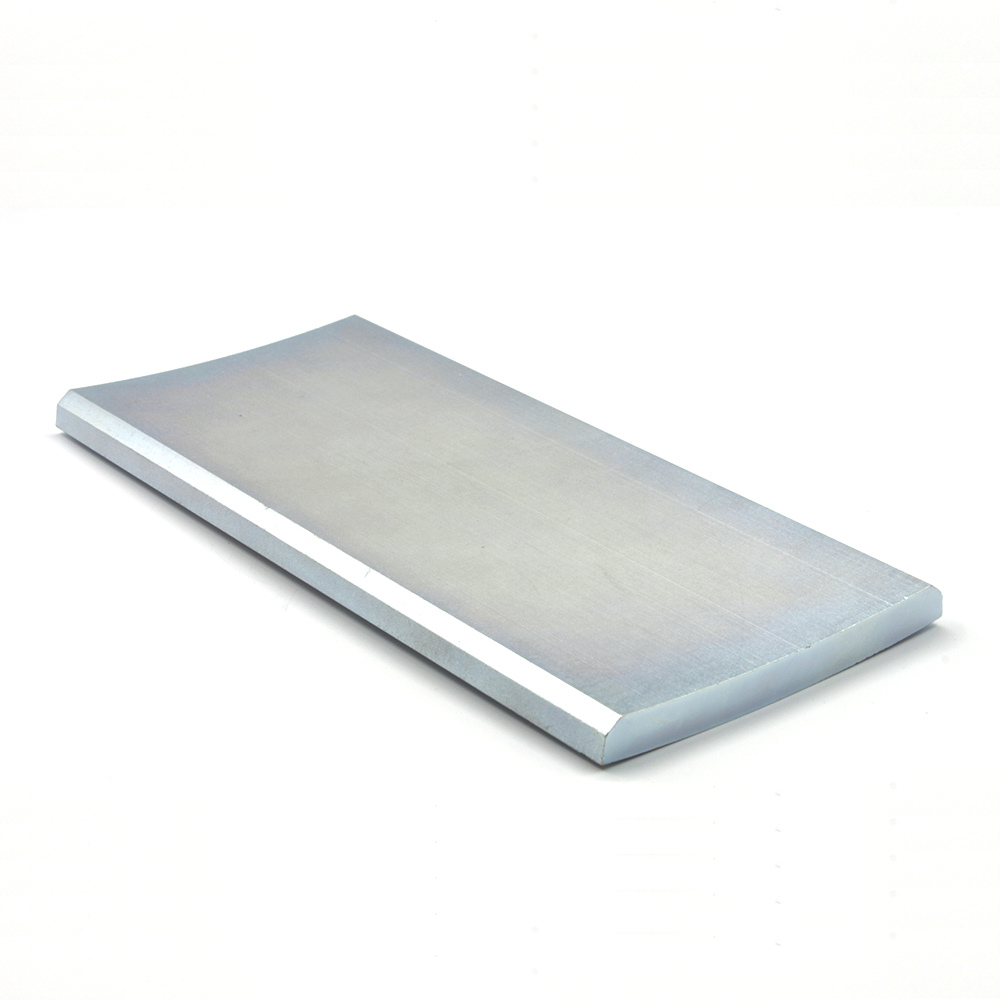

Product Name: Linear Motor Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium block magnet or customized -

Halbach Array Magnetic System

Halbach array is a magnet structure, which is an approximate ideal structure in engineering. The goal is to generate the strongest magnetic field with the smallest number of magnets. In 1979, when Klaus Halbach, an American scholar, conducted electron acceleration experiments, he found this special permanent magnet structure, gradually improved this structure, and finally formed the so-called “Halbach” magnet.

-

Magnetic Motor Assemblies with Permanent Magnets

Permanent magnet motor generally can be classified into permanent magnet alternating current (PMAC) motor and permanent magnet direct current (PMDC) motor according to current form. PMDC motor and PMAC motor can be further divided to brush/brushless motor and asynchronous/synchronous motor, respectively. Permanent magnet excitation can significantly decrease power consumption and strengthen the running performance of the motor.

-

Permanent Magnets used in Automotive Industry

There are many different uses for permanent magnets in automotive applications, including efficiency. The automotive industry is focused on two kinds of efficiency: fuel-efficiency and efficiency on the production line. Magnets help with both.

-

Servo Motor Magnets Manufacturer

The N pole and S pole of the magnet are arranged alternately. One N pole and one s pole are called a pair of poles, and the motors can have any pair of poles. Magnets are used including aluminum nickel cobalt permanent magnets, ferrite permanent magnets and rare earth permanent magnets (including samarium cobalt permanent magnets and neodymium iron boron permanent magnets). The magnetization direction is divided into parallel magnetization and radial magnetization.

-

Wind Power Generation Magnets

Wind energy has become one of the most feasible clean energy sources on earth. For many years, most of our electricity came from coal, oil and other fossil fuels. However, creating energy from these resources causes serious damages to our environment and pollute the air, land and water. This recognition has made many people to turn to green energy as a solution.

-

Neodymium (Rare Earth) Magnets for Efficient Motors

A neodymium magnet with a low degree of coercivity may begin to lose strength if heated to more than 80°C. High coercivity neodymium magnets have been developed to operate at temperatures up to 220°C, with little irreversible loss. The need for a low temperature coefficient in neodymium magnet applications has led to the development of several grades to meet specific operational requirements.

-

Permanent Magnets for MRI & NMR

The large and important component of MRI & NMR is magnet. The unit that identifies this magnet grade is called Tesla. Another common unit of measurement applied to magnets is Gauss (1 Tesla = 10000 Gauss). At present, the magnets used for magnetic resonance imaging are in the range of 0.5 Tesla to 2.0 Tesla, that is, 5000 to 20000 Gauss.