For more than a decade, Honsen Magnetics have been helping industry experts choose and utilize Alnico Magnets in the right way. Honsen Magnetics provides off-the-shelf and custom-made Alnico Magnets, from prototype to production.

The primary components of Alnico Magnets are Aluminum-Nickel-Cobalt. These magnets are known for their great heat resistance and temperature stability, along with hard and brittle characteristics. Forms of Alnico Magnets available from us include Bars, Rods, Rails, Side Pole Rotors, Rotors, and Horseshoe Magnets. Cutting, grinding, EDM, fabrication, and assembly services to your specific requirements and tolerances can be supplied upon request.

Alnico Magnets are perfect for applications. Made from aluminum, nickel and cobalt, they are ideal for holding and sensing assemblies. They can be supplied in shorter lengths, and for best results, Alnico lengths should be at least five times the diameter of the cross-section.

Features:

Fantastic corrosion resistance

High heat resistance & temperature stability

High working temperature

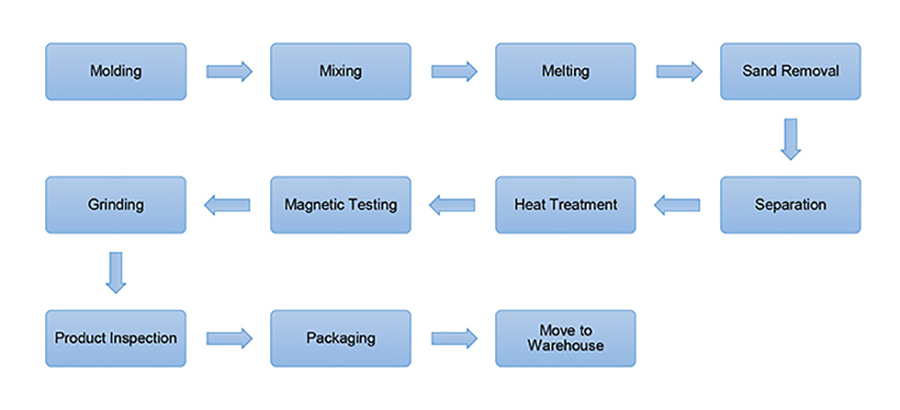

