Our Alnico Disc magnets do not have a protective coating, making them more susceptible to chipping and weathering. These magnets have a high-temperature tolerance and can resist demagnetization up to 540°C.

However, exposure to temperatures above 540°C will result in a permanent loss of magnetism. Additionally, these magnets are axially magnetized and are often referred to as raw magnets because they do not have any casing around them. They are used in a variety of applications, ranging from small sensors in electronics to large separation systems in high-temperature environments.

The features of these magnets include temperature stability in high-temperature applications, with a maximum working temperature of approximately 1000°F. While Alnico bar magnets can be ground to size, they cannot be machined conventionally.

We offer grinding services to meet your specific specifications. Compared to ceramic magnets, Alnico bar magnets have high residual induction and energy production, but they have a lower coercive force, making them more susceptible to demagnetization.

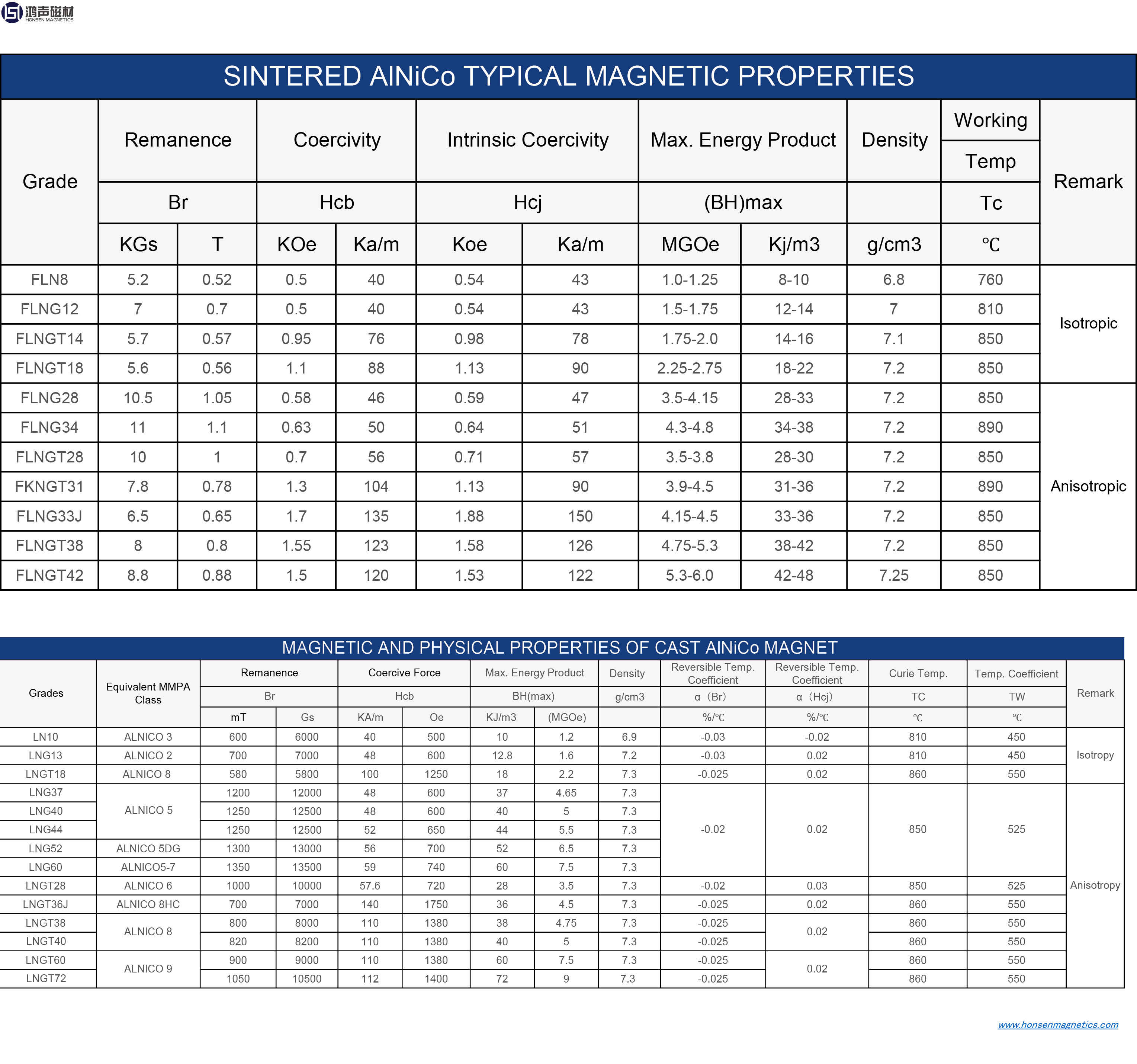

Our Alnico magnets are available in Grade 5, and we can supply Grade 8 upon request. For a comparison of different Alnico grades, please refer to our properties chart. When it comes to grinding and tolerances, Alnico is a hard and brittle material, which makes it unsuitable for drilling, tapping, or conventional machining. Close tolerances can be achieved through abrasive grinding and cutting. We have in-house cutting and grinding capabilities to meet your application requirements.

ALNICO magnets are composed of aluminum, nickel, cobalt, copper, and iron, making them ideal for high-heat applications. The maximum working temperature ranges from 975°F to 1020°F. We offer various sizes of AlNiCo magnets according to customer requests and designs.

To assist you further, please contact us with the shape, size, tolerance, and grade of AlNiCo magnets you require.

Honsen Magnetics is synonymous with quality and has a rich history of over ten years in the manufacture and sale of permanent magnets, magnetic components, and magnetic products. Our skilled team manages a comprehensive production line covering machining, assembly, welding, and injection molding. Renowned for providing quality yet affordable solutions, our products have won over discerning clients in Europe and the US. Our services are rooted in client-centric values, which have earned us a loyal and wide-ranging clientele. At Honsen Magnetics, we exceed magnetic expectations with innovative solutions and dedicated service.

- More than 10 years of experience in the permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a strong R&D team can provide perfect OEM&ODM service

- Have the certificate of ISO 9001, IATF 16949, ISO14001, ISO45001, REACH, and RoHs

- Strategic cooperation with the top 3 rare blank factories for raw materials

- High rate of automation in Production & Inspection

- Pursuing product consistency

- We only export qualified products to customers

- 24-hour online service with first-time response

We are committed to providing customers with forward-looking support and innovative, competitive products to enhance our market influence. Through technological innovation, we strive for growth and new market expansion driven by unique breakthroughs in permanent magnets and components. Our experienced R&D department, headed by a chief engineer, utilizes in-house expertise, maintains customer contacts and anticipates market trends. Independent teams oversee global projects, ensuring that research continues to progress.

Quality management is an integral part of our company spirit. We see quality as the heartbeat and compass of our organization. Our commitment goes beyond the surface - we intricately integrate our quality management system into our operations. Through this approach, we ensure that our products consistently meet and exceed our customers' requirements, shaping excellence together.

At Honsen Magnetics, our unwavering commitment depends on ensuring maximum customer satisfaction and safety. In addition to our exceptional products, we embrace a corporate culture that fosters the personal growth and professional advancement of our employees. Every member of our team is an important contributor to our progress and we firmly believe that developing their skills and wellbeing is key to our continued success.