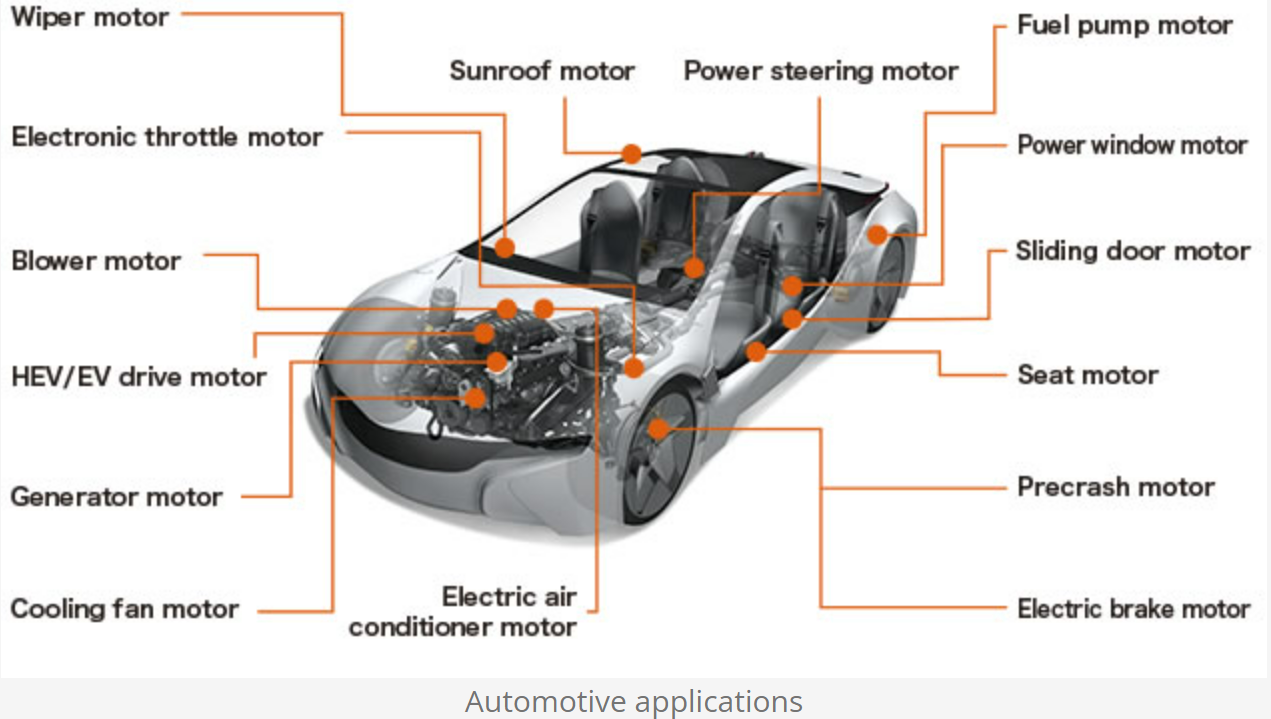

Injection molded magnetic steel auto parts are commonly used in applications such as speed sensors, angle sensors, and power steering motors. They offer high magnetic strength and energy density, which makes them ideal for use in these types of applications. Additionally, they are resistant to demagnetization and have a high resistance to corrosion, which makes them suitable for use in harsh environments.

One of the key benefits of injection molded magnetic steel auto parts is their ability to be mass-produced at a low cost. The injection molding process allows for high-volume production and results in parts that are consistent in quality and performance. This makes them an attractive option for automotive manufacturers who need to produce large quantities of parts while keeping costs low.

Overall, injection molded magnetic steel auto parts are a reliable and cost-effective solution that delivers superior magnetic properties and dimensional accuracy, making them an excellent choice for a variety of automotive applications. With their ability to be mass-produced at a low cost, they are an ideal solution for manufacturers looking to improve the efficiency and performance of their products.