Manufacturing Process of Cast AlniCo Magnets

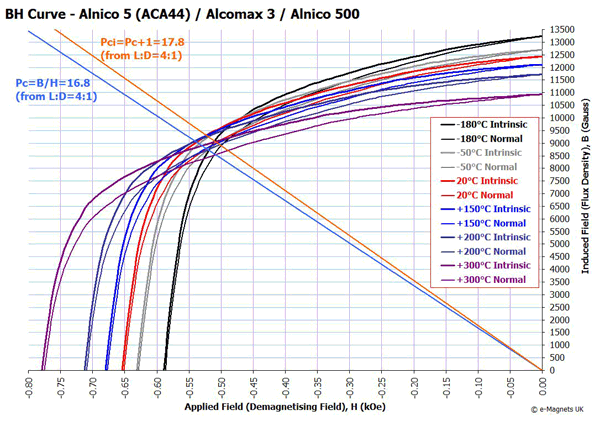

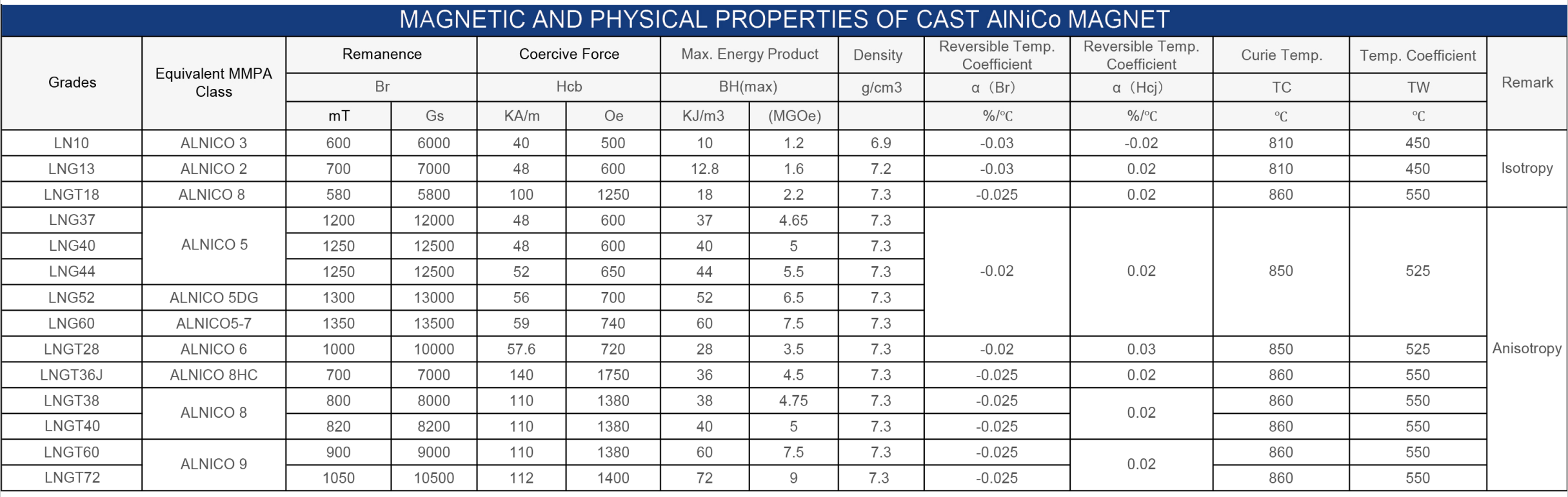

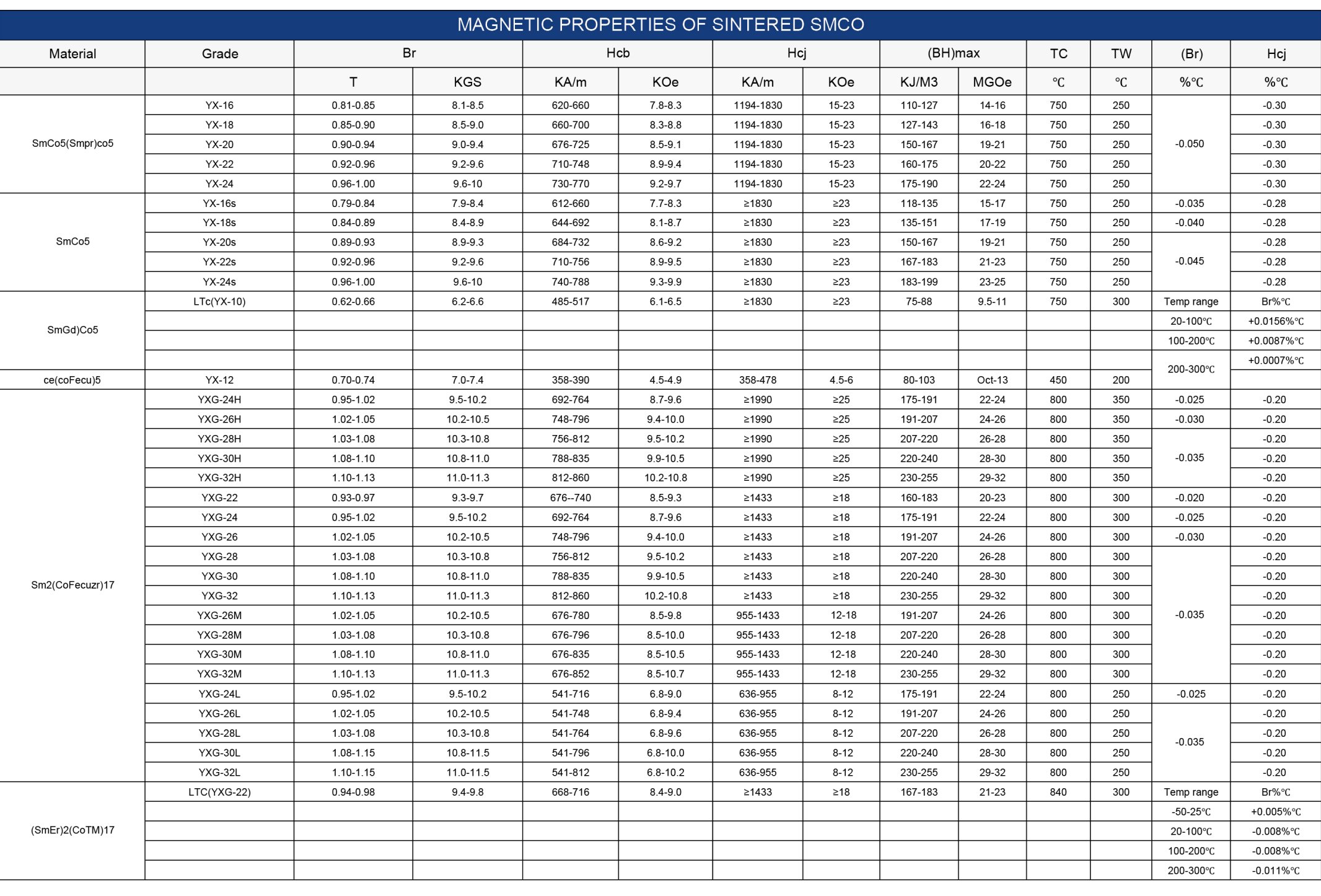

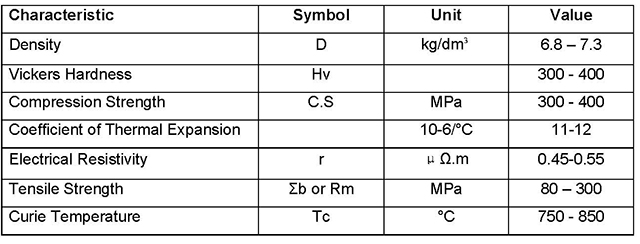

Alnico magnets are renowned for their high remanence, low coercitivity, and temperature stability. The properties for each grade at room temperature are listed in Tables 1 and 2. Furthermore, additional information such as demagnetization curves for different temperatures is available for download in the datasheets. Table 3 outlines the general characteristics of Alnico magnets. Figure 2 illustrates the temperature stability, depicting the demagnetization curves of Alnico 5 grade from -180 C to +300 C. This figure demonstrates how the output of the magnet remains constant when the working point is near BHmax over a large temperature range.

Table 1: Typical magnetic properties of cast Alnico magnet

Table 2: Typical magnetic properties of sintered Alnico magnet

The physical properties of Alnico magnets are presented in Table 3. It should be noted that these values should not be considered as guaranteed, as they are not monitored during the manufacturing process.

