NdFeB Bonded Compressed Magnets

NdFeB bonded compressed magnets are made by combining NdFeB magnetic powder with a binder such as epoxy resin or nylon. This process allows for a range of complex shapes to be produced, which cannot be achieved with traditional sintered NdFeB magnets. The advantages of NdFeB bonded compressed magnets include their high magnetic strength, excellent temperature stability, and good resistance to demagnetization. They are also cost-effective and can be customized to meet specific requirements. Honsen Magnetics understands the different needs of customers, therefore, we offer various shapes and sizes to suit different applications. From small precision equipment to heavy machinery, our magnets are versatile enough to meet different needs. Our complete range of NdFeB bonded compression magnets includes block, disk, ring and custom shapes to customer specifications. Honsen Magnetics places great emphasis on quality, ensuring that our NdFeB bonded compression magnets undergo rigorous testing and stringent quality control measures. We take pride in supplying magnets that consistently meet and exceed industry standards.-

Customized ring-shaped NdFeB injection bonded magnets

Customized ring-shaped NdFeB injection bonded magnets are a type of high-performance magnet that is used in a variety of industrial and commercial applications. These magnets are made by injecting a mixture of NdFeB powder and a high-performance polymer binder into a mold under high pressure, resulting in a strong, compact and efficient magnet with excellent dimensional stability and superior magnetic properties.

-

High Quality Multipole Radial bonded neodymium ring magnet

NdFeB bonded compression magnets are a type of magnet that is made by compressing and bonding NdFeB magnetic powder with a polymer binder. Unlike traditional NdFeB magnets, which are made from a sintering process, bonded magnets can be formed into complex shapes and sizes, making them ideal for a wide range of applications.

-

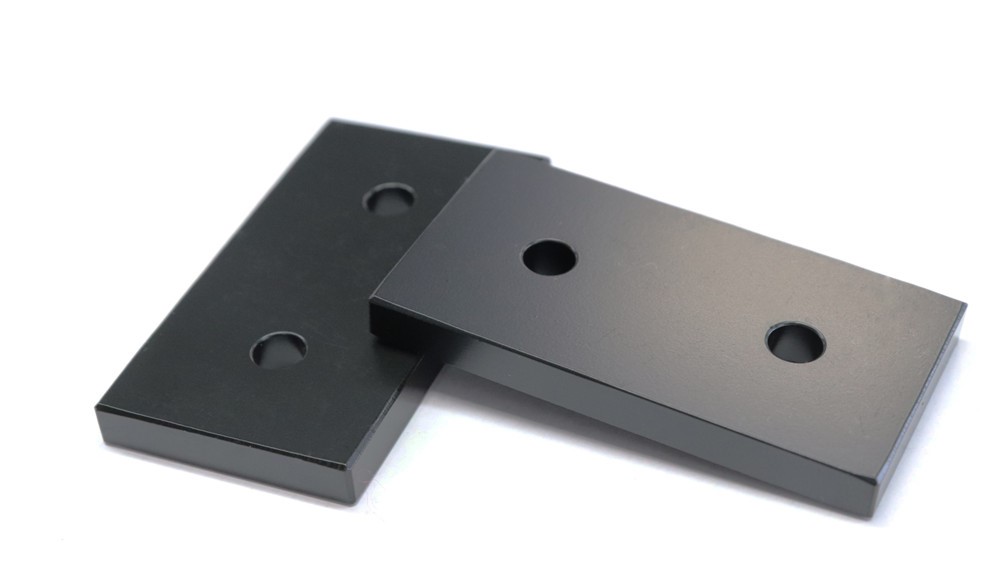

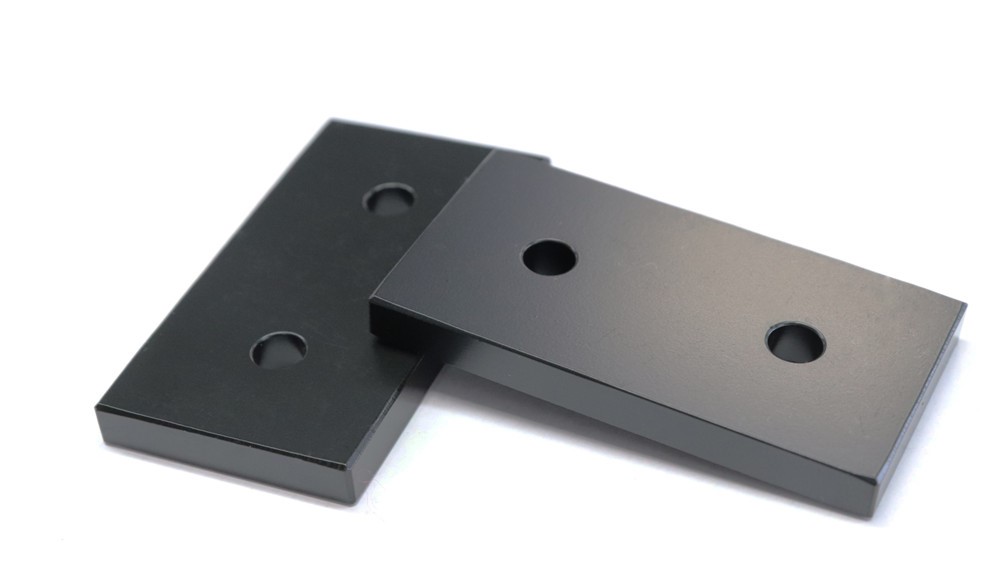

Customized NdFeB bonded compression magnets with holes

NdFeB bonded compression magnets are a useful magnet option for a variety of applications. Their ability to be produced in complex shapes and sizes, resistance to corrosion and demagnetization, and flexibility in magnetization direction make them a versatile and reliable choice. However, their lower magnetic energy product and higher production cost may make them less suitable for certain applications.

-

Customized NdFeB bonded compression magnets for Motors and generators

NdFeB bonded compression magnets are widely used in various applications, including motors and generators. These magnets are made by compressing a mixture of NdFeB powder and a high-performance polymer binder under high pressure, resulting in a strong, compact, and efficient magnet with excellent magnetic properties and dimensional stability.

-

Customized ring NdFeB bonded compression magnets for bearings

Ring NdFeB bonded compression magnets are an essential component in various industries, including aerospace, automotive, medical, and energy. These magnets offer exceptional performance in demanding applications, providing high magnetic strength, energy product, and superior dimensional stability. They are available in various sizes and shapes, including cylindrical, annular, and multi-pole ring magnets, providing designers and engineers with flexibility and versatility to create customized solutions for their applications.

-

High-Performance Injection Bonded Ferrite Magnets

Injection-molded ferrite magnets are a type of permanent ferrite magnet that is manufactured through the injection molding process. These magnets are created using a combination of ferrite powders and resin binders, such as PA6, PA12, or PPS, which are then injected into a mold to form a finished magnet with complex shapes and precise dimensions.

-

Durable and Reliable Injection Molded Ferrite Magnets

Injection molded ferrite magnets, bonded ferrite magnets, are those permanent ferrite magnets manufactured by the injection process. Permanent ferrite powders compounded with resin binders (PA6, PA12, or PPS), followed by injected through a mold, finished magnets have complex shapes and high dimensional accuracy.