As the first commercially viable rare-earth permanent magnet material, samarium cobalt (SmCo) is considered the first choice for many high-performance applications.

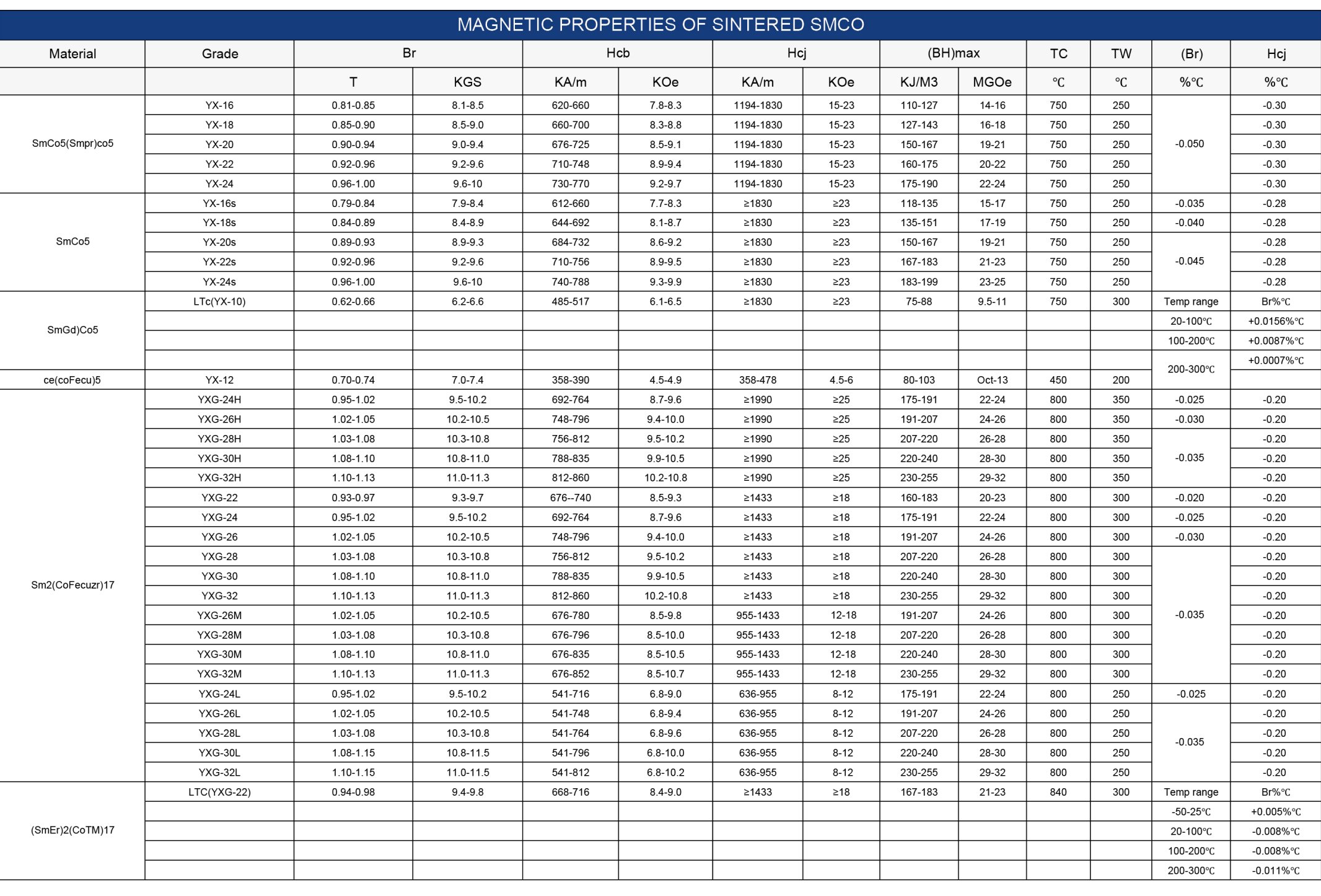

Developed in the 1960s, it revolutionized the industry by tripling the energy production of other materials available at the time. The energy product of samarium cobalt magnets ranges from 16MGOe to 33MGOe. Its excellent resistance to demagnetization and excellent thermal stability make it ideal for demanding motor applications.

SmCo magnets are also significantly more corrosion-resistant than NdFeB magnets, but coating treatments are still recommended when exposed to acidic conditions. This corrosion resistance makes them popular in medical applications. Although SmCo magnets have similar magnetic properties to NdFeB magnets, their commercial success has been limited due to the high cost and strategic value of cobalt.

As a rare earth magnet, samarium cobalt is an intermetallic compound of samarium (rare earth metal) and cobalt (transition metal). The production process includes milling, pressing, and sintering in an inert atmosphere. The magnets are then pressed using an oil bath (isostatic pressing) or a die (axial or diametral).

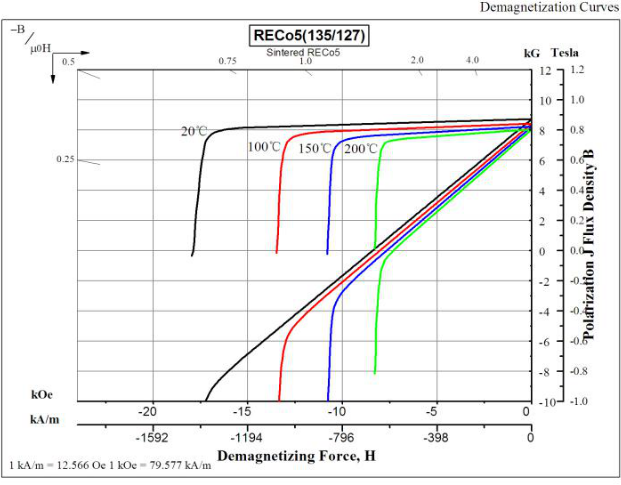

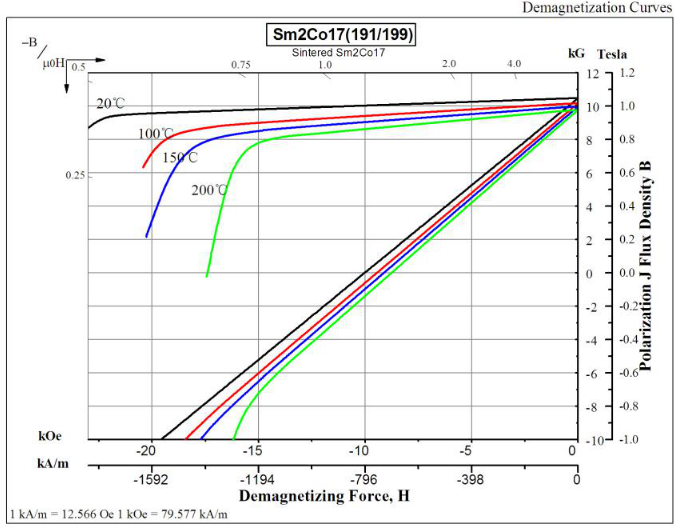

Samarium cobalt is produced by grinding with diamond tools. These magnets have high magnetic properties, the maximum energy product is about 240KJ/m3. They are available in two grades: Sm1Co5 and Sm2Co17, each with unique magnetic behavior (Sm1Co5 nucleation, Sm2Co17 pinning). Sm2Co17 exhibits the highest magnetic properties but is more difficult to magnetize (requires 4000kA/m) than Sm1Co5 (requires 2000kA/m).

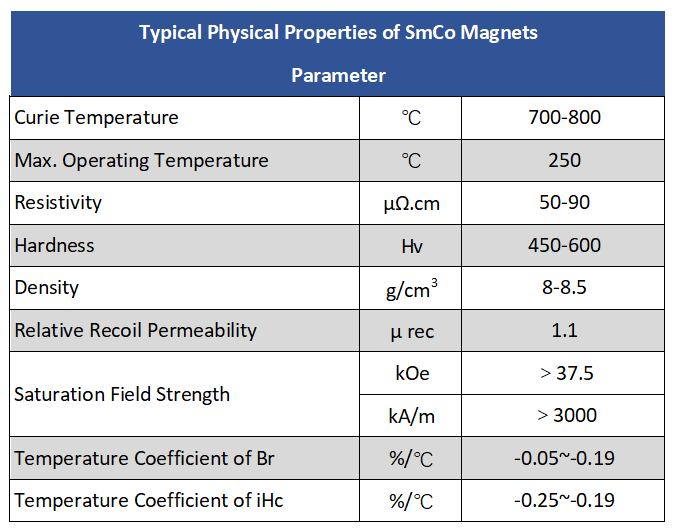

The advantages of SmCo magnets are corrosion resistance and good thermal performance compared to NdFeB magnets. The Curie temperature of Sm1Co5 is about 750°C, while that of Sm2Co17 is about 850°C. In addition, the decrease in magnetic properties with increasing temperature is relatively low. Samarium Cobalt magnets are highly valued in the military, aerospace and electro-medical industries, especially when oxidation or thermal requirements are critical. They found similar applications for NdFeB magnets, including sensors, speakers, electric motors, instruments and switches.

Samarium Cobalt is the most expensive permanent magnet material. However, its high-energy product has contributed to its commercial success by reducing the volume of magnet material required for a given task. Samarium cobalt magnets can typically operate at temperatures up to 350°C, although their actual performance at this temperature depends on the design of the magnetic circuit. As with all permanent magnetic materials, care must be taken when handling magnetized samples. Samarium cobalt magnets are prone to chipping and should not be used as structural parts in assemblies.

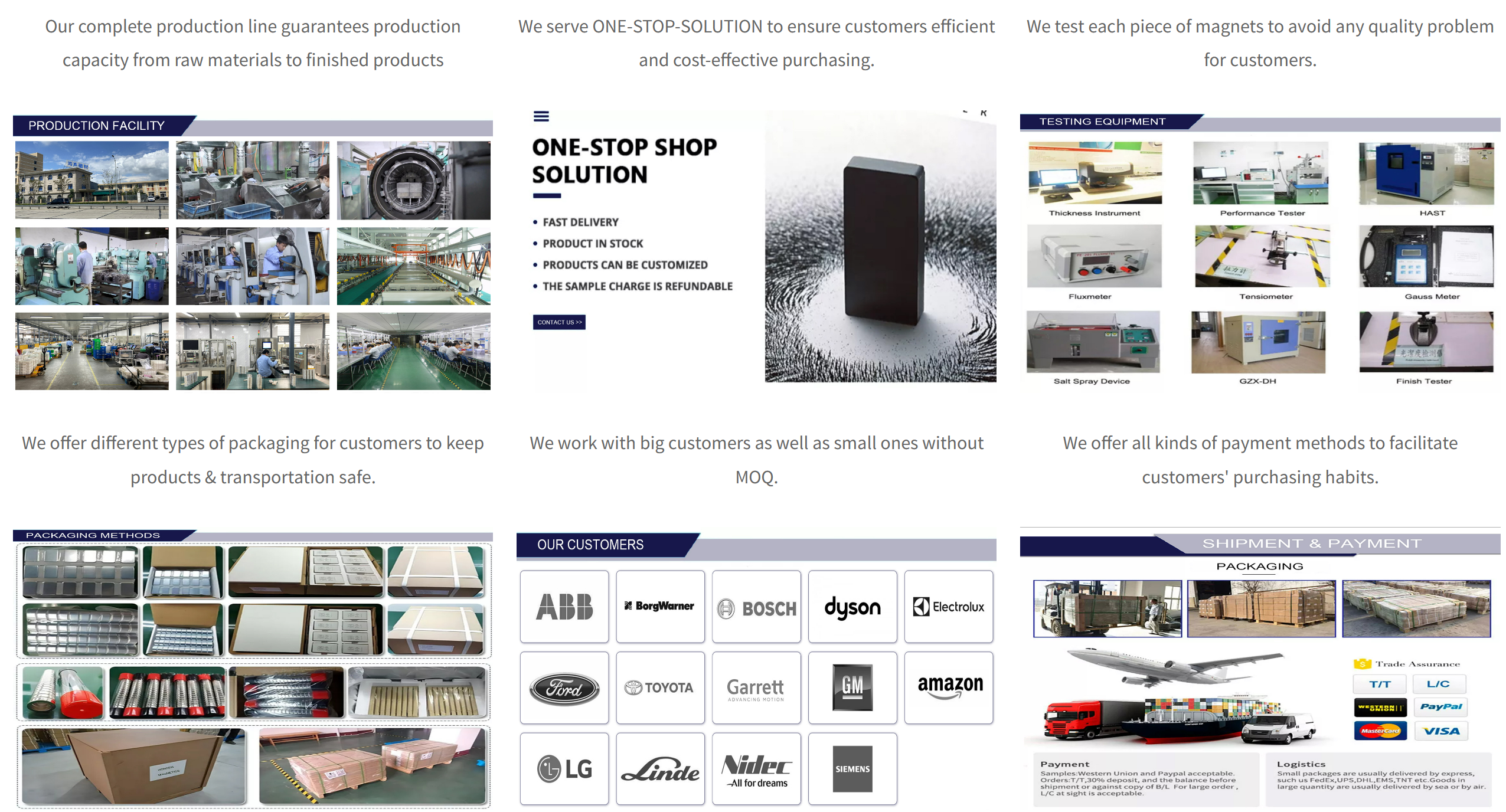

With a rich history of more than ten years, Honsen Magnetics is a beacon of excellence in the field of permanent magnets, magnetic components and magnetic products. Our skilled team has carefully planned a comprehensive production line including machining, assembly, welding and injection molding. Praised for their superior quality and cost-effectiveness, our products have made significant progress in European and American markets. Driven by a client-centric approach, our services create lasting partnerships, resulting in a large and satisfied client base. Honsen Magnetics is your trusted partner for magnetic solutions embodying precision and innovation.

Our company's goal is to provide customers with visionary support and cutting-edge, competitive products, thereby enhancing our market position. Driven by unparalleled breakthroughs in permanent magnets and components, we are committed to growth and expansion into new markets through continuous technological innovation. Our skilled R&D department, led by a chief engineer, leverages our in-house expertise, cultivates client relationships and anticipates market trends. Independent teams carefully manage global projects, ensuring that our research work continues to progress.

Quality management is the essence of our company fabrics. We see quality as the heartbeat and compass of our organization. Our dedication goes beyond mere paperwork - we intricately integrate our Quality Management System into our processes. Through this approach, we ensure our products consistently meet and exceed our customers' expectations, reflecting our commitment to excellence.

Empowerment and Warranty are at the heart of Honsen Magnetics' ethos. We offer both customer satisfaction and safety guarantees, reflecting our commitment to the growth of each team member. This symbiotic relationship drives us to achieve sustainable business development.