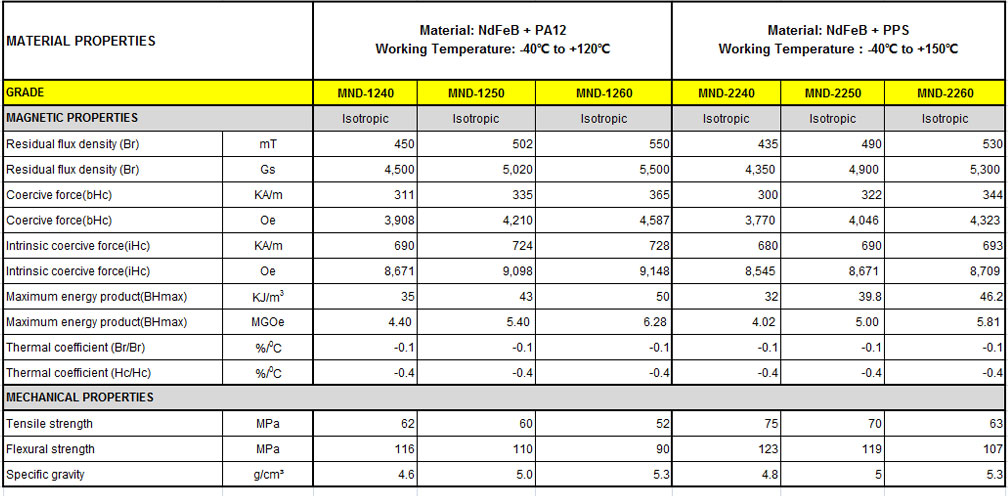

Performance Table:

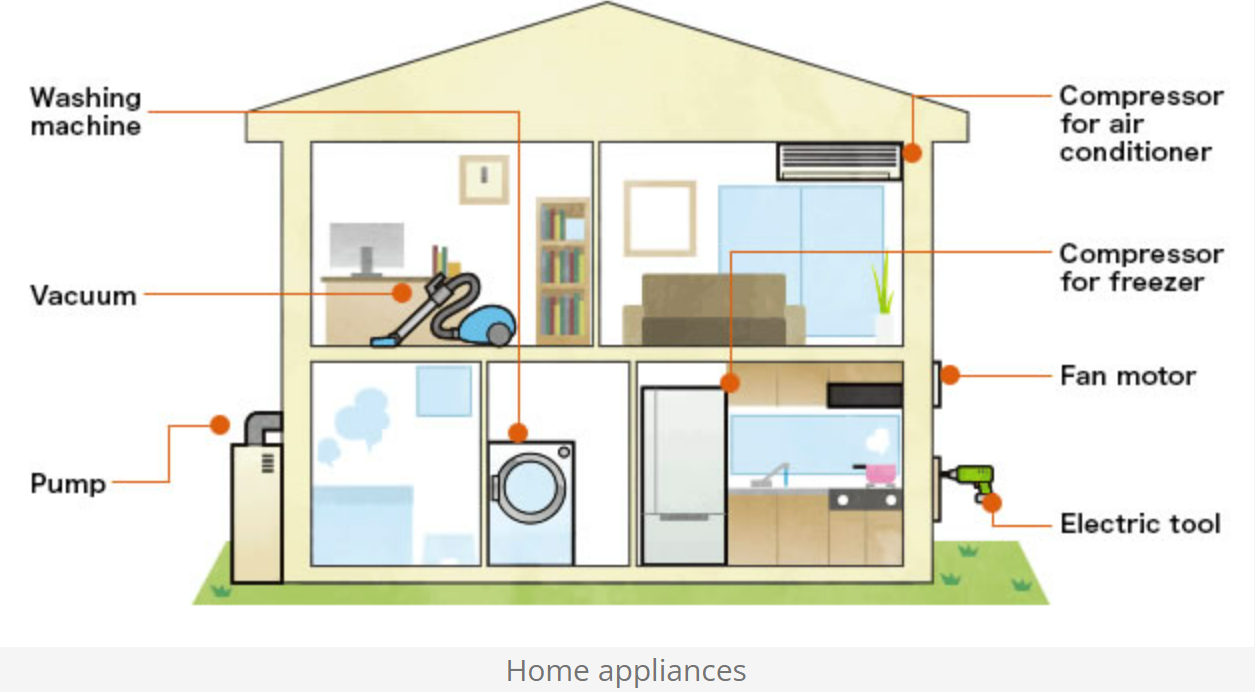

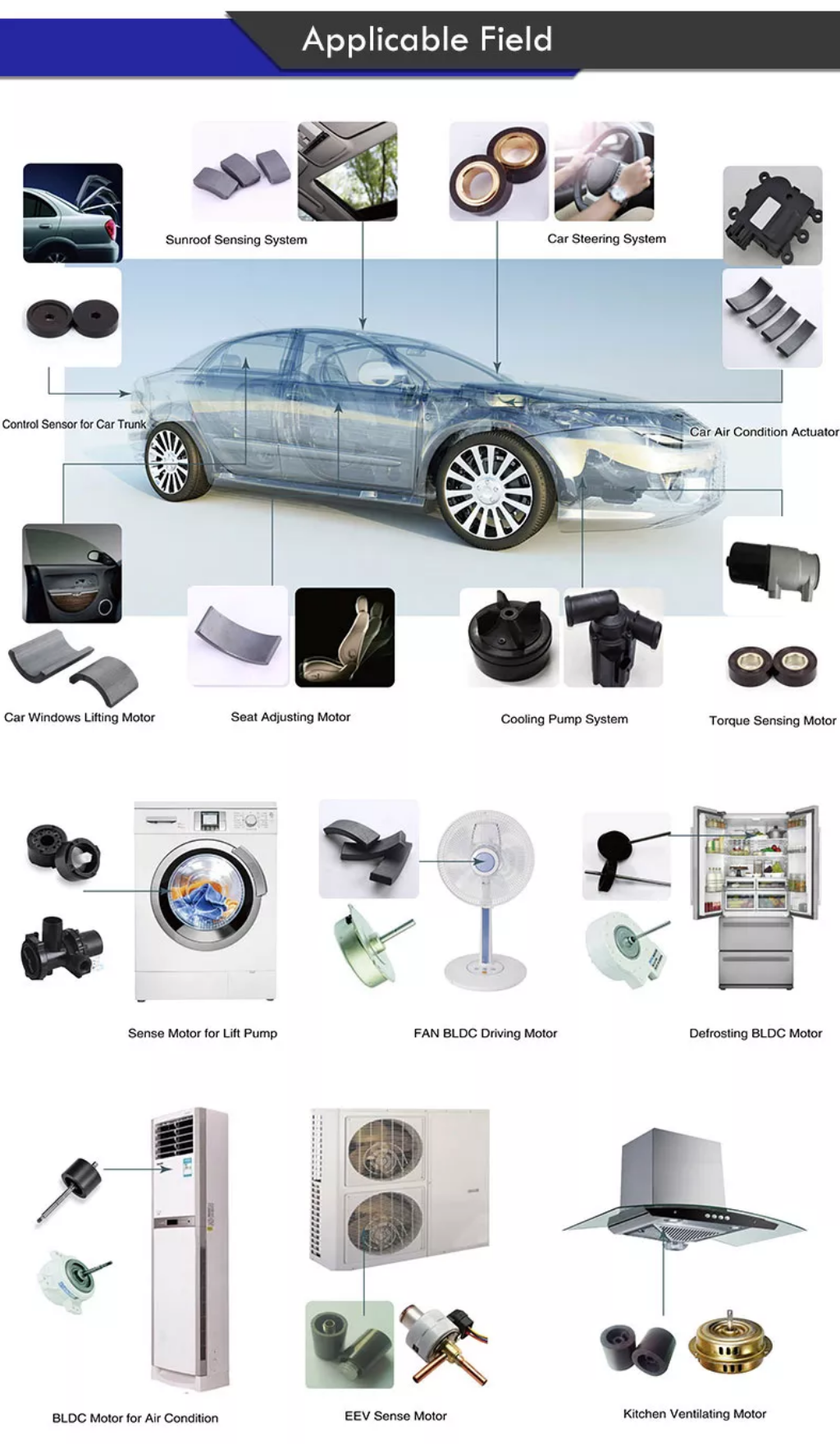

Application: