Sintered NIB Magnets

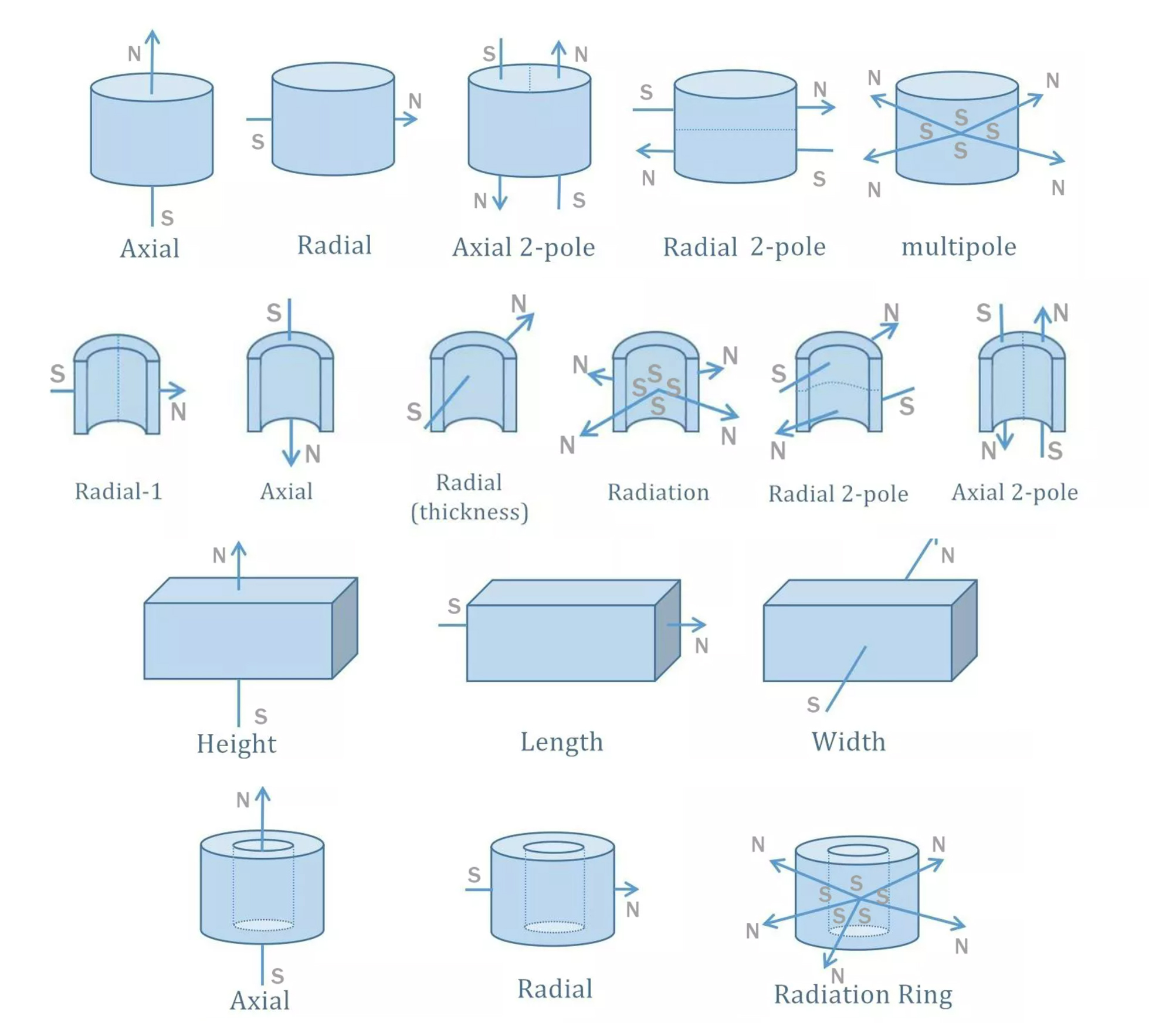

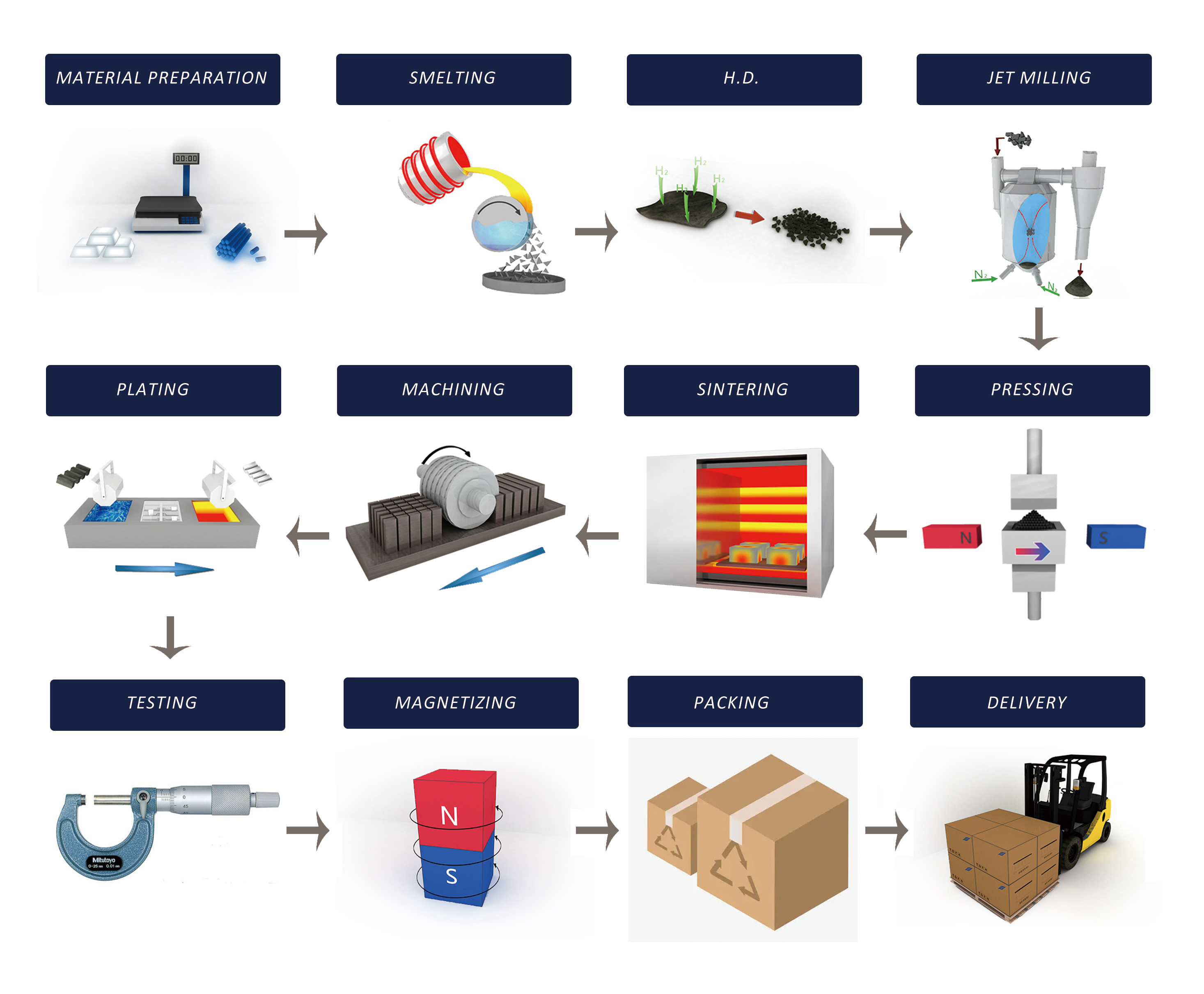

Sintered NIB magnets have the highest strength but are limited to relatively simple geometries and can be brittle. They are made by pressure forming the raw materials into blocks, which then go through a complex heating process. The block is then cut to shape and coated to prevent corrosion. Sintered magnets are typically anisotropic, which means they have a preference for the direction oftheir magnetic field. Magnetizing a magnet against the "grain” will reduce the strength ofthe magnet by up to 50%. Commercially availabe magnets are always magnetized in the preferred direction ofmagnetization. Radial Oriented NdFeB Ring Magnet

Demagnetization

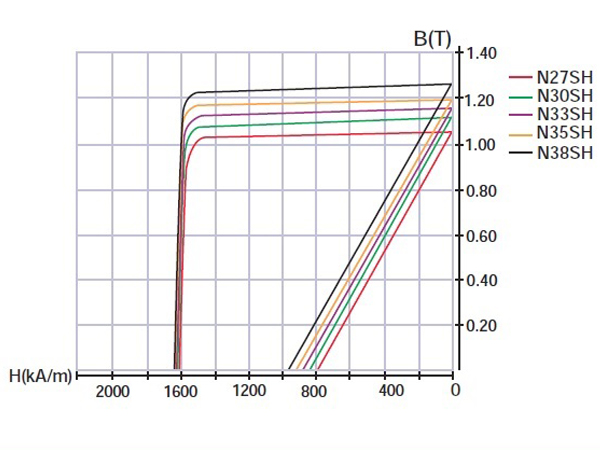

NIB magnets really are permanent magnets, as they lose thein magnetism, or degauss naturally, at approximately 1% per century.Theygenerally operate within the temperature range of-215°Fto 176°F(-138°C to 80°℃). For applications that require a broader temperature range, Samarium Cobalt (SmCo) magnets are used.

