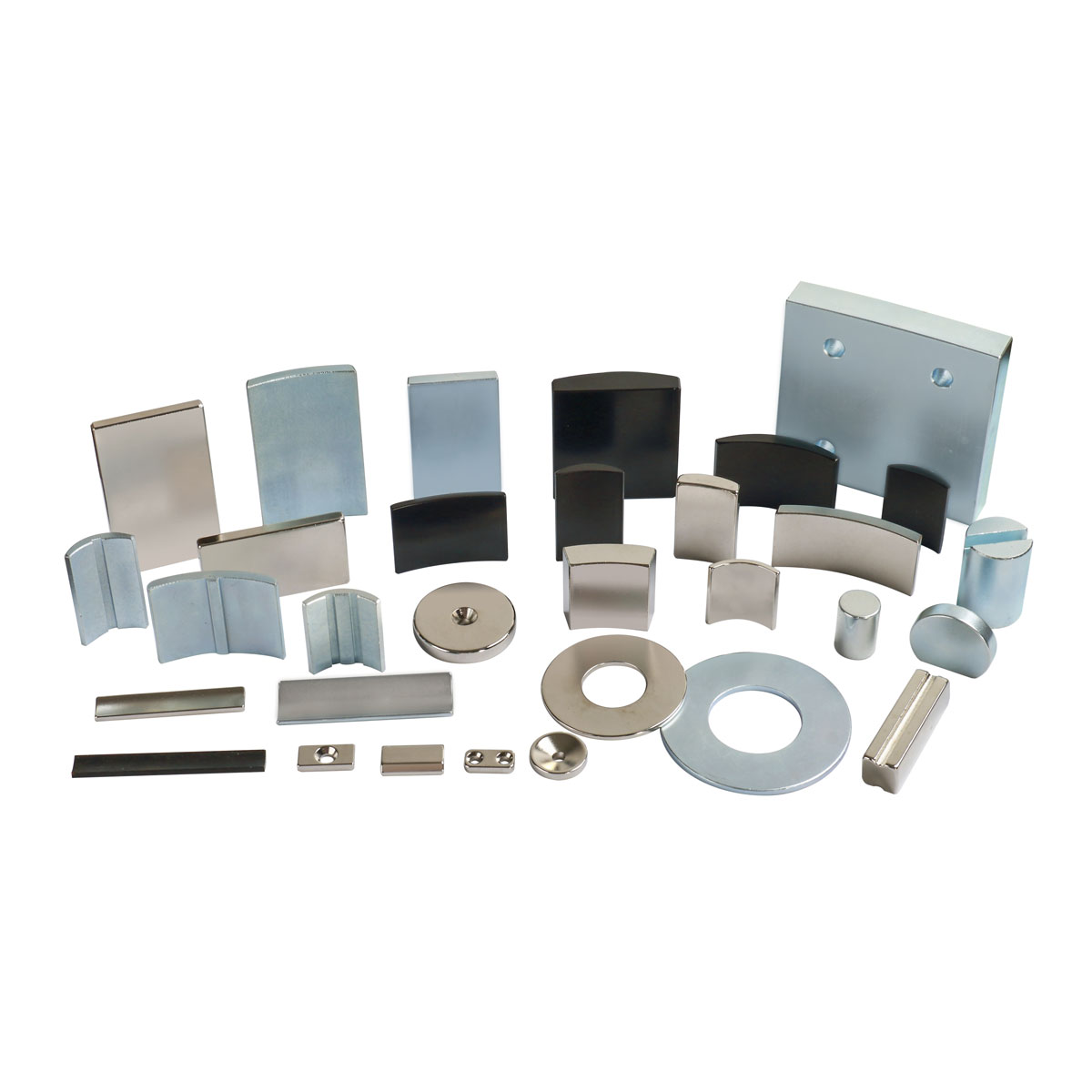

Custom Magnets

-

N38H Customized NdFeB Magnet NiCuNi Coating Max Temperature 120℃

Magnetisation Grade: N38H

Material: Sintered Neodymium-Iron-Boron (NdFeB, NIB, REFeB, Neoflux, NeoDelta), Rare Earth Neo

Plating / Coating: Nickel (Ni-Cu-Ni) / Double Ni / Zinc (Zn) / Epoxy (Black/Gray)

Tolerance: ±0.05 mm

Residual Magnetic Flux Density (Br): 1220-1250 mT (11.2-12.5 kGs)

Energy Density (BH)max: 287-310 KJ/m³ (36-39 MGOe)

Coercivity Force (Hcb): ≥ 899 kA/m ( ≥ 11.3 kOe)

Intrinsic Coercivity Force (Hcj): ≥ 1353 kA/m ( ≥ 17kOe)

Maximum Operation Temperature: 120 °C

Delivery Time: 10-30 days -

Magnetic Name Badge Automatic Production

Product Name:Magnetic Name Badge

Material: Neodymium Magnet+Steel Plate+Plastic

Dimension: Standard or customized

Color: Standard or customized

Shape: Rectangular, Round or customized

The Magnetic Name Badge belongs to a new type of badge. The Magnetic Name Badge uses magnetic principle to avoid damaging clothes and stimulating skin when wearing ordinary badge products. It is fixed on both sides of clothes by the principle of opposite attraction or magnetic blocks, which is firm and safe. Through the rapid replacement of labels, the service life of products is greatly extended.

-

Sintered NdFeB Block / Cube / Bar Magnets Overview

Description: Permanent Block Magnet, NdFeB Magnet, Rare Earth Magnet, Neo Magnet

Grade: N52, 35M, 38M, 50M, 38H, 45H, 48H, 38SH, 40SH, 42SH, 48SH, 30UH, 33UH, 35UH, 45UH, 30EH, 35EH, 38EH, 42EH etc

Applications: EPS, Pump Motor, Starter Motor , Roof Motor, ABS sensor, Ignition Coil, Loudspeakers etc Industrial Motor, Linear Motor, Compressor Motor, Wind turbine, Rail Transit Traction Motor etc.

-

Super Strong Neo Disc Magnets

Disc Magnets are the most common shaped magnets used in today’s major market for its economic cost and versatility. They are used in numerous industrial, technical, commercial and consumer applications due to their high magnetic strength in compact shapes and round, wide, flat surfaces with large magnetic pole areas. You’ll get an economic solutions from Honsen Magnetics for you project, contact us for details.

-

Neodymium Cylinder/Bar/Rod Magnets

Product Name: Neodymium Cylinder Magnet

Material: Neodymium Iron Boron

Dimension: Customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Magnetization Direction: As per your request

-

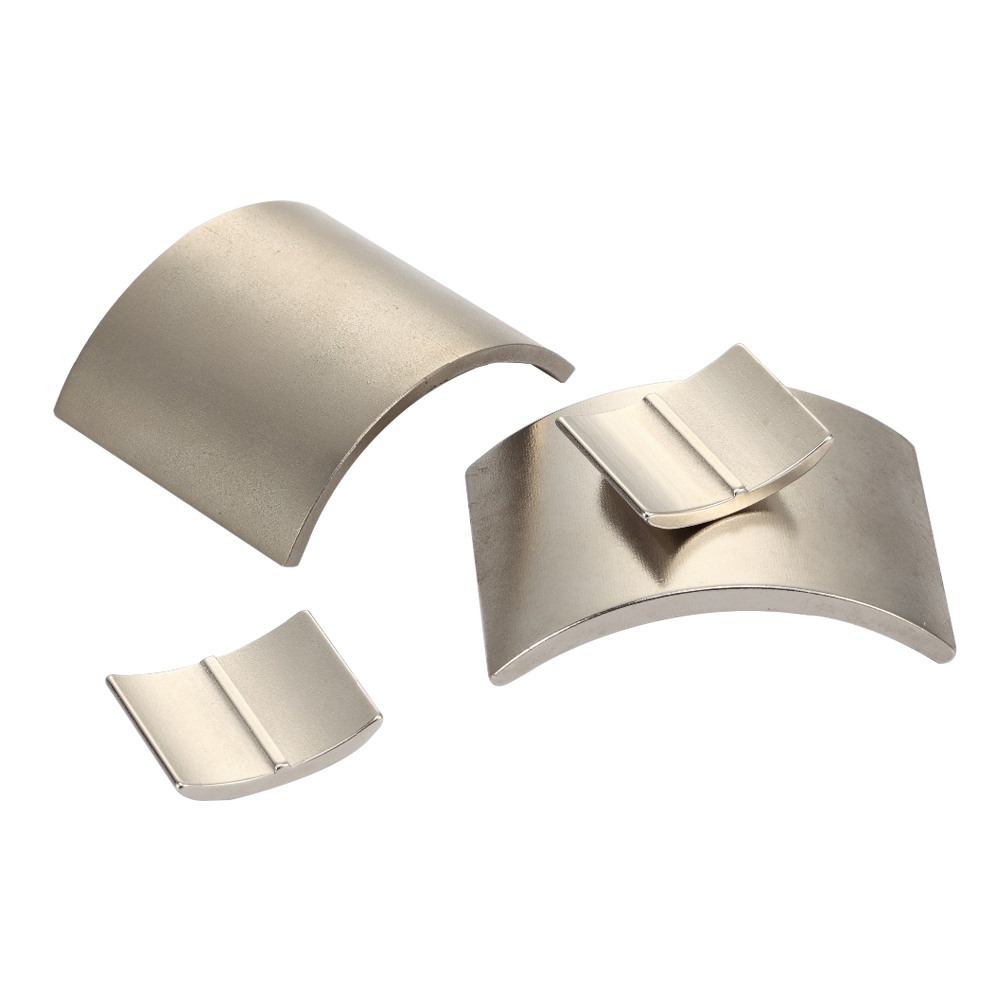

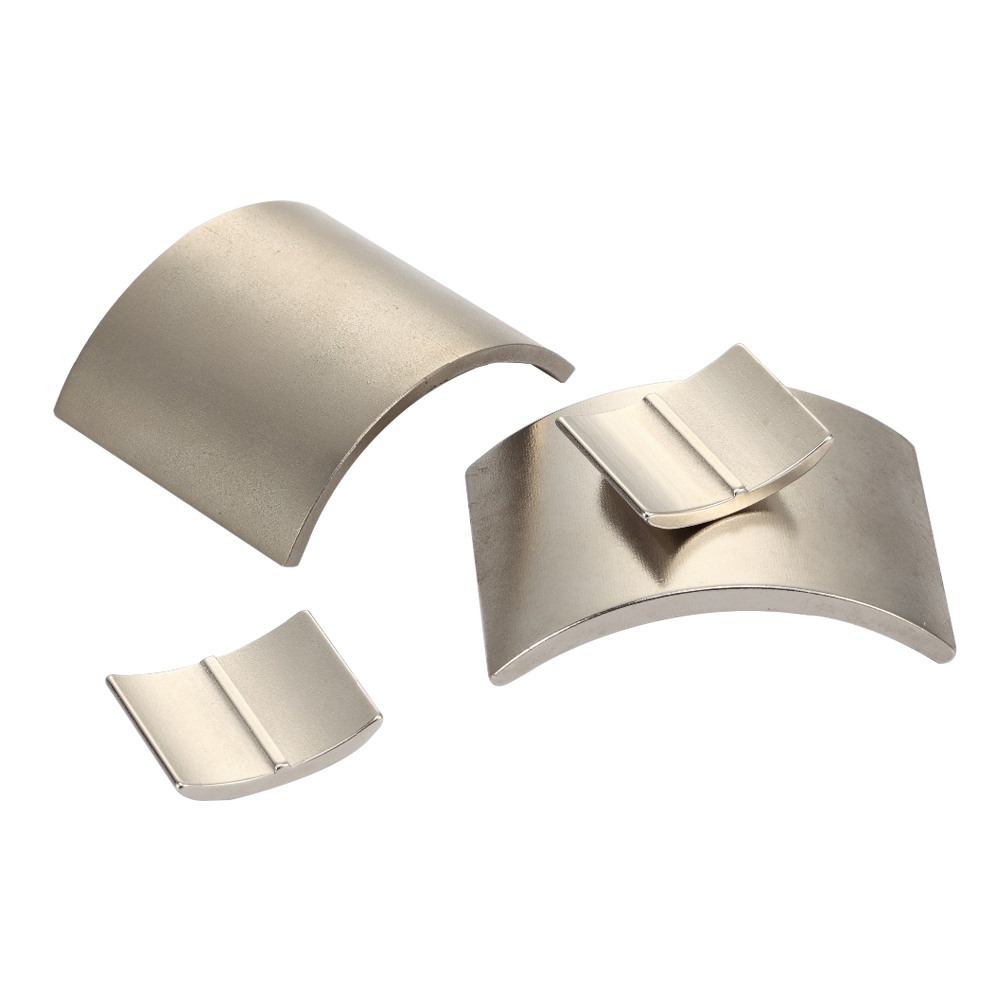

Neodymium (Rare Earth) Arc/Segment Magnet for Motors

Product Name: Neodymium Arc/Segment/Tile Magnet

Material: Neodymium Iron Boron

Dimension: Customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Magnetization Direction: As per your request

-

Countersunk Magnets

Product Name: Neodymium Magnet with Countersunk/Countersink Hole

Material: Rare Earth Magnets/NdFeB/ Neodymium Iron Boron

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Customized -

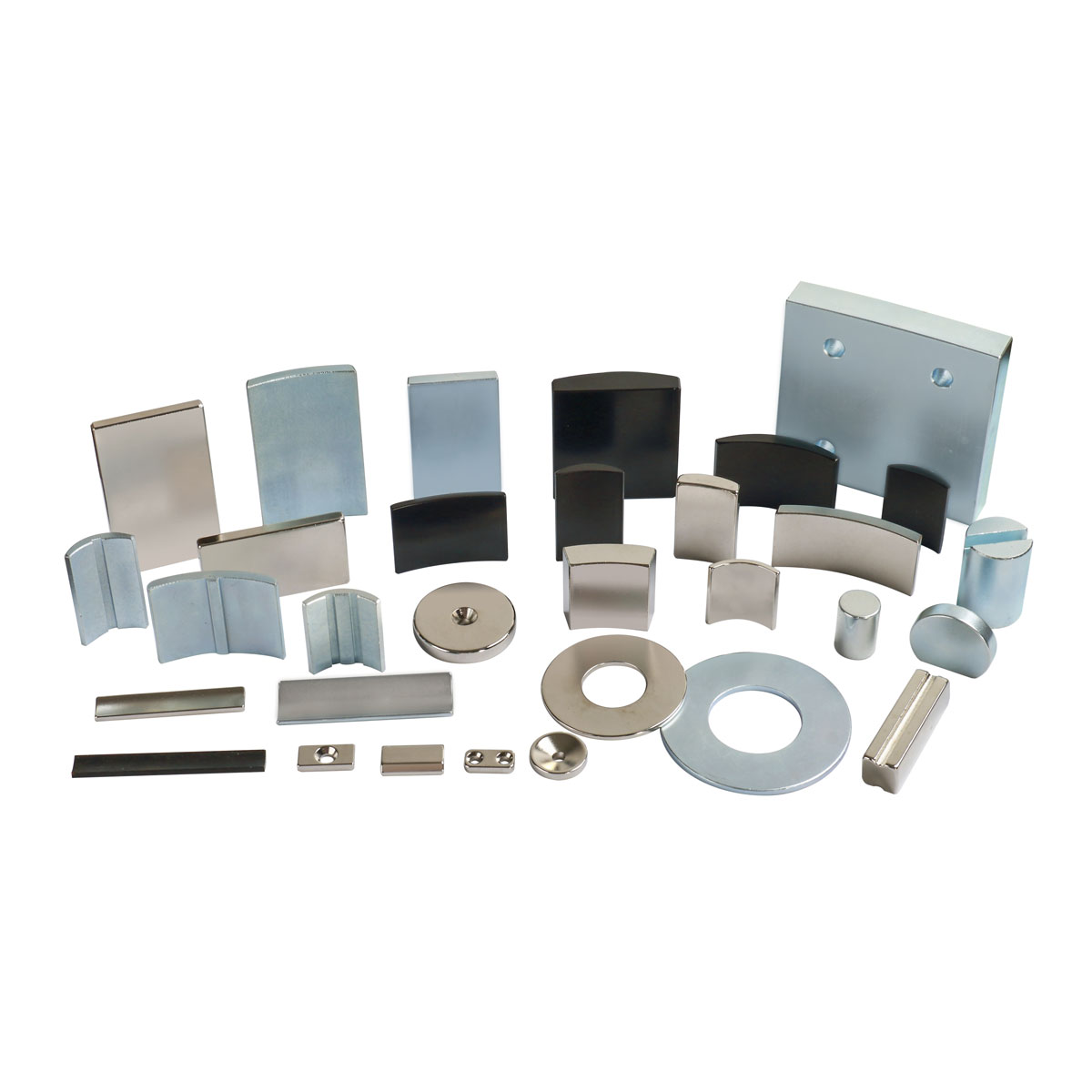

Custom Neodymium Iron Boron Magnets

Product Name: NdFeB Customized Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: As per your request

Lead time: 7-15 days

-

Coatings & Platings Options of Permanent Magnets

Surface Treatment: Cr3+Zn, Color Zinc, NiCuNi, Black Nickel, Aluminium, Black Epoxy, NiCu+Epoxy, Aluminium+Epoxy, Phosphating, Passivation, Au, AG etc.

Coating Thickness: 5-40μm

Working Temperature: ≤250 ℃

PCT: ≥96-480h

SST: ≥12-720h

Please contact our expert for coating options!

-

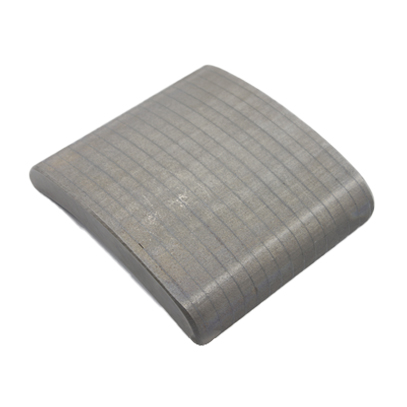

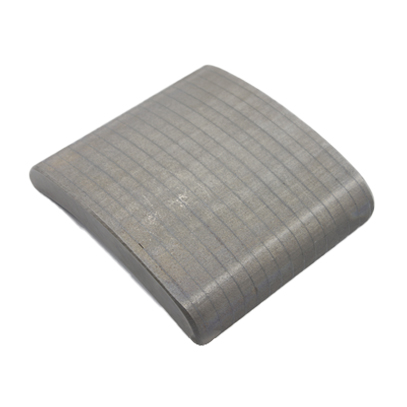

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

Neodymium Magnets for Household Appliances

Magnets are widely used for speakers in TV sets, magnetic suction strips on refrigerator doors, high-end variable frequency compressor motors, air conditioning compressor motors, fan motors, computer hard disk drives, audio speakers, headphone speakers, range hood motors, washing machine motors, etc.