Magnetic formwork systems can help increase efficiency, comfort, and safety for workers in the reinforced concrete industry. The prefabricated construction industry is growing steadily. Magnetic products such as formwork systems and ferrule insert magnets are used to secure inserts to steel formwork using magnets, eliminating the need for drilling. These innovative systems have revolutionized the production of precast concrete elements. The magnet can be directly embedded in the template, which is more convenient, efficient, and stable. Using the strong adhesion provided by the magnetic block, the formwork is firmly attached to the formwork, ensuring the stability of the fixed formwork system. The combination of steel formwork and magnetic blocks eliminates any possibility of movement as even a slight movement can cause deformation of the formwork system. Magnetic formwork systems are user-friendly, require a minimal learning curve, and they make a significant contribution to safety and security. The prefabricated construction industry is stable. With a compatible pry bar, the formwork magnets can be easily lifted to easily remove the steel formwork from the formwork. Since the magnets are located in the steel formwork grooves, the presence of concrete residue or dirt does not pose a risk of damage to the formwork system.

Our precast concrete form magnets consist of steel formwork and embedded magnets.

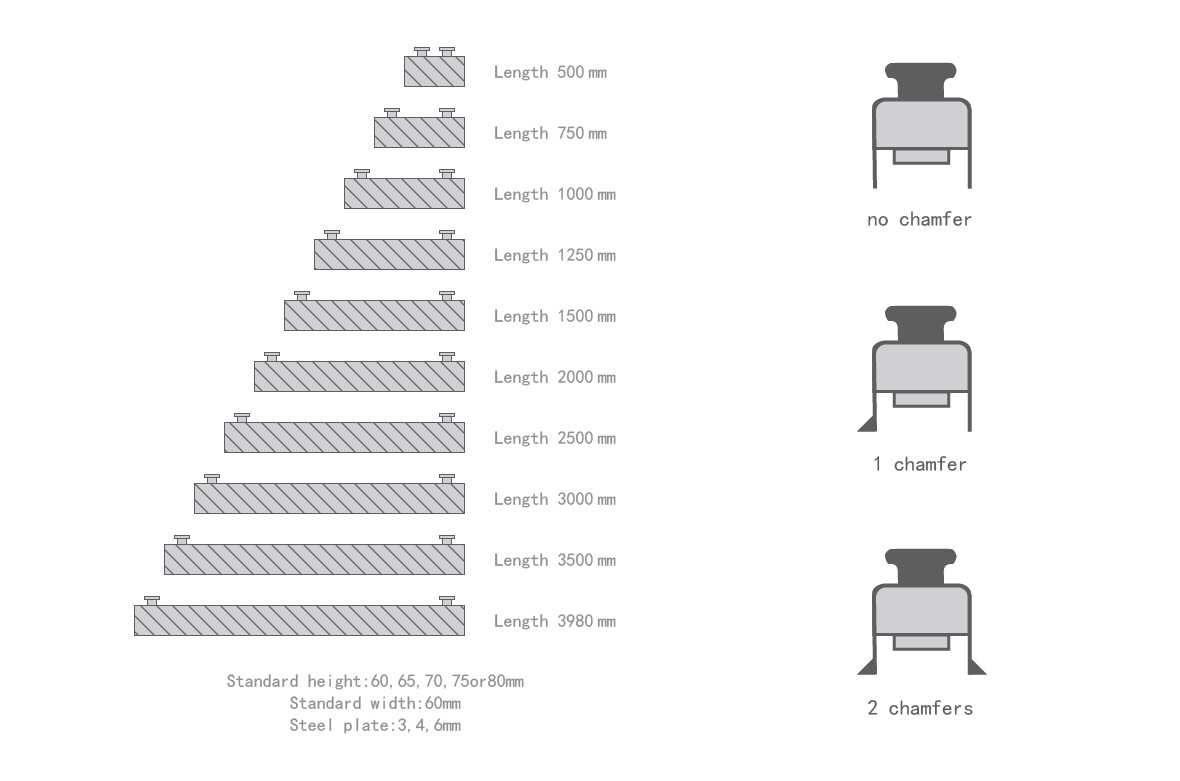

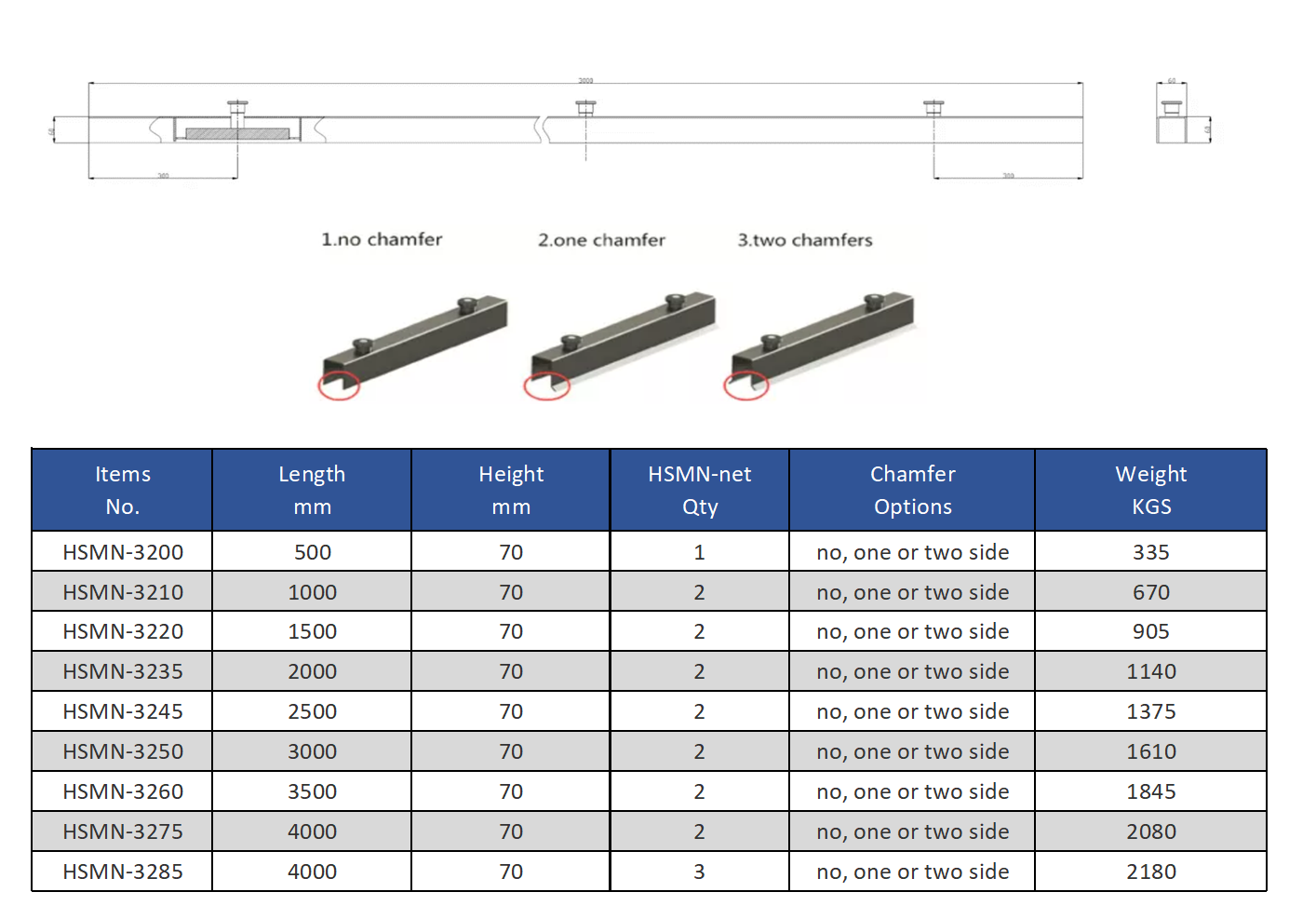

U-shaped concrete formwork systems are tailored to specific specifications. Customers can choose the desired size with or without grooves and whether they prefer one chamfer, two chamfers, or no chamfer.

Our magnetic formwork systems are made with high-performance magnetic inserts and high-quality steel. The system can be equipped with chamfers on both sides, on one side, or without chamfers at all.

We are able to configure the system to meet the exact length and height requirements of our customers. We can help you find the right solution for your industrial construction needs.