Coatings

Because uncoated sintered NIB will corrode and crumble with exposure to the atmosphere, they are sold with a protective coating. The most common coating is made of nickel, though other commercially available coatings provide resistance to high temperature, high humidity, salt spray, solvents and gases.

Grade

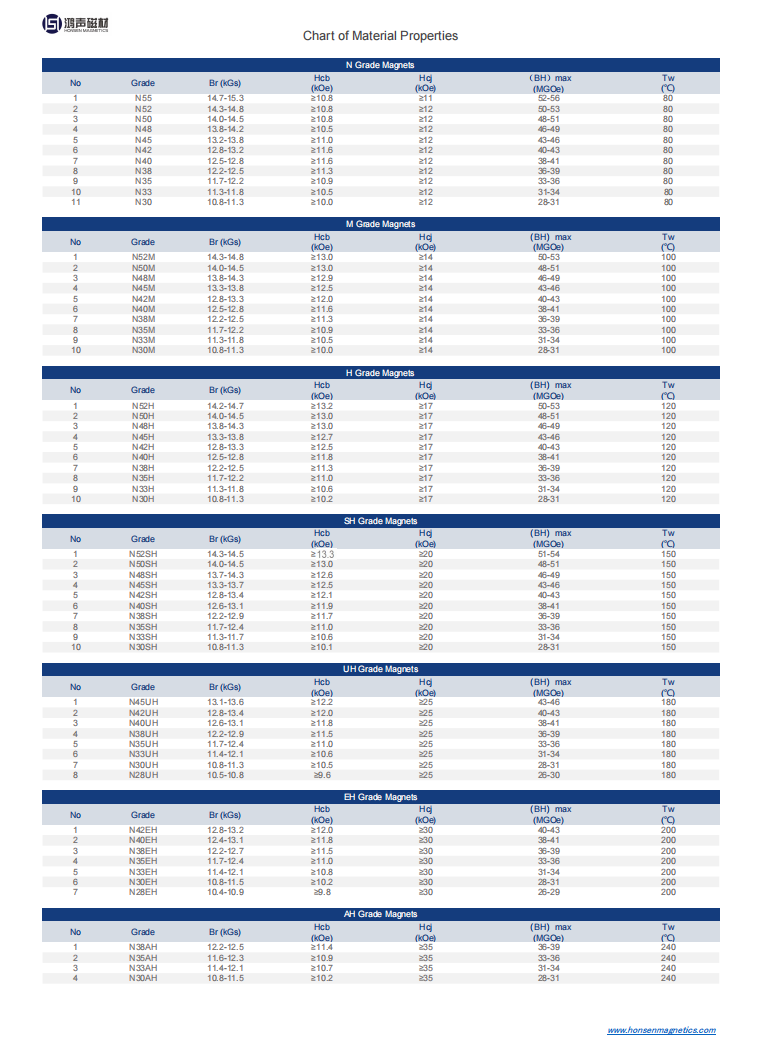

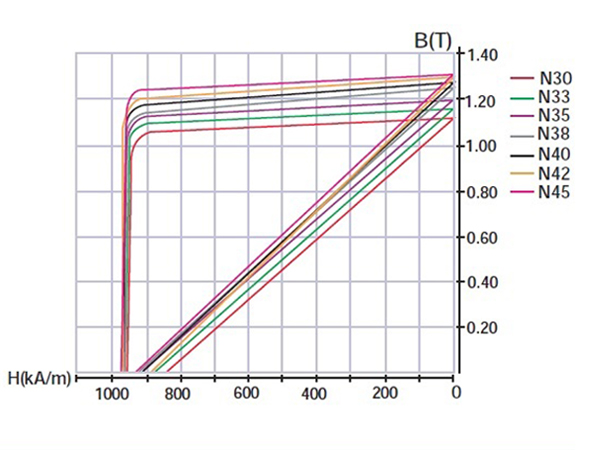

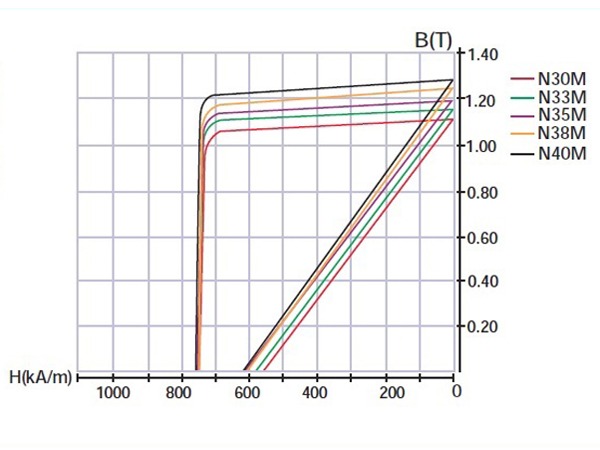

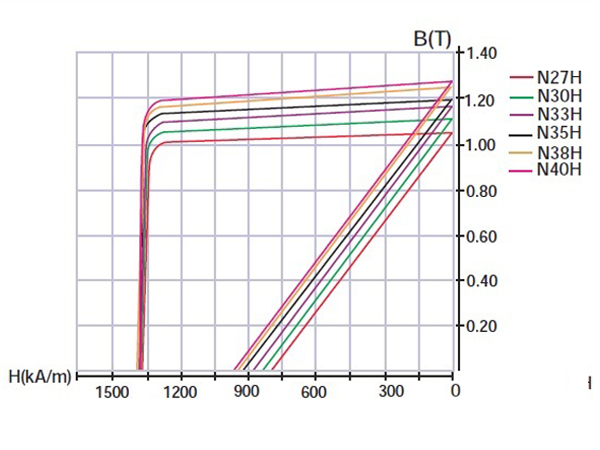

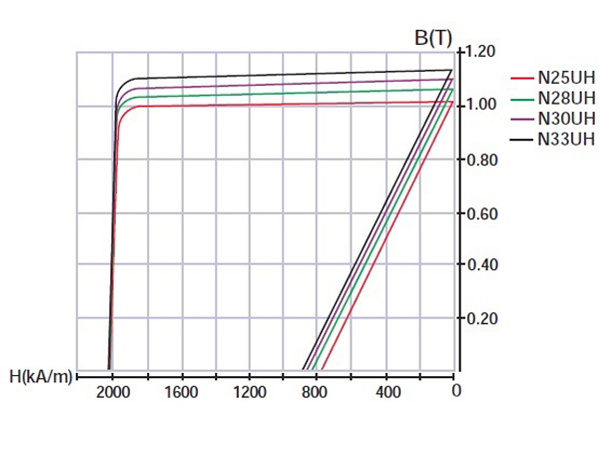

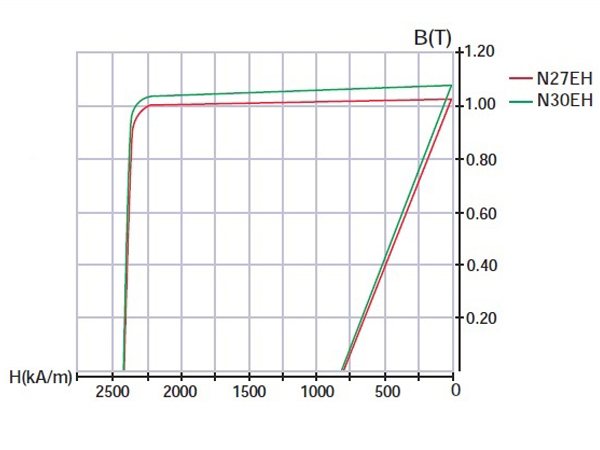

NIB magnets come in different grades, which correspond to the strength oftheir magnetic fields, ranging from N35 (weakest and least expensive) to N52 (strongest, most expensive and more brittle).An N52 magnet is approximately 50% stronger than an N35 magnet(52/35 = 1.49). In the Us, it is typical to find consumer grade magnets in the N40 to N42 range. In volume production,N35 is often used ifsize and weight are not a major consideration as it is less expensive. f size and weight are critical factors, higher grades are typically used. There is a premium on the price of the highest grade magnets so it is more common to see N48 and N50 magnets used in production versus N52.

Detailed parameters

Product Flow Chart

Why Choose Us

Company Show

Feedback