Magnetic Filter Bar

A magnetic filter bar is a tool commonly used to clean impurities from liquids and gases. This tool typically consists of one or more magnetic rods that capture and filter impurities in liquid or gas lines to protect equipment from damage.

Magnetic filter rods can filter liquids, gases, powders and solid materials very well. Whether it treats water, oil, fuel or starch, glass, minerals, etc., it can get good results.

Magnetic filter rods have good filtration efficiency. Due to its magnetic adsorption property, it can filter out tiny impurities effectively, thus improving the quality and purity of products.

Magnetic filter rods are easy to clean, maintain and replace. Due to its simple structure, it can be easily disassembled and cleaned to maintain good usage. If it needs to be replaced, simply replace the magnetic filter bar.

Magnetic filter rods are economical and practical. Compared to conventional filters, magnetic filter rods require no additional energy or cost and can perform filtration tasks quickly and efficiently, thus reducing production costs and increasing productivity.

Magnetic Filter Bar Specifications

Size: The size of magnetic filter rods should be selected according to the size of the pipeline and flow requirements. The size is usually described by parameters such as length and diameter.

| Item No. | Diameter (mm) |

Length (mm) |

Surface Flux (Gauss) |

Item No. | Diameter (mm) |

Length (mm) |

Surface Flux (Gauss) |

| 25×100 | 25 | 100 | 1500-14000GS | 25×600 | 25 | 600 | 1500-14000GS |

| 25×150 | 25 | 150 | 1500-14000GS | 25×650 | 25 | 650 | 1500-14000GS |

| 25×200 | 25 | 200 | 1500-14000GS | 25×700 | 25 | 700 | 1500-14000GS |

| 25×250 | 25 | 250 | 1500-14000GS | 25×750 | 25 | 750 | 1500-14000GS |

| 25×300 | 25 | 300 | 1500-14000GS | 25×800 | 25 | 800 | 1500-14000GS |

| 25×350 | 25 | 350 | 1500-14000GS | 25×850 | 25 | 850 | 1500-14000GS |

| 25×400 | 25 | 400 | 1500-14000GS | 25×900 | 25 | 900 | 1500-14000GS |

| 25×450 | 25 | 450 | 1500-14000GS | 25×950 | 25 | 950 | 1500-14000GS |

| 25×500 | 25 | 500 | 1500-14000GS | 25×1000 | 25 | 1000 | 1500-14000GS |

| 25×550 | 25 | 550 | 1500-14000GS | 25×1500 | 25 | 1500 | 1500-14000GS |

Temperature: The material and housing of a magnetic filter bar should be able to withstand the high or low temperatures of its application environment.

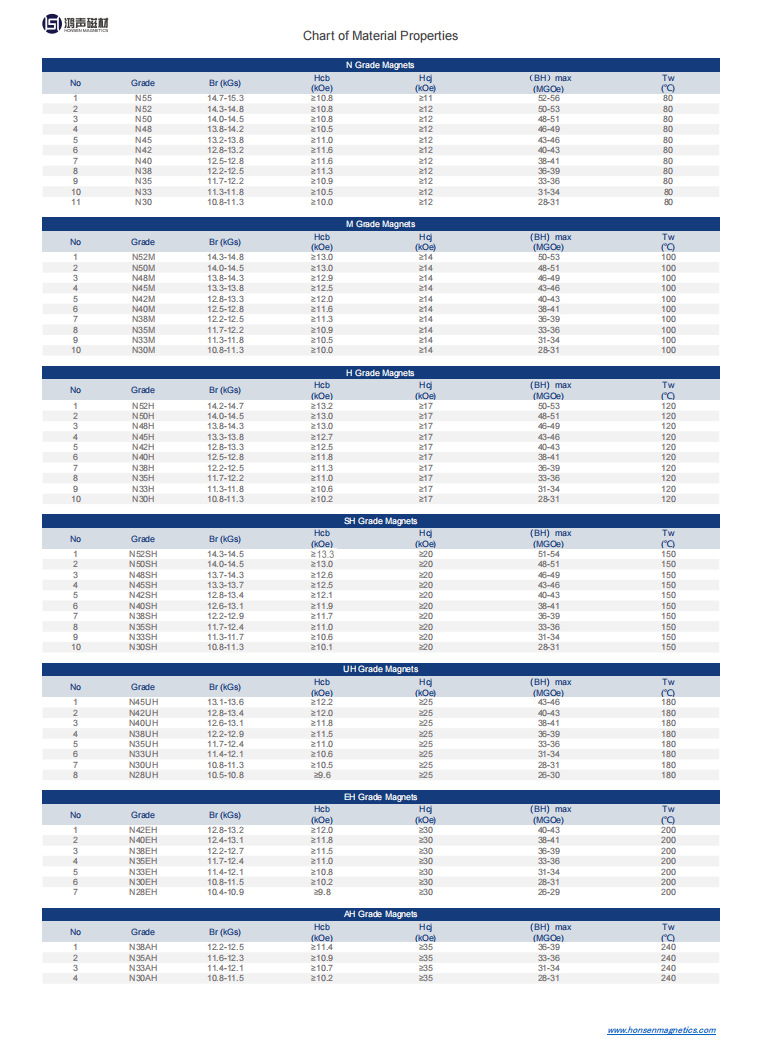

| Grade | Max. working Temp | Curie Temp | Supportable magnetic grade |

| N | 80℃/176℉ | 310℃/590℉ | N30-N55 |

| M | 100℃/212℉ | 340℃/644℉ | N30M-N52M |

| H | 120℃/248℉ | 340℃/644℉ | N30H-N52H |

| SH | 150℃/302℉ | 340℃/644℉ | N30SH-N52SH |

| UH | 180℃/356℉ | 350℃/662℉ | N28UH-N45UH |

| Eh | 200℃/392℉ | 350℃/662℉ | N28EH-N42EH |

| AH | 240℃/464℉ | 350℃/662℉ | N30AH-N38AH |

Curie Temp: also called Curie point or magnetic transition point, is the theoretical working temperature limit of magnetic materials, beyond the Curie temperature, the magnetic properties of magnetic materials will disappear completely.

Max.working Temp: If the maximum working temperature is exceeded, the magnetism of magnetic material will be demagnetized and irreversible loss will occur.

Relationship: the higher the Curie temperature, the higher the working temperature of the material, and the better the temperature stability.

Magnetic force: The magnetic force of a magnetic filter bar depends on the type and number of magnets inside it. A stronger magnetic force improves the filtration efficiency but may also affect the flow rate of the liquid or gas.

Material: The material of the magnetic filter rod should be compatible with the liquid or gas being filtered and should not be subject to corrosion.

Because of its excellent corrosion resistance, stainless steel is a commonly used material in many applications. However, for applications that require a higher level of corrosion resistance, it is equally important to choose a higher grade of stainless steel material. Examples include 316 or 316L, which are particularly suitable for industries such as food or chemical processing, where exposure to harsh chemicals or high humidity may occur.

If you are unsure which material is best for your specific application needs, please feel free to contact us. Our team of experts can provide you with advice and guidance to help you make an informed decision. At Honsen, we are committed to ensuring that you receive the best material for your application, and we are always here to help.

Installation:

End of the magnet has male threads

End of the magnet has female threads

Ends of the magnet are flat welded

Both ends of the magnet can be custom mounted to meet your specific requirements, with options such as male, female, and flat weld. Whatever your needs, we can provide the right magnet to ensure a seamless installation process.

How to properly select the right magnetic filter bar?

Flow rate: Determine the flow rate and operating temperature that needs to be filtered. This helps determine how many magnetic filter rods are needed and which type of magnetic filter rods.

Magnetic strength: Select the appropriate magnetic strength based on the type and size of impurities to be removed. Typically, stronger magnetic filter rods are required for larger particulate matter.

Shape: Select the appropriate magnetic filter bar shape according to the actual installation space and equipment requirements of the filter.

Material: Select suitable materials to suit different liquid media and environments, such as stainless steel, titanium alloy, permanent magnetic material, etc.

Life and maintenance cost: Select magnetic filter rods with long life and low maintenance cost to reduce usage cost and maintenance cost.

Application of magnetic filter bar

Plastic industry: Magnetic filter rods are often used in the cooling circulation system of injection molding machines, extruders, blow molding machines and other equipment to remove iron chips, iron powder and other impurities to protect the normal operation of the equipment.

Pharmaceutical industry: magnetic filter rods can remove impurities such as iron chips and steel spikes from liquid pharmaceuticals to ensure the purity and quality of drugs.

Food industry: Magnetic filter rods are widely used in food production lines to remove metal impurities in food to ensure the quality and safety of products.

Machining industry: Magnetic filter rods are often used in machine tool coolant to remove iron chips, sand and other impurities to extend tool life and improve machining accuracy.

Gas industry: Magnetic filter rods can remove iron chips and other impurities in natural gas and liquefied gas to protect the safe operation of gas equipment.

Chemical industry: It is used to remove ferromagnetic particles and oxides suspended in the solution.

Paper industry: used to remove ferromagnetic impurities in the papermaking process to ensure the quality of paper.

Mining industry: used to separate minerals containing iron from ore and improve the efficiency of mineral processing.

Water treatment industry: magnetic filter rods and bars are effective tools for removing iron, manganese and other metals from water, making it safe for drinking and other uses.

Textile industry: Magnetic filter rods and bars are used in textile manufacturing to remove metal contaminants from fabrics, ensuring product quality and preventing damage to machinery.

Automotive industry: Magnetic filter rods are used in automotive manufacturing to remove metal contaminants from coolant and lubricants to prevent damage to equipment and ensure product quality.

Our Advantages

Find the perfect round magnetic filter bar for your needs! Our magnetic rods are available upon custom request.

1.Our magnetic filter rods and bars are made from high quality stainless steel tubing and come with high performance neodymium magnets to suit your specific application. Using individual magnetic filter rods, you can build or modify your own magnetic separation equipment.

2.Choose the magnetic strength that best suits your needs! Our products are available in magnetic strengths from 1500-14000 gauss to meet your specific requirements. Bars equipped with strong neodymium magnets can have magnetic values up to 14,000 gauss on their surface.

3.A perfect fit for our fully sealed and welded rods! We offer customizable male, female or flat welded ends to meet your specific requirements.

4.All of our magnetic bars are waterproof, ensuring that they work effectively even in wet or humid environments.

5.Our magnetic filter bars and rods are well polished to provide a professional appearance and to ensure they are easy to clean and maintain.

With our quality materials and flexible options, you can confidently build or modify your own magnetic separation equipment.

Post time: Apr-13-2023