- Easy to locate

- Compatible with existing formwork robots or can be activated with the push of a button

- User-friendly Able to withstand high temperatures

- Corrosion resistant Suitable for making cell panels and double walls

- Custom sizes and heights available upon request

- The number of magnets is adjusted for each specific template task

- Designed for long-lasting, reliable, durable performance

- Easy removal with a corresponding pry bar

- Complete formwork system resists damage from concrete residue and dirt

- Choose from 0 chamfer, 1 chamfer and 2 chamfer options

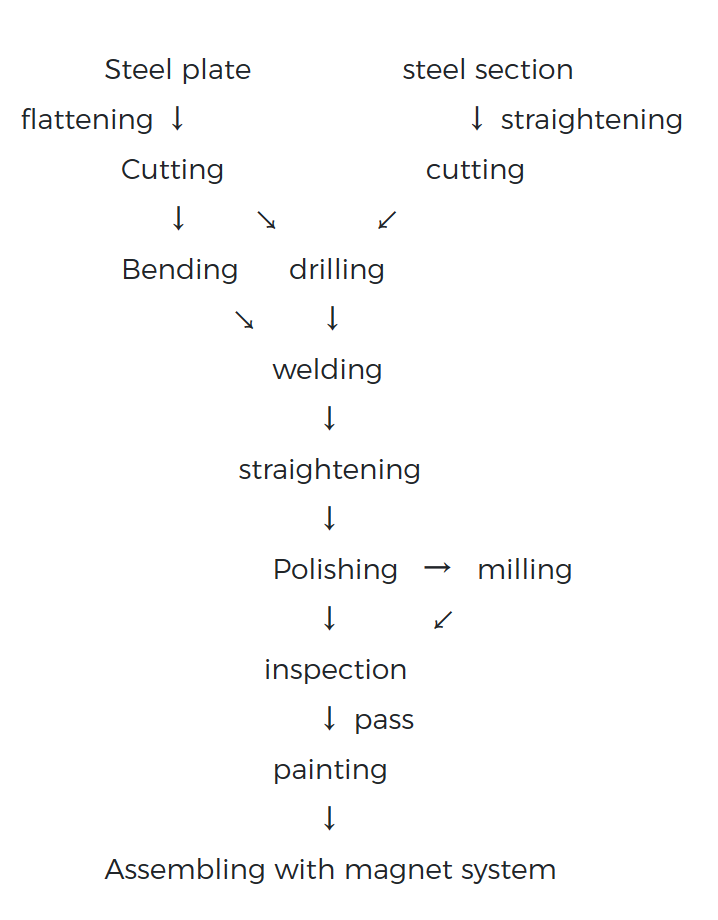

The U-shaped concrete formwork system is manufactured using iron plates with the help of a unique folding machine. The folding mechanism is responsible for creating the option of double-groove chamfer, single-groove chamfer, or no chamfer. We also use hand soldering equipment to solder formwork magnets in sizes between 2-3 m. Our production facilities are capable of producing template magnets with a height exceeding 100mm.

Below is an overview of the special handling we employ during production to ensure the longevity of the magnetic formwork systems you purchase from us. We use a combination of aluminum alloy and stainless steel for their superior durability and ability to withstand extreme temperatures and wear. Additionally, we employ special treatments to protect our systems from rust and corrosion. These systems are very easy to maintain because we have preprocessed them.

Q235A carbon steel has high magnetic properties and is more cost effective than stainless steel. It is commonly used in chemical surface treatment. The purpose of blackening treatment is to form an oxide film on the metal surface to isolate it from the air and provide a strong anti-rust barrier.

Some customers are concerned about the oxide layer affecting the cement surface. In order to ensure the safety of all aspects of the cement surface, we have carried out a unique polishing treatment on the Q235A carbon steel.

The aluminum alloy formwork magnet consists of an aluminum alloy formwork and an embedded magnet block. Thanks to its unique processing technology, the aluminum alloy formwork is extremely strong. It presents the least risk of bending, galling, or warping compared to steel or stainless steel. In addition, aluminum alloy has excellent consistency and stability. The reduced weight of the formwork also makes it easier to handle and use.

Stainless steel formwork magnets include stainless steel formwork and embedded magnet blocks. It is lightweight and easy to operate with the robotic arm.

Honsen Magnetics has a rich heritage of over ten years in the manufacture and trading of Permanent Magnets, Magnetic Components and Magnetic Merchandise. Our skilled employees have a complete production line, handling processes such as machining, assembly, welding and injection molding. Our reputation is built on reasonable prices, high-quality products and customer-centric concepts, and enjoys a high reputation in Europe and America.

- More than 10 years experience in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a complete production line from machining, assembling, welding, injection molding

- Have a strong R&D team can provide perfect OEM&ODM service

- Skilled workers & continuous improvement

- We only export qualified products to customers -

- Fast shipping & worldwide delivery

- Serve ONE-STOP-SOLUTION ensure efficient & cost-effective purchasing

- 24-hour online service with first-time response

Our firm aim is to provide customers with forward-looking assistance and innovative, competitive products, thereby strengthening our position in the market. Driven by breakthrough discoveries in permanent magnets and components, our focus is on growth through technological advancement and access to untapped markets. A strong R&D department, led by a chief engineer, leverages in-house capabilities, cultivates customer relationships, and accurately forecasts market trends. An independent panel vigilantly monitors initiatives worldwide, maintaining a steady stream of ongoing research work.

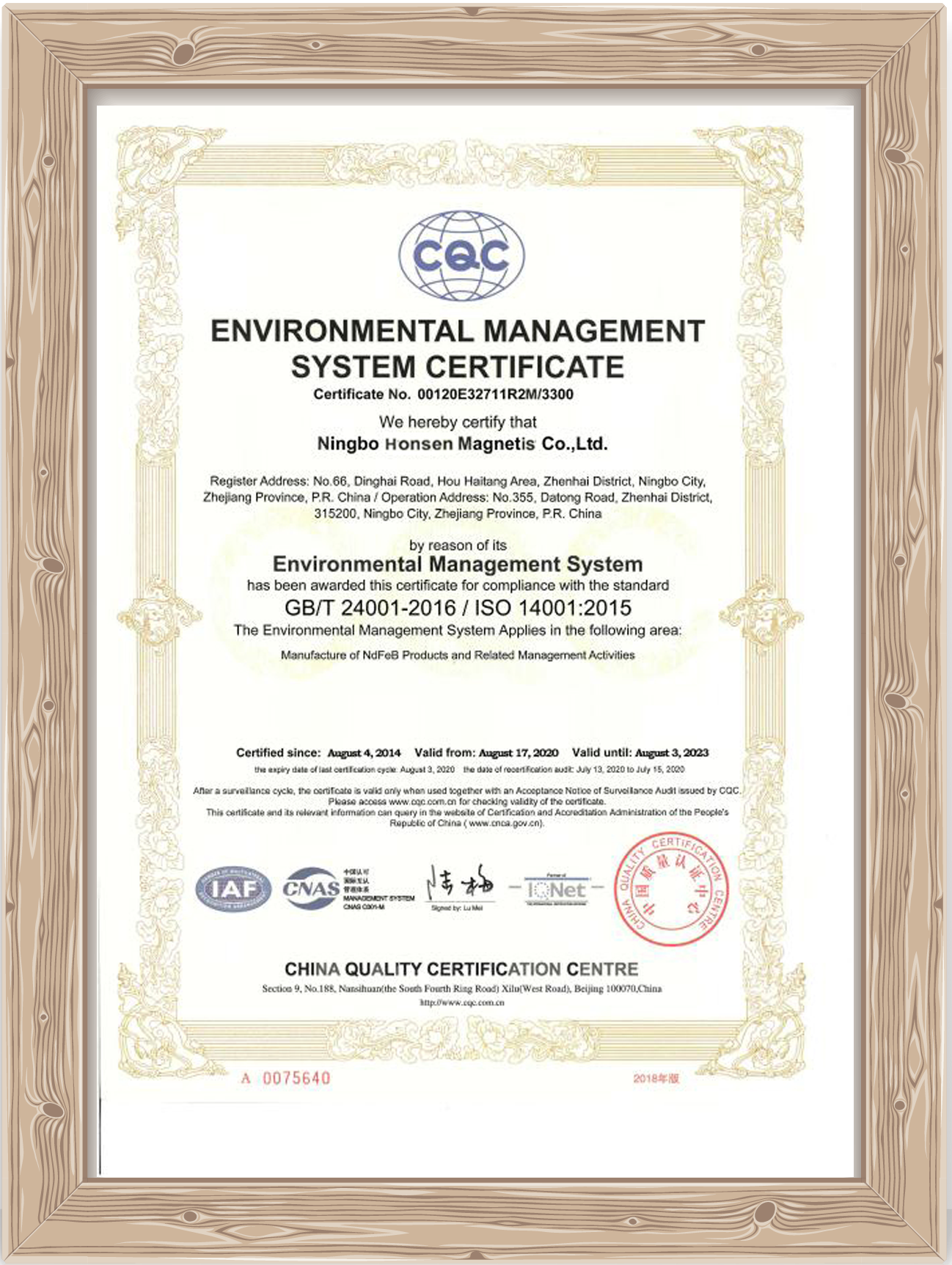

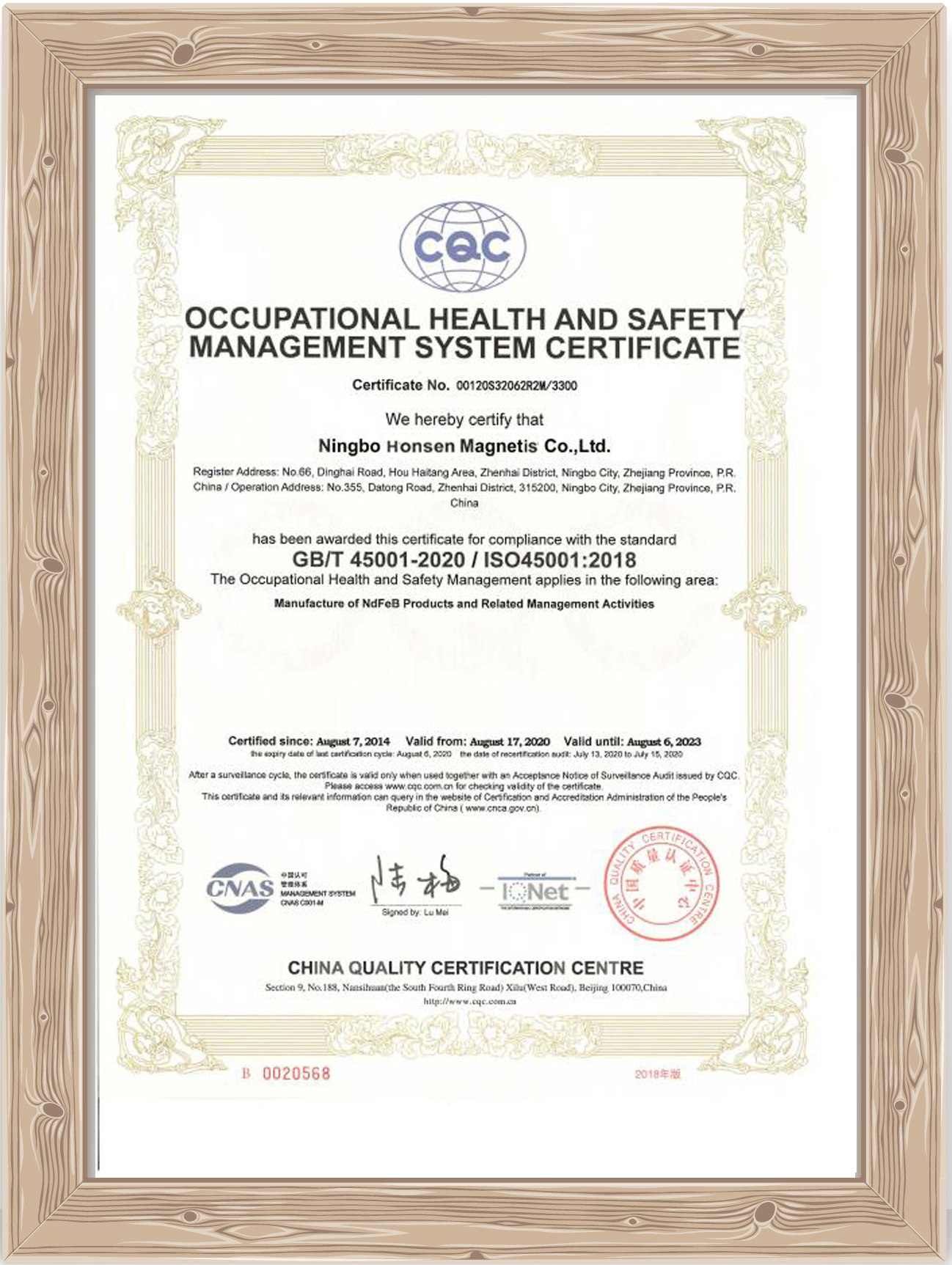

Quality management is the cornerstone of our company values. We firmly believe that quality is the lifeblood and compass of an enterprise. Our dedication goes beyond traditional approaches to quality management - it's woven into our operations. By utilizing this approach, we guarantee that our products consistently meet and exceed our customers' requirements, setting new benchmarks in satisfaction.

Our company is deeply rooted in quality management. We believe that quality is not just a concept, but the life force and guiding principle of our organization. Our approach goes beyond the surface - we seamlessly integrate our quality management system into our operations. Through this approach, we ensure that our products consistently meet and exceed our customers' expectations, reflecting our commitment to excellence.