Table 3:Physical Properties of Alnico magnets

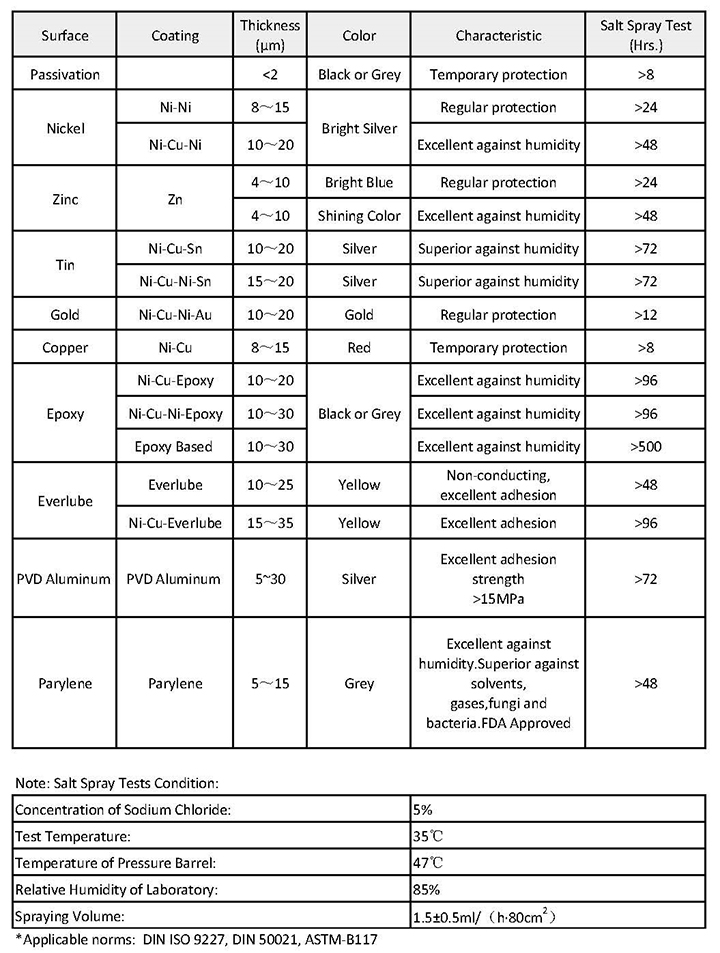

Surface Treatment:

Alnico magnets typically do not need any protection from corrosion and can be used without a coating. However, some applications may require a smooth surface, and in these cases, a protective coating can be applied.

Notes:

The corrosion resistance of these coverings fluctuates depending on the form of magnets, such as chamfers and inner rings, in diverse surroundings.

Why Honsen Magnetics

Our complete production line guarantees production capacity from raw materials to finished products

We serve ONE-STOP-SOLUTION to ensure customers efficient and cost-effective purchasing.

We test each piece of magnets to avoid any quality problem for customers.

We offer different types of packaging for customers to keep products & transportation safe.

We work with big customers as well as small ones without MOQ.

We offer all kinds of payment methods to facilitate customers' purchasing